What is a Digital twin?

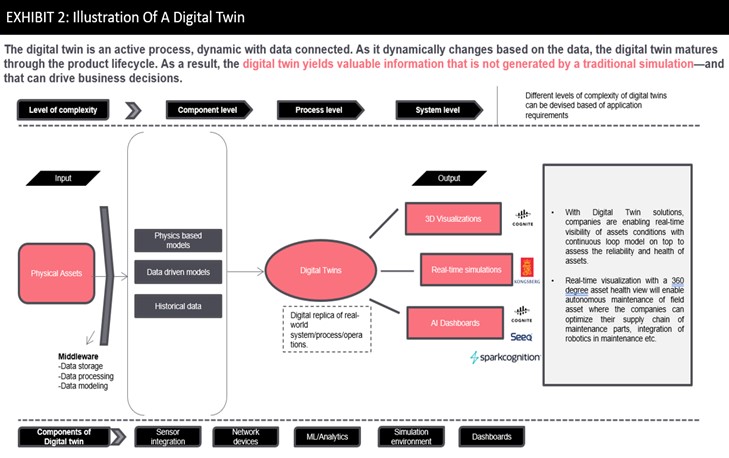

The concept of the digital twin was originally proposed in 2002 by Michael Grieves for use in the field of product life cycle management (PLM) and gaining momentum with advancement in IIoT ecosystem. The phrase “Digital Twin” refers to digital replica of any physical object, entity, process, person, or a system contextualized in a digital version of its environment. It is a virtual model designed to reflect the properties and behaviors of the physical object and its environment. Digital twins enable organizations to model real-world scenarios and their outcomes, enhancing decision-making and increasing confidence in achieving desired business results.

In a bright sunny day, imagine yourself as a COO overseeing your company’s production facility. Suddenly thrust into a high-stakes decision-making scenario demanding extensive research by evening. The time pressure is intense, increasing the risk of errors and uncertainty. Now, envision your organization possessing a Digital Twin of the entire Supply Chain. It autonomously simulates multiple solutions, presenting them on one screen with probability scores based on robust data. All that’s left is for you to select the optimal course of action.

In the business world, certainty is invaluable, and emerging digital twins can provide it. Essentially, a digital twin is a virtual counterpart of a physical entity or process, allowing realistic simulations for a better understanding of real-world behavior. These twins are continuously updated with data from their real counterparts and include behavioral insights and visualizations. When integrated into a single system, digital twins create an Industrial metaverse—an immersive digital environment that replicates and connects all aspects of an organization, optimizing simulations, scenario planning, and decision-making.

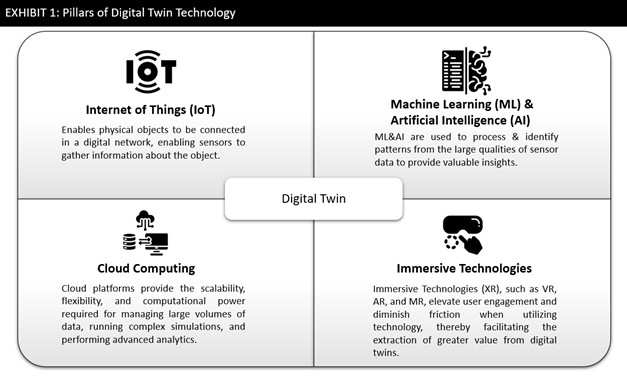

These are the four core technologies upon which the foundation of Digital Twin has been built:

- Internet of Things

- Machine Learning & Artificial Intelligence

- Immersive Technologies (Such as AR, VR)

- Cloud Computing

Types of Digital Twins

There can be multiple types of digital twins. For discussion purposes, let us categorize them. Digital twins can be classified either based on the level of abstraction or according to their intended purpose.

Types of Digital Twins classified based on various levels of abstraction:

- Component Twins: These twins replicate individual components within a system. For crucial components affecting performance, like key engine parts, virtual replication is essential. Additionally, less critical components exposed to constant stress can also have their twins.

