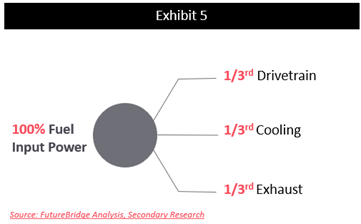

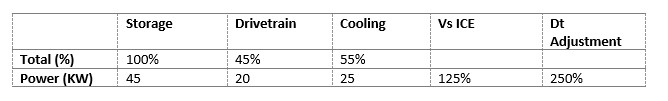

Even if it is assumed that boost function is used for a constant speed, still nearly twice as much cooling compared to the ICE car would be needed.

Effective strategies to optimize cooling and boost FCEV performance

- Increasing the operating temperature of energy cells

Los Alamos researchers created a new polymer electrolyte for high-temperature fuel cells, combining phosphonated polymer and perfluorosulfonic acid. It achieved 60% higher power density than phosphoric acid cells, solving overheating issues in medium and heavy-duty applications like trucks and buses.

- Choosing effective designs like microchannel heat exchangers, plate- and- frame heat exchangers, and helical heat exchangers

- ZeroAvia developed advanced hydrogen-electric aircraft tech, including a pressurized HTPEM system and innovative coatings for aluminum bipolar plates.

- Alfa Laval created ALFANOVA, an all-stainless steel plate heat exchanger for demanding gas-to-liquid operations, using patented ALFAFUSION technology.

- Researchers are also exploring 3D printing to create more efficient and sustainable heat exchangers with complex geometries such as fins and microchannel, potentially outperforming traditional manufacturing methods.

- Optimizing the inflow rates and distribution, like control strategies similar as model- based control to optimize the inflow rate and inflow distribution.

South Korean researchers optimized heat exchangers using genetic algorithms, reducing size and weight while improving performance. They considered vehicle driving cycles for dynamic analysis. Separately, a joint study by Northumbria and Huazhong Universities developed a comprehensive hybrid vehicle model, including a 30kW PEMFC stack. They successfully maintained stack temperature at 350K under real driving conditions, with constant lower inlet cooling water temperature (340K) improving control.

- Using advanced materials with better thermal conductivity, such as ceramics or composites, to create heat exchangers with higher thermal conductivity and lower thermal expansion.

Researchers explored methods to enhance heat dissipation in PEMFC thermal management systems. They tested three nanofluids—Al2O3, SiO2, and ZnO—as cooling media due to their high electrical and thermal conductivity. All nanofluids improved heat transfer capacity, with Al2O3 nanofluid showing the best overall performance, addressing the high heat issue in PEMFC operation.

- Using advanced cooling ways like liquid cooling or phase- change cooling.

A new thermal management system for fuel cell vehicles addresses heat overload issues caused by increasing fuel cell stack power. The system uses a heat-peak controller—a thermal accumulator filled with phase-change material—that interacts with both coolant and air conditioning refrigerant. It temporarily stores excess heat during peak periods, then transfers it to the refrigerant for removal via the condenser when the peak subsides.

- Limiting the maximum power: Limiting fuel cell vehicle power to around 150kW eliminates the need for oversized radiators. This power threshold allows for adequate cooling using standard-sized radiators, avoiding the drag penalties associated with larger cooling systems required for higher power outputs.

