Insights on Insect Protein in the Food and Beverage Segment

Food and Nutrition

Food and Nutrition

Several census statistics have suggested that the world population will reach over 9 billion by 2050. Due to the drastic increase in population, there will be a requirement for doubled food production and alternative food provisions. Alarmingly, global warming, climate change, and the environmental destruction from industrial development are gradually decreasing the avenues for food production worldwide which will negatively affect food production. In light of the worsening resource shortage, several food alternatives have been proposed, with insects receiving the most attention.

Insects have been historically consumed and accepted as food in many regions like India, China, Indonesia, Korea, Africa, and Thailand providing sufficient nutritional value for humans. Although in the Western civilization, the acceptance of insects as food has not been very promising in recent years Europe and the United States have the fastest-growing edible-insect industry. Insects have many unfolded facts like greater food conversion efficiency and produce lower greenhouse gas (GHG) emissions while requiring less water and land as compared to sources of protein in traditional animal husbandry. The consumption of insects, therefore, contributes positively to the environment, food and nutritional security, and healthy life for present and future generations.

Nutritional Facts of Edible Insects as a Food Alternative

Insects are extremely rich in protein and vitamins than even meat and chicken eggs. On average, the protein content of edible insects ranges 35%–60% dry weight or 10%–25% fresh weight, which is higher than plant protein sources, including cereal, soybeans, and lentils. Edible insects in Orthoptera (crickets, grasshoppers, locusts) are particularly protein-rich. The insect protein digestibility is 77%–98% without the exoskeleton. The second-largest component of insect nutrient composition is fat. Lepidoptera (caterpillars), Blattodea (cockroaches), Isoptera (termites), Hemiptera, and Coleoptera (beetles, grubs) have the averaged fat content of 13.41%, 27.66%, 29.90%, 32.74%, 30.26%, and 33.40%, respectively. Larvae and pupae have more fat than adult insects and females are fatty than males.

