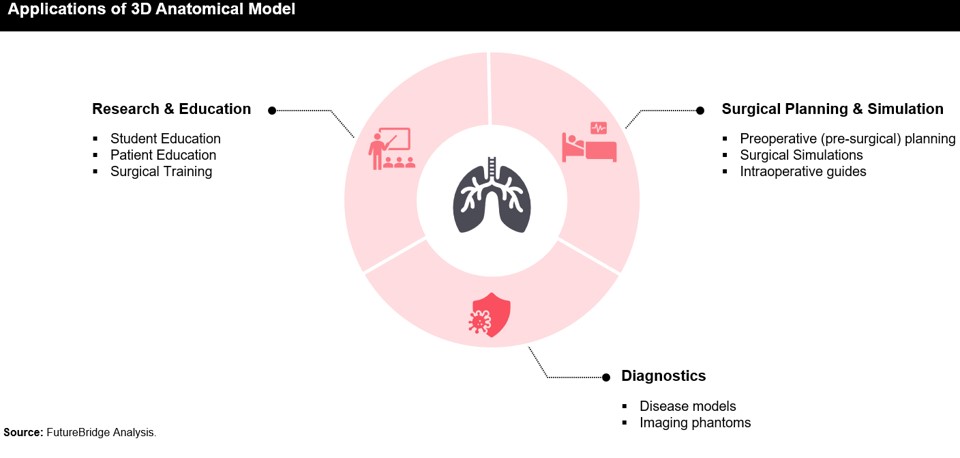

Research and Education:

These include

- Education and Surgical Training

Conventional teaching methods like textbooks, cadavers, and 2D images often struggle to convey the complexities of human anatomy. Enter 3D-printed models: medical students and professionals can now interact with accurate organ replicas, fostering intuitive understanding and enhancing surgical precision. This innovation reduces learning curves, improves proficiency, and slashes healthcare education expenses.

An example of 3D-printed anatomical models in education and surgical training is how the first-year Bachelor of Medicine and Bachelor of Surgery (MBChB) students at the University of Edinburgh utilized 3D-printed anatomical models to learn human anatomy effectively in their education and surgical training.

- Patient Education and Communication

3D printed anatomical models offer a concrete depiction that patients can feel and inspect and thus they are an excellent way for patient education and communication. Medical practitioners can use these models to visually explain patients’ complex diagnoses and treatment approaches.

3D-printed models serve not only as educational tools but also aid in diagnostics, offering comprehensive insights into patient anatomy. These models provide a physical representation enabling multi-perspective viewing, enhancing the interpretation of medical imaging data. Medical professionals leverage these models to design diagnostic interventions, detect irregularities, and assess pathology with greater precision.

Pre-surgical Planning:

3D-printed anatomical models can play a vital role in preoperative assessment and planning as the success of the surgical procedure is highly dependent on the careful preoperative anatomical assessment and appropriate surgical planning by the surgeons. This enables surgeons to determine customized surgical approaches, optimize implant placement, and anticipate possible challenges before initiating the treatment.

Moreover, owing to their several benefits, these models are being used for pre-surgical planning in areas such as cardiac surgery, orthopedic surgery, neurosurgery, and maxillofacial surgery, among others. Surgeons at the University Hospital Southampton are pioneering the use of 3D-printed liver models in treating hilar cholangiocarcinoma, a type of bile duct cancer. This approach exemplifies the practical application of anatomical models in surgical planning, showcasing their potential to revolutionize medical interventions.

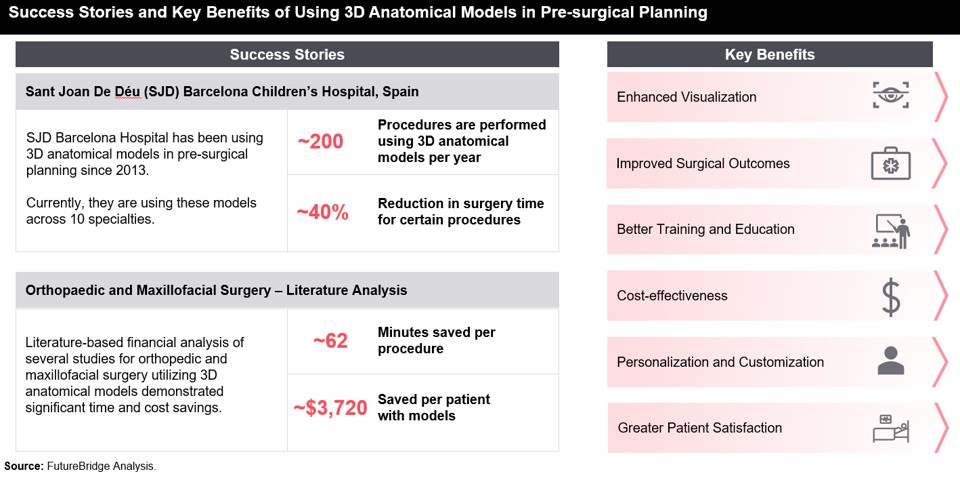

Furthermore, with the technological advancements in 3D printing and imaging technologies, the scope of the 3D printed anatomical models in pre-surgical planning for different diseases will further increase, thereby leading to wider adoption of these models. The following exhibit shows success stories and key benefits of using 3D-printed anatomical models in pre-surgical planning.