The Curious Case of Semiconductor Chip Shortage for the Auto industry

Listen to this Article

mins | This voice is AI generated.

mins | This voice is AI generated.

The whole world is experiencing the worst chip shortage in decades. Semiconductor chips, are used in everything from smartphones, smart fridges, computers, and automobiles. A few companies that are responsible for chip manufacturing have been facing a severe shortage of silicon material supplies. This article will throw light on the chip shortage issue, explain why it has happened, how it impacts the automotive industry in particular, and where it will lead us.

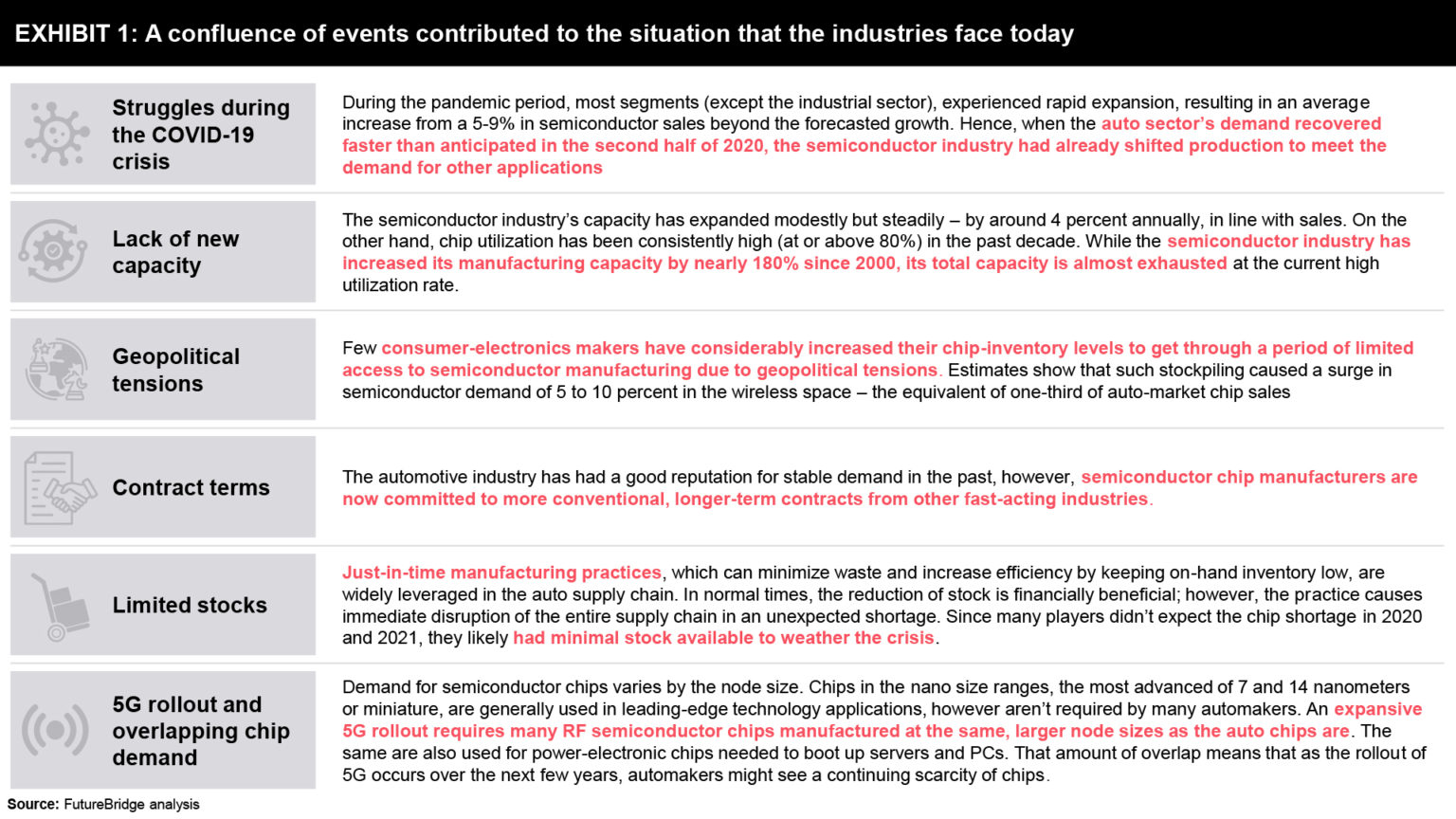

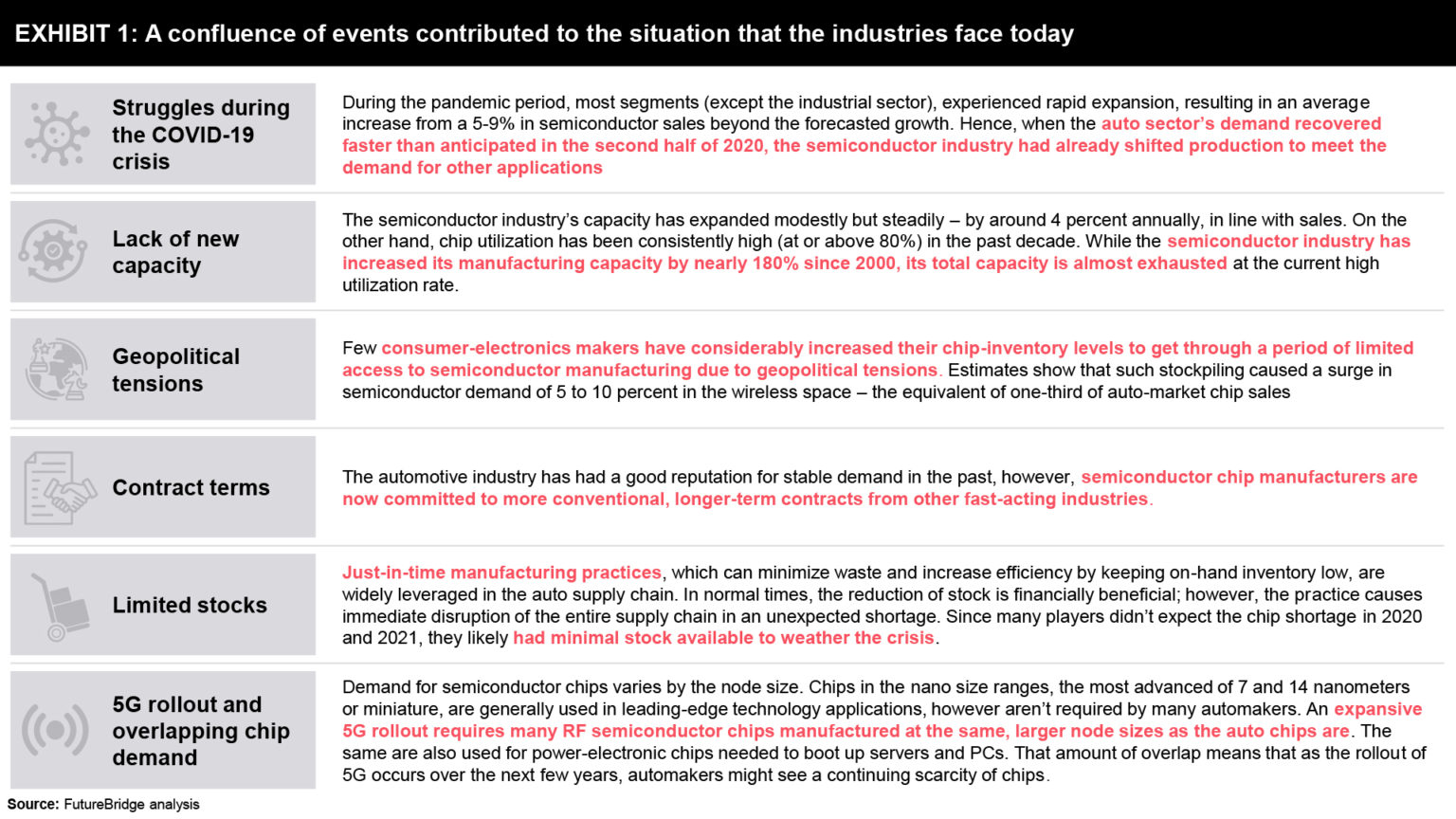

Until the end of the last year, the chip shortage was hardly discussed. Only in 2021, the chip shortage continues to increase. The COVID-19 pandemic was the beginning of all supply-related challenges. Coupled with an increase in demand, it has created a shortage impacting many industries. Multiple events triggered these consequences. Exhibit 1 below presents diverse reasons that led to this chip shortage crisis.

Many industries were negatively affected by the chip shortage as chips are the essential elements of every electronic device.

Among them, the automotive industry was one of the most severely impacted. It all began when the automotive companies miscalculated the vehicle demand due to the COVID-19 pandemic early last year. According to reports, the gap between vehicle production and their sales in 2020 was around 2-3 million units, indicating several million supply shortages. The chip shortage was the primary reason behind the supply-demand gap and the vehicle delivery delays that it caused.

Global carmakers, in addition to a delay in vehicle deliveries, have reportedly started discarding features and high-end electronic capabilities temporarily to manage the chip shortage they are facing today. For instance –