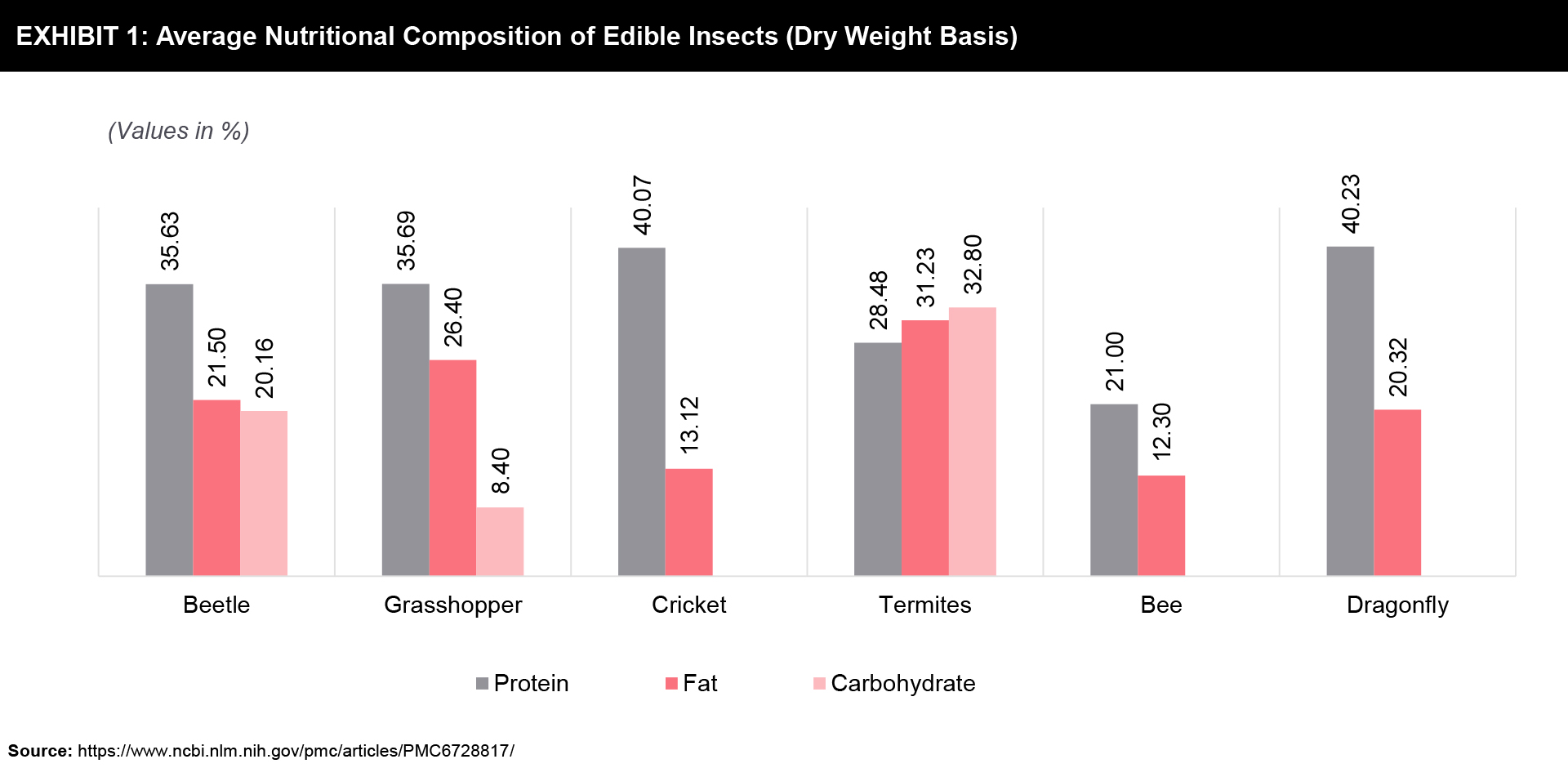

The fatty acid profiles of insects are also dependent on species and diet, although insects generally have more unsaturated fatty acids (UFA) compared to saturated fatty acids (SFA). On average, Hymenoptera (ants, bees, and wasps) and 41.97% for Isoptera (termites) have 30.83% and 41.97% SFA, respectively. Carbohydrates in insects mainly exist in two forms chitin and glycogen. The average carbohydrate content of edible insects ranges from 6.71% (stink bug) to 15.98% (cicada). Exhibit 1 depicts the average nutritional composition of edible insects based on their dry weight.

Some insects like grasshoppers, crickets, termites, and mealworms are rich in iron, zinc, calcium, copper, phosphorus, magnesium, and manganese. Most edible insects have similar iron content to beef. The investigations of vitamin content are also insufficient, but available data indicate that edible insects contain carotene, vitamin B1, B2, B6, C, D, E, and K and in particular, Orthoptera and Coleoptera are rich in folic acid.

Barriers of Edible Insects as a Food Alternative

Although only 0.2% of insects are harmful to human life, the persistent discernments of harmful insects contribute to the disinclination in eating insects. Further cultural attitudes also pose a barrier to adopting entomophagy. Some studies have found that insects have the same capacity to trigger allergic reactions as do crustaceans like shrimp and lobster. There is a possibility for a small amount of microbial fauna and spore-bearing bacteria to find their way into farmed bugs that would be used for food. It has also been found that insects can carry parasites that are harmful, even deadly for human consumption. However, the fact that the use of pesticides in producing edible insects is largely unregulated can’t be ignored, and so using insects as a food source does carry associated risks. But these demerits can be eliminated by using advanced technologies in a much cleaner and safe farm by inbreeding the insects in a controlled environment.

Notable Breakthrough Start-Ups

Notable three breakthrough start-ups in insect protein used in the food and beverage industry utilizing distinct types of insects are listed below for reducing the carbon footprint on the planet and moving toward sustainability, protection, and regeneration of biological systems.

All Things Bugs (Headquarter- Oklahoma, US)

- This start-up has a cricket powder Griopro which can be used as the base ingredient in food items at the most affordable wholesale price starting at USD 35 per pound.

- Griopro is the finest, lightest color cricket powder in the market with a mild aroma that can be used in applications such as protein shakes, pasta, and baked goods where smooth texture, light color, mild flavor, and aroma are critical attributes.

