Digitalization to Accelerate across Automotive Value Chain

Global uncertainties, especially price wars, and COVID-19 pandemic are resulting in new operational and technological challenges as well as potential opportunities for the automotive sector. Automotive players have been adopting digital technologies across their processes from product design, procurement, production, supply chain, all the way to sales and marketing.

Several automotive companies have steadily enhanced their digital capabilities through re-organization, creation of digitalization business units and task forces while many others are partnering, acquiring and forming joint ventures to create a more resilient business

Some examples of increasing usage of digitalization & data analytics in the automotive industry include –

BMW’s plant in Munich, Germany, is increasing the use of artificial intelligence (AI) in applications to integrate into the various production processes combined with smart data analytics for enhanced efficiency in vehicle production. Artificial intelligence helps to identify recurring patterns in the production process, based on the data collected in real-time, to support continuous optimization, and to gain a clearer picture of the entire manufacturing process.

Mercedes-Benz partnered with a start-up Circulor for using blockchain to track emissions of climate-relevant gases and the amount of secondary material across the supply chain of battery cell manufacturers.

Mercedes-Benz partnered with a start-up Circulor for using blockchain to track emissions of climate-relevant gases and the amount of secondary material across the supply chain of battery cell manufacturers.

Cisco and Oxbotica, a global autonomous vehicle software company partnered to demonstrate an open roaming platform that can enable the seamless and secure sharing of high-volume data by autonomous fleets while on the move in a cost-effective way.

Cisco and Oxbotica, a global autonomous vehicle software company partnered to demonstrate an open roaming platform that can enable the seamless and secure sharing of high-volume data by autonomous fleets while on the move in a cost-effective way.

Similarly, most industries are following the same trends with a strong focus on digital and data-driven operations to underpin successful collaboration between suppliers, OEMs & customers exchanging data and enhancing supply planning capabilities.

Serendipitously, the digital transformation of the automotive industry is also synchronized with other seismic changes like electrification, autonomous driving, and shared mobility. The legacy players, to some extent, have been shocked by the speed with which electrification became relevant, and other trends are not so different in adoption as well.

At the same time, many new players who are driving these changes come from digital technologies background and are not only driving the mobility specific change but are also very easily leading in adoption & innovative usage of digital technologies in other aspects of the business beyond the product itself.

Key Drivers and Challenges for Digitalization

Some of the key drivers for digitalization of the automotive ecosystem include –

Increasing pressure on costs and quality

Existing cost structures in the supply chain are limiting the potential cost savings. Hence, automotive manufacturers are moving to just-in-time (JIT) operations that may contain costs and improve supply chain operations. The digitalization of the supply chain will not only improve operational efficiency but also increase traceability and transparency in operations.

Further, errors in manual quality control and quality assurance along with the transfer of data among systems impact the quality of products as well as associated costs. Implementing digital solutions such as predictive maintenance, monitoring would reduce production downtime and optimize operations.

Developing products complying to environmental regulations

There is increased pressure from regulators across the globe to make transportation safe & sustainable, particularly to combat pollution, congestion, climate change, and passenger & pedestrian safety.

Many of these challenges are tackled by developing solutions that are connected and smart. For example rapid increase in usage of digital technologies like

- Connected, cooperative vehicles

- Perception sensors, digital processing of sensor data, machine learning

- Monitoring & predictive technologies for vehicle systems to ensure optimal operation

The regulators have also pushed for such initiatives slowly. Globally, there are several programs and initiatives to develop concepts like smart cities and intelligent transportation systems by digitalizing and connecting the infrastructure. There are also proposals to mandate adoption of technologies like automated emergency braking, glare-free headlamp, etc. which have a more significant digital requirement – pushing suppliers to develop their digital capabilities.

Sustainability and creating a transparent ecosystem

The ever increasing global need of industries to be more sustainable and responsible is also driving the digitalization of supply chains. A good example of this is the supply chain of cobalt for automotive batteries, where manufacturers have started using digital tools to ensure that they are not part of unsustainable and unethical mining practices. Technologies like blockchain and smart contracts will further be adopted to achieve this goal of traceability & transparency.

Product complexity and ever-changing market dynamics

Product cycles are shrinking due to shortening technology cycles and rapidly changing customer needs, requiring real-time agility and visibility across the participants in the entire value chain. New automotive features like passenger monitoring, infotainment, and several other digital & connected services have become the key value driver for automotive players.

The readiness of key technology trends and the adoption of new business models is conducive to digitalization. Some of the key trends contributing to increasing digitalization in the automotive ecosystem include –

Figure 1: Megatrends shaping the digitalization of automotive value chain

Future of Digital Value Chain

The next 2 to 5 years will witness the emergence of clear digital, connected supply chain in the automotive industry. It is imperative for stakeholders across the industry to digitally operate the business by building an intelligent and digital supply chain.