- Asset Twins: Asset Twins encompass the synergy of individual components forming a complete asset, such as an engine or pump. They can either draw data from Component Twins or be a combination of them. Asset Twins evaluate how components collaborate, aiding in identifying areas for improvement without physical intervention.

- System Twins: System Twins, or Unit Twins, operate at a higher level, uniting Asset Twins. They enable assessment of how individual assets cooperate within a broader system. For instance, in car manufacturing, a System Twin combines assets necessary for propulsion, electricity, and bodywork. System Twins optimize asset collaboration for maximum performance and efficiency.

- Process Twins: Process Twins represent entire production facilities, offering insights into unit collaboration and timing. This level of complexity reveals how individual units’ synchronization impact efficiency and logistics. Monitoring through digital twins becomes crucial to ensure all components fulfill their roles effectively, making the entire process functional.

Types of Digital Twins categorized based on their intended purpose:

- Product Digital Twins: Digital twins validate product performance virtually and monitor real-world behavior. This ‘product digital twin’ links the virtual and physical realms, enabling analysis, adjustments, and informed decisions, cutting prototype needs, shortening development time, enhancing product quality, and facilitating swift responses to customer input.

- Production Digital Twins: A production digital twin ensures efficient manufacturing by simulating processes and analyzing them through a digital thread. Creating product digital twins for equipment helps prevent downtime and predict maintenance needs. This data-driven approach leads to faster, more efficient, and reliable manufacturing operations.

- Performance Digital Twins: Smart products and plants generate extensive operational data. Performance digital twins gather and analyze this data, enabling companies to seize new opportunities, enhance virtual models, aggregate operational data, boost product and production system efficiency, and facilitating informed decision-making.

Benefits & Advantages

- Improved efficiency: Digital twins can be used to optimize processes and improve efficiency. Further, digital twins save a considerable amount that goes into testing and evaluation of various operation strategies. Since multiple scenarios can be simulated and tested for results, the best productive set-ups can be adopted by organizations with high efficiency.

- For example, a digital twin of a manufacturing plant can be used to simulate different production scenarios and identify bottlenecks, which can then be addressed in the real-world plant.

- Cost savings: As touched upon in the previous point. Multiple operation scenarios can be evaluated in a virtual world and the most productive system can be operated in the real world. It helps in saving costs. Further, for the product twins, the number of real-world products that are used in testing reduce with adoption of digital twins and thus there are enormous cost savings in automobiles, engines, power plants, wind-turbines, etc.,

- By simulating and testing new ideas in a digital twin environment, companies can avoid costly mistakes and reduce the risk of expensive equipment failure.

- Predictive maintenance: Digital twins can be used to monitor equipment in real time and predict when maintenance is needed. This allows companies to schedule maintenance proactively, reducing downtime and increasing productivity.

- Enhanced safety: Digital twins can be used to simulate dangerous scenarios and test safety protocols before they are implemented in the real world. With advancement of AR and VR technology, some dangerous environments, such as nuclear environments, can be simulated and created in a virtual model and analyzed for various conditions. The digital twin offers multiple attempts and allows making mistakes which aren’t possible in a real-world environment where the mistake can lead to a catastrophe.

- Real time data analysis: Digital twins can be used to collect and analyze data from multiple sources in real time, providing valuable insights that can be used to improve processes and increase efficiency.

- Education & Training: Education and training is one of the most impacted domains with digital twin technology. Some high cost and critical operations such as mining, operation of nuclear power plants, offshore applications, wind-turbine maintenance, disaster relief programs, etc., are critical and usually the training cannot be conducted in real world. The jobs are demanding and can make life-and-death difference if not done in proper way. The digital twin technology not only provides a virtual environment with hundreds of scenarios but also allows the users to make mistakes and take their time in adapting to various situations. These onboardings make the learnings much more engaging and ensure high safety in real world operations.