- All Things Bugs has become the largest supplier of cricket powder in the US and are delivering to other food providers like Exo and Chapul.

All Things Bugs was founded in 2011 and has raised USD 3.5 million in funding from the Bill and Melinda Gates Foundation, the US Department of Agriculture, and the mysterious US defense research institute DARPA to research insect protein and insect farming. Cricket farming is outsourced to farms in the US, and farmers are required to provide a wheat-free diet to the crickets so the end product is gluten-free. Processing of the insects is done with patented proprietary technology, and the resulting powder is a high protein ingredient that can be used in all kinds of recipes.

Hargol FoodTech (Headquarter- Tel Aviv, Israel)

- Hargol FoodTech is using inbred grasshoppers to make gummies in different flavors like orange and strawberry.

- The firm farms its locusts at an indoor, solar-powered facility in northern Israel. The main species that it breeds is the migratory locust, along with the desert locust, and a bush cricket called nsenene.

- They can breed 400 million locusts a year in their facilities and the insect takes just 29 days to become fully grown.

Hargol FoodTech claims that compared with beef production, locust farming reduces greenhouse gas emissions by 99%, water consumption by 1,000 times, and arable land usage 1,500-fold. Mr. Tamir, CEO has also highlighted that their locusts are both kosher and halal with 72% protein content, all essential amino acids, and no saturated fat or cholesterol. The firm is about to introduce a range of products like energy bars, burgers, and falafel balls.

Entoprotech (Headquarter- Caesaria, Israel)

- Entoprotech is a circular economy company engaged in organic/food waste treatment and processing.

- They are harnessing Black Soldier Fly-BSF (Hermetia illucens) to convert food waste into a variety of advanced products.

- Entoprotech has R&D activity in Israel and Russia and a production facility processing 15 tons of organic waste daily.

Entoprotech is a hands-on player in the food industry, large-scale farming, and protein production. They use the best of Israeli tech-developed in-house advanced technology in clean-tech and agri-tech in genetics, biochemistry, and animal feed fields. The basic principle behind the concept is that BSF larvae are ferocious eaters of organic materials and convert organic waste double of their weight into high-quality protein and fat. Among the anti-microbial products are defatted insect meal which can be high protein replacement of fishmeal, high-quality insect fat as oil that is currently used as feed and has many potential uses in cosmetics and pharma, frass (leftovers of larvae metabolic activity) which is high-quality organic fertilizer.

Agriprotein (Headquarter- Cape Town, South Africa)

- AgriProtein is technically based in the UK through a holding company, although its main farm is based in Cape Town, South Africa.

- The company uses Black Soldier Fly (BSF) and their larvae to convert organic food waste into fishmeal for fish, poultry, pigs, and pet food and focus on aquaculture.

- Their products include MagMeal, an alternative protein for use in livestock and aquaculture feed, natural oil for use in animal feed, and MagSoil, an organic soil enhancer.

The start-up was founded in 2008 and has raised USD 122.5 million in disclosed funding, including a USD 105 million round in June 2018. The factory in South Africa can convert up to 100 tons of food waste per day from food factories, supermarkets, farms, and restaurants, producing about 2,000 tonnes of its MagMeal protein per year, along with a residual soil conditioner called MagSoil.

Protix (Headquarter- The Netherlands)

- Protix Biosystems are harnessing Black Soldier Fly-BSF (Hermetia illucens) for chicken feed and aquaculture, creating branded insect-fed chicken eggs and insect-fed salmon.

- The start-up is pushing hard into the insect-based pet food market.

- They utilize lipid extraction technology to produce ProteinX.

ProteinX is one of the main ingredients in a new premium dog food in the UK. ProteinX is produced from a patented lipid extraction technology that does not require any artificial solvents nor uses techniques that may create heat- or pressure damage to the desired characteristics. The nutritional bandwidth of ProteinX remains within a narrow range, even in the case of fluctuating insect feedstock. It’s also developing a new wet pet food based on insect protein called PureeX that is supposed to be good for gut health.

References

8 min read

8 min read