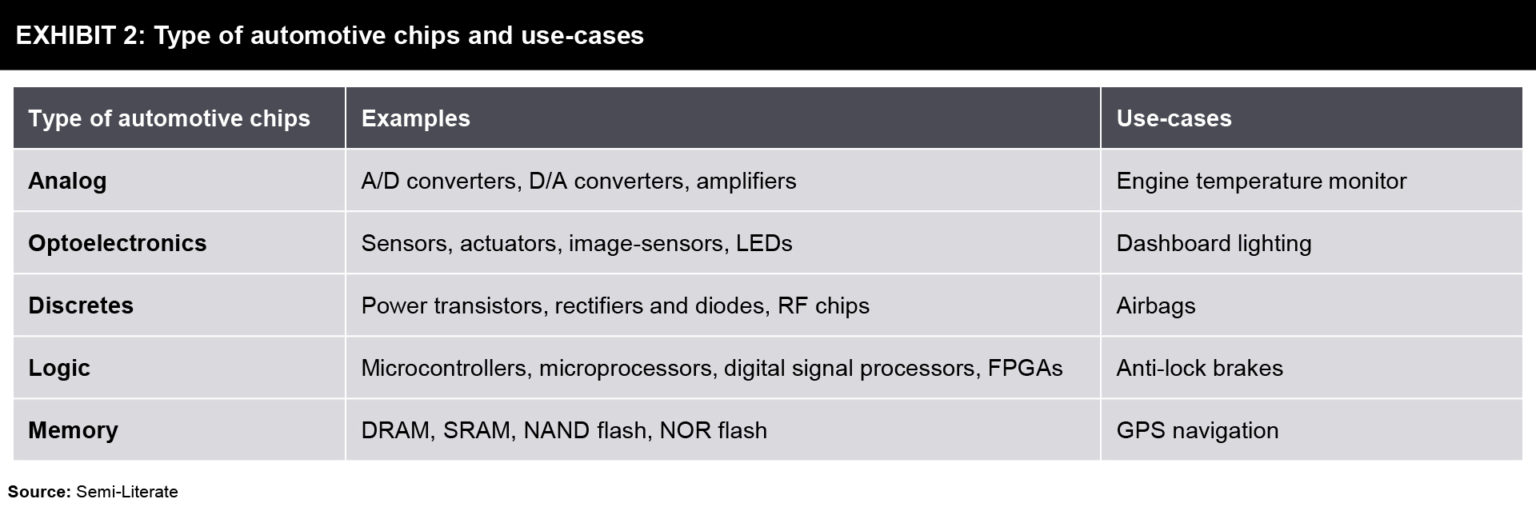

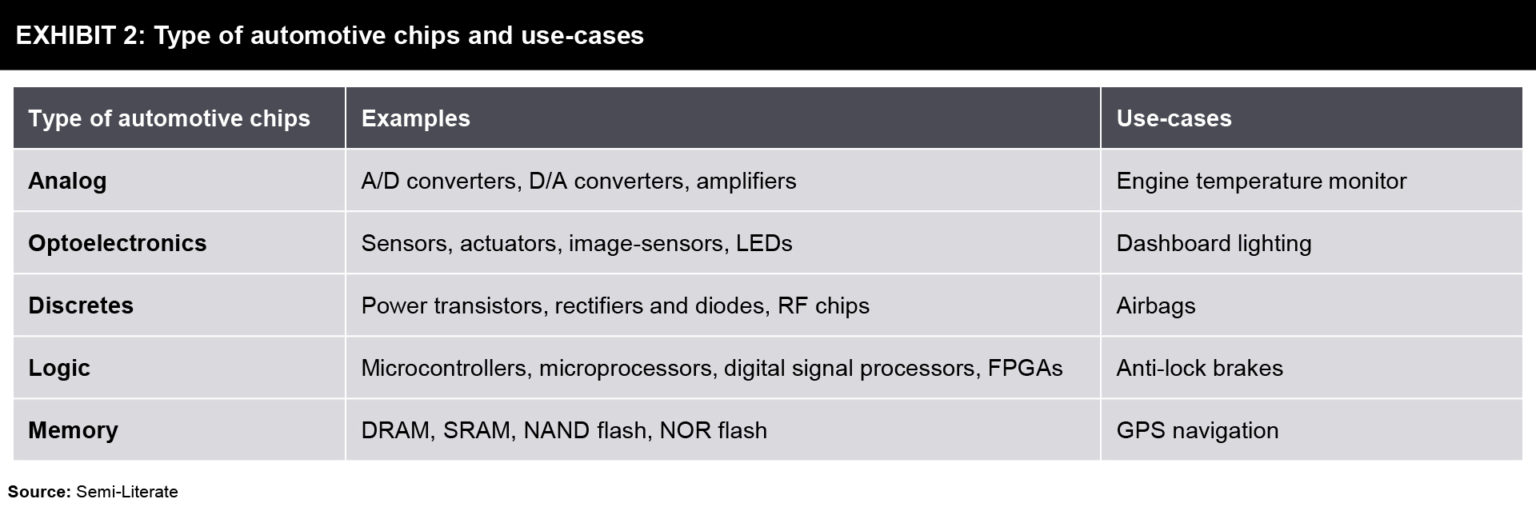

Exhibit 2 below shows the type of automotive chips and their corresponding use-cases that were impacted the most.

Across the value chain, the current chip shortage has disrupted auto businesses as OEMs and suppliers rush to procure reliable chip sources. As auto players plan their next steps, and semiconductor manufacturers struggle to keep up with the demand, both need to align their short- and long-term strategies to manage the supply-chain disruption. Exhibit 3 below presents some short-term, immediate interventions that the auto industry explored, while the industry looking to work around future alternative measures.

However, unfortunately, there is no indication yet that the current supply and demand imbalance for semiconductors will resolve in the short term. Mainly owing to the following key reasons –

The global chip shortage is very likely to extend until the end of this year. However, in the long run, things are expected to improve significantly. Exhibit 4 below presents few strategies that can help automakers solve the long-term problem.

Among global carmakers, Ford said in a conference call to announce Q1 earnings on the 28th of April that it’s likely to lose about half its Q2 production due to the chip shortage it faces.

“Numerous estimates forecast the full recovery of the auto chip supply will stretch into the Q4 of this financial year, and possibly even into 2022. Making industry volume recovery in the H2 of this year even more challenging“, said Jim Farley, Ford president, and CEO.

Chuck Robbins, the CEO of Cisco, had said, “The providers are building more capacity. And things are surely expected to improve over the next 12 to 18 months.”

As it looks at this point, for the automotive industry, the darkest night has finally passed, and dawn is appearing.

References

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur long-standing clients include some of the worlds leading brands and forward-thinking corporations.