Challenges And Key Considerations While Adopting Digital Twins

-

While the benefits of digital twin technology are clear, implementing a digital twin strategy requires careful planning and execution. Here are some key considerations:

- Data quality: Digital twins rely on high-quality data from sensors and other sources to be effective. Businesses must ensure that their data is accurate, reliable, and up-to-date, and that they have the right systems and processes in place to collect, store, and analyze it.

- Integration: Digital twins require the integration of multiple systems and technologies, including sensors, data analytics, and machine learning algorithms. Businesses must ensure that these systems are compatible and that they can work together seamlessly.

- Skills and expertise: Implementing a digital twin strategy requires a range of skills and expertise, including data science, engineering, and software development. Businesses must ensure that they have the right people and resources in place to develop and maintain their digital twins.

- Security and privacy: Digital twins are vulnerable to cyber-attacks and data breaches, so businesses must ensure that they have robust security and privacy measures in place to protect their data and systems.

Data gathering & communication is rapidly expanding with new developments happening every moment. Moreover, the steady rollout of 5g systems is improving connectivity, and in a short time, the accessibility of data would dramatically increase. Industrial manufacturers are using these opportunities to digitally transform their operations, quality inspections, process and product management systems. This has led to large scale adoption of digital twin technologies in the past year. More and more organizations are now exploring how they can utilize digital twins for better efficiency and productivity.

The operation monitoring and performance management for these industries are being disrupted by new processes that are influenced by digital twins and simulations. The ability to gather data in real time is evolving and technology is becoming more and more cost effective. It would create more openness for the digital twin technology in the industry. Currently, a lot of companies that are implementing IoT are already using digital twins in their operations. Evidently having a profound impact on manufacturing and business, we can expect this trend to continue well into another decade.