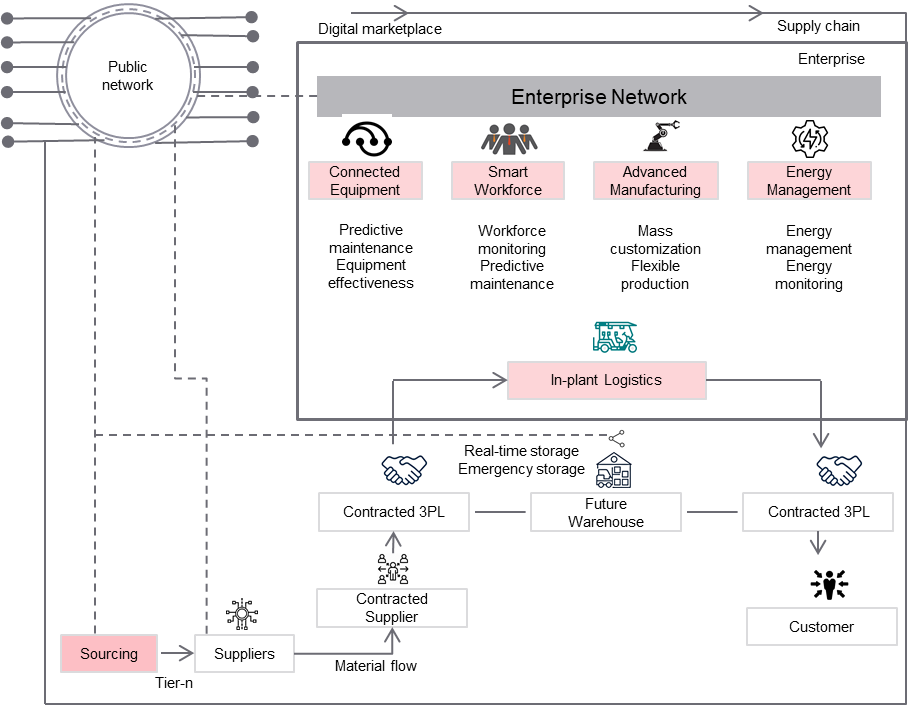

Figure 2: Future of the digital value chain Source: Confederation of Indian Industry

The digital value chain will break down the traditional silos across the ecosystem and enable collaboration to develop more strong and robust businesses that are better prepared to deal with unexpected circumstances. Procurement, logistics, manufacturing, and data management & analytics play a vital role in the digital value chain. In spite of several processes and paper-driven bottlenecks on the back of digital connectivity across stakeholders, warehousing flexibility and intelligence, connected visibility, planning, and ensuring adherence to accurate storage and delivery standards, and emergency response/disaster management will ensure the seamless connection and agility. Strategic tools will remove redundant operational tasks like procurement and make it integral to product development. These also enable stronger QA/QC controls, flexibility, and improved buyer-seller collaboration ecosystem. Manufacturing shop floor with a mix of networked equipment and machines working along with operators will enable real-time data-based efficiency, failure prevention, enhanced capacity management, and flexible production in-plant and across plants.

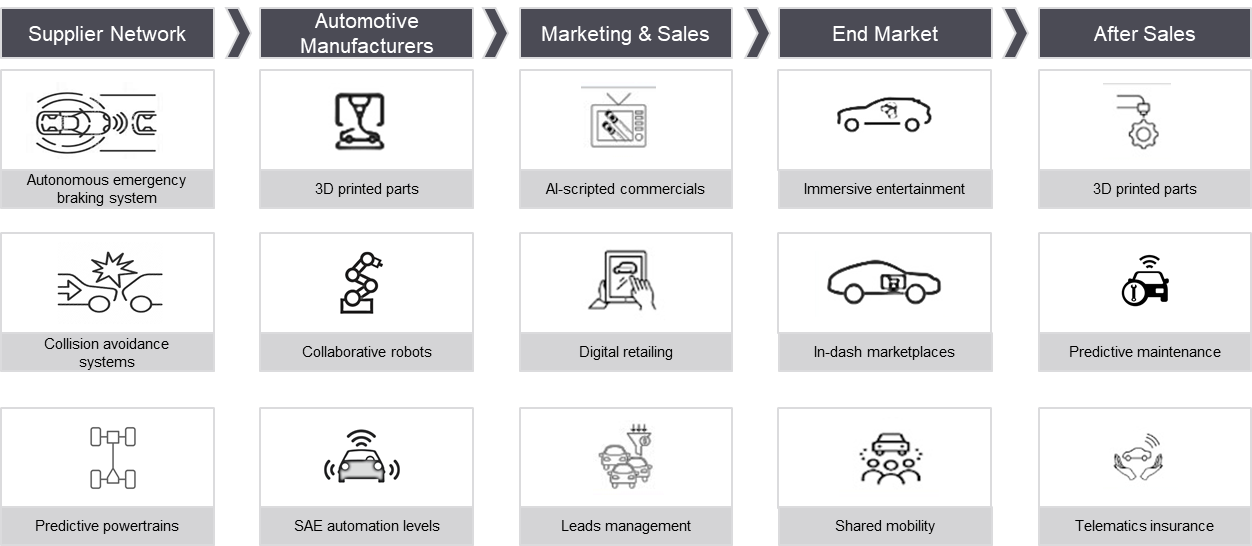

Figure 3: Key digital technologies and solutions in the automotive value chain Source: Robotics and Automation News

Supply chain, including inbound and outbound logistics, plays a crucial part in ensuring continuous production and evolution of new processes and business models in the rapidly changing automotive ecosystem. Data warehousing and intelligence which is an integral function of the supply chain, drive predictive control by focusing on data mining, and analytics. Connected visibility function of the automotive supply chain, enables seamless tracking and tracing of material across in-process and logistics, and facilitates more robust decision making across the value chain. It also allows real-time planning and continuous process, backed by real-time demand sensitivity, control over opportunity cost in the market, and greater visibility across business functions.

Conclusion

The automotive industry is facing a paradigm shift with intelligent and data-driven operations across the business, including, production, supply chain, sales & marketing, and after-sales services. The industry needs to accelerate digital transformation with a clear focus on integrated systems solutions, data management, and analytics to create value from data. There are several technologies, such as automation, advanced robotics, machine vision, IoT, data management & analytics that will enhance operations across the value chain.

Need a thought partner?

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur Clients

Our long-standing clients include some of the worlds leading brands and forward-thinking corporations.

- © 2021 Cheers Interactive (India) Private Limited. All rights reserved. FutureBridge ® is a registered trademark of Cheers Interactive (India) Private Limited.