Recent Updates

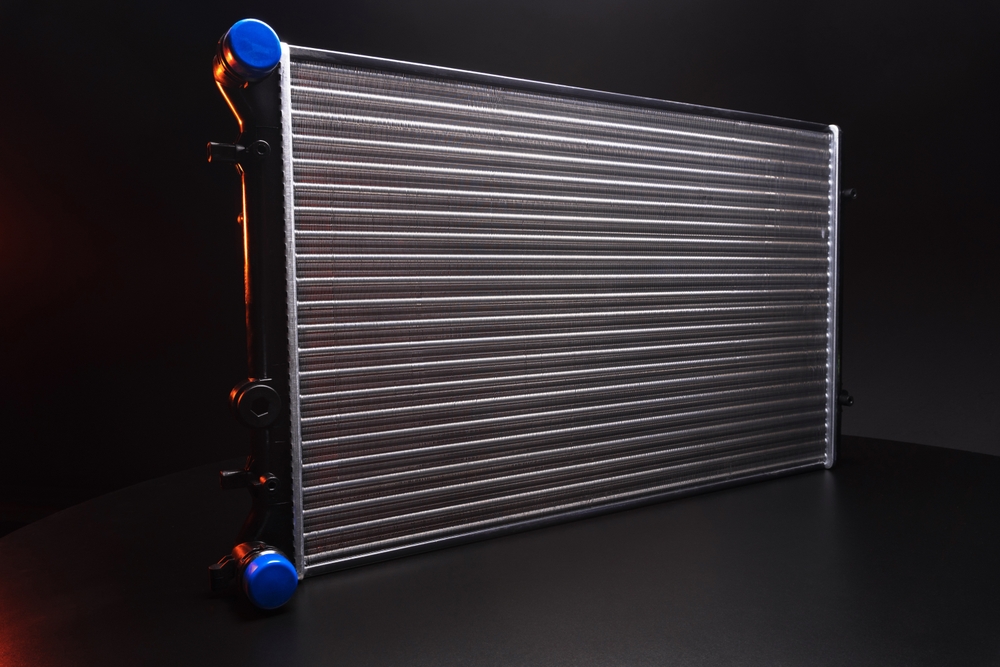

Advancements in thermal management for fuel cell electric vehicles (FCEVs) are driving improvements in efficiency, durability, and overall performance. For instance, Daniel Murphy’s recent project explored ways to enhance the efficiency and reduce emissions of Proton Exchange Membrane Fuel Cells (PEM FC) in heavy-duty electric vehicles, focusing on developing a ruggedized thermal management system (TMS) with a compact, high-temperature radiator designed for low ΔT operation.

Meanwhile, Prof. Prakash C. Ghosh and Nadiya Philip from IIT Bombay introduced a novel method for optimizing the weight and size of FCEV components, boosting vehicle efficiency and accelerating commercialization.

The patent landscape in FCEV thermal management is also rapidly evolving, with China, the USA, and Germany leading in 2024. Notably, Daimler’s February 2024 patent (DE102022132851B3) details a method for estimating the thermal output of a vehicle’s cooling system based on current driving conditions and environmental factors. Additionally, Robert Bosch’s January 2024 patent (DE102022207195A1) addresses load reduction during high-temperature operation, implementing gradual load reduction to prevent excessive wear on fuel cells by managing cooling more effectively.

Conclusion and Futuristic Perspectives

As of now the thermal management system poses various challenges that need to be addressed to ensure safe and efficient operation. These include:

- Heat Management

- Cold Start

- Durability

- Reliability

- The most prominent one – the Size and weight of the Radiator.

Adopting advanced strategies can address thermal management challenges in FCEVs. The push for next-generation vehicles—hybrids, plug-in hybrids, FCEVs, and BEVs—continues to spur innovation in this area. Innovators are exploring thermal management techniques for fuel cell plug-in hybrids in low-temperature environments. Advances in battery thermal management, such as hydrogen storage in metal hydrides, show promise for fuel cell hybrids.

Innovative thermal management solutions will be crucial for new powertrains, especially in long-haul heavy-duty vehicles. Ongoing research into EV thermal management is expected to yield new insights and strategies applicable to FCEVs.

Our foresight finds the future of thermal management in FCEVs promising, with significant potential for improvement across its efficiency, performance, and sustainability. By addressing the existing challenges and capitalizing on emerging technologies, the industry can pave the way for the widespread adoption of FCEVs.

Engage with our experts for guidance on cutting-edge thermal management solutions in FCEVs, driving efficiency, performance, and sustainability in next-gen vehicles.