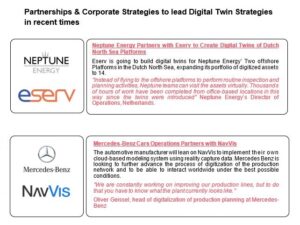

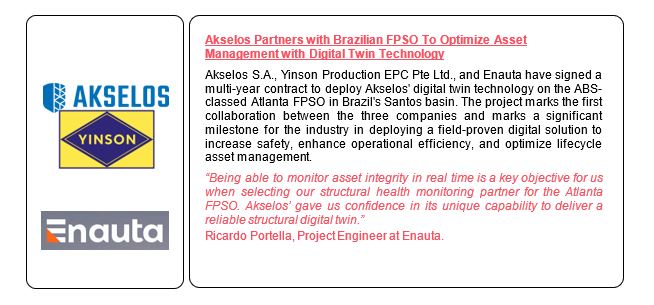

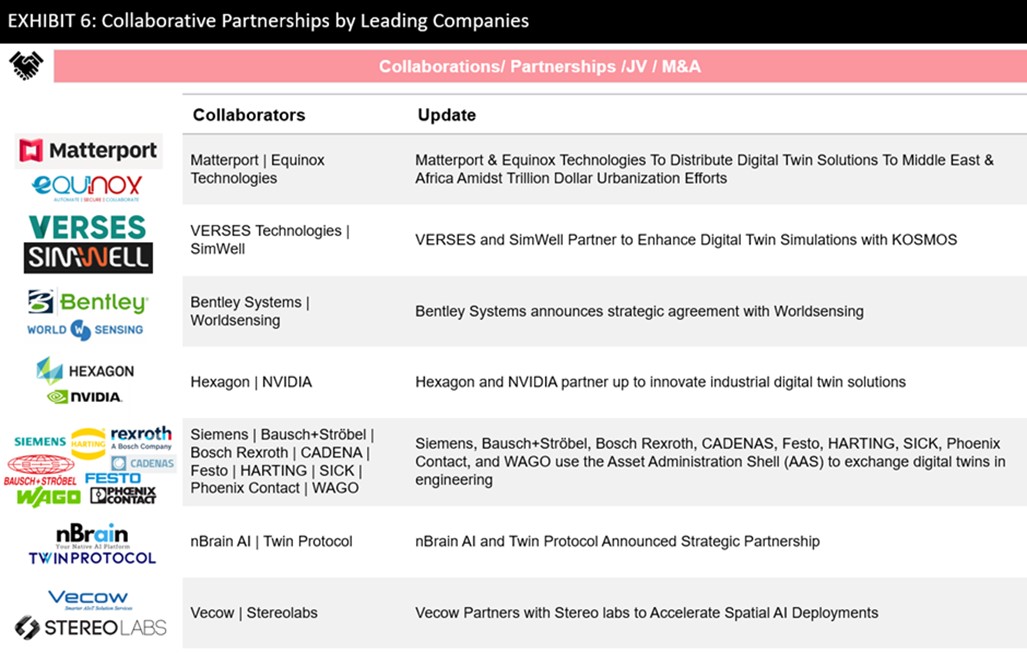

Though the current trend clearly indicates adoption is favored by larger firms, the smaller firms would also start utilizing the technology in future for gaining efficiencies and improving their productivity. This would be led by partnerships, subscription models and easy IT hardware rental-services. Since a lot of the firms won’t have access to skilled engineers, there would be a new demand for third-party businesses that would create and manage the digital-twins technology for these firms. Subscription services and new kinds of sales which rely on rentals and long-term financing plans are expected to rise. The Industrial manufacturing industry is expected to see multiple partnerships with technology savvy firms in the next 5-6 years.

The technology of digital twins would be impacted by generative AI and machine learning. Both these technologies would help the engineers and operators to analyze the data swiftly and come up with new process management plans. The existing tasks of identifying the bottlenecks, maintaining records and predicting future performance would be taken up by the AI systems and that would help the skilled workers to quickly identify the most suited operational models. The edge computation, cloud computing and data availability from various locations would further boost the accuracy of the digital twin simulations. However, the large amount of data would also create a need for high quality hardware and more processing power. Thus, the digital twin supplier companies would opt for collaboration with IT asset intensive firms who are leading with development of IT hardware.

The hardware for Virtual reality and Augmented reality systems are also expected to be cost-effective in coming times. It would revolutionize the technology adoption for training and education purposes and boost the digital twin adoption in newer applications. The existing applications where the usage is still focused on production, quality assessment and monitoring. We expect the future applications would shift to include the entire value chain of the product/process development on digital twins.

Digital twin technology has been slowly evolving over the years and the recent advancements in the communications systems, sensing hardware, capabilities of large-scale data processing, and low-cost availability of various hardware needed for digital twins would increase the adoption of digital twin technologies in various Industrial automation practices.

Due to the large number of benefits offered by the digital twin technologies, more and more businesses would adopt digital twins and it would generate demand for the players who develop, enable, and consult the right use cases of digital twin technologies.

The rise in adoption of digital twins would also force firms to select, rank, and prioritize certain processes/ applications over others for adopting digitization for a smooth transition. Only the organizations with a well-crafted digitization strategy would benefit financially. Other organizations without a well-crafted strategy of digitization would suffer in adoption and could see short term resistance with various stakeholders.

The success of digital twins’ strategy for organizations would also depend on selecting suppliers who have demonstrated success with similar use cases, are financially reasonable, have access to the futuristic technologies, can provide multiple cost-effective subscription models.

Have queries, contact here for help:

- Should you digitize your business? Is it worth going digital?

- What should be your digitization strategy to stay ahead of competition?

- Who could be your suppliers?

- What technologies you should be adopting?

Need a thought partner?

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur Clients

Our long-standing clients include some of the worlds leading brands and forward-thinking corporations.

- © 2021 Cheers Interactive (India) Private Limited. All rights reserved. FutureBridge ® is a registered trademark of Cheers Interactive (India) Private Limited.