Introduction

Packaging plays a significant role in food and non-food product categories as it provides protection to the goods stored in it. It also serves as a marketing material that attracts consumer’s attention and acts as a communication instrument between businesses and end consumers, thus promoting the product.

Five major functions of an ideal packaging are mentioned as follow:

- Protection: Packaging provides protection to the food product by securing it through tamper-proof designs. It also offers a hygienic environment for the product by securing it in a safe and admissible atmosphere, thus restricting the contamination of food particles. Packaging also protects food or non-food products from biological, chemical, and distribution damages. The main objective of packaging is to protect the contents from deterioration during storage, transportation, and distribution.

- Identification: Packaging plays an important role in helping consumers identify the product and its contents. The labeling in packaging carries the product name, description, and other parameters that help consumers identify products. Labeling and packaging also help in promoting the product and acts as a marketing instrument.

- Communication: Packaging helps in communicating important information about the product, such as its contents, ingredients, nutritional values, cooking instructions, allergic warnings, and expiry dates, etc. It increases the confidence of consumers regarding the genuineness of the product, thus enhancing its saleability.

- Convenience: Packaging also plays a vital role in providing convenience to consumers. For instance, packaging cartons for milk and juice consist of an easy-to-open and easy-to-pour cap that allows consumers to handle the product content easily. With changing lifestyles, the need for convenience in handling products has also increased. For instance, change in eating styles, such as ready-to-eat meals and microwaveable ready meals, are propelling brand owners/product manufacturers to try innovation in packaging materials. Indirectly, this type of packaging also increases the consumption of the product.

- Marketing: First impression has a lot of significance in consumer marketing. Packaging is the first thing that consumers see, and thus, it is imperative to attract consumers in the first instance. Moreover, with increasing competition, manufacturers are continuously improvising their packaging to set their products apart from the rest. Good packaging also adds to the perceived value of the product.

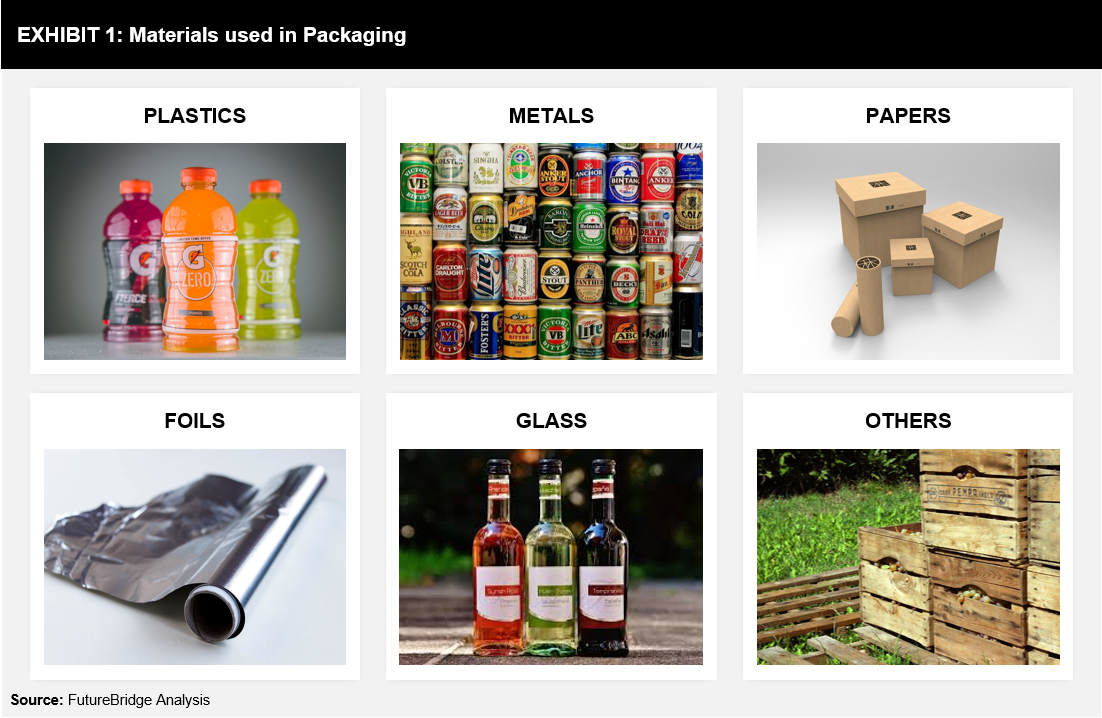

Materials Currently Used in Packaging

Currently, plastics, glass, metals, papers, and foils are key materials used in packaging (refer to Exhibit 1). Plastics constitute almost half of all materials used in the packaging industry, which emphasizes a strong need to implement circular economy initiatives in this industry.

Glass is the most trusted packaging material that has nearly zero rate of chemical interactions. Any product inside the glass package is considered safe for health, as the contents of the product retain their strength, aroma, and flavor. It is one of the widely used packaging materials, which has been granted the FDA status of “GRAS” (generally recognized as safe) by the US Food and Drug Administration. The most important benefit of glass packaging is that it is 100% recyclable and can be reused endlessly with no loss in quality or purity.

Metal packaging is generally made from aluminum or steel and has a very high recycling rate. The generic expression of metal packaging is termed as canning, and canned products have become an important part of the current lifestyle. The recycling of metal packaging is very simple and highly efficient, as there is no loss of quality or quantity during the re-melting process. It is estimated that approximately 98 billion units of metal cans are produced every year in Europe and around 4 units are consumed every week by citizens in this region.

Paper-based packaging, such as container boards, paper boards, paper bags, shipping sacks, etc., is a versatile and cost-effective method of protecting, preserving, and transporting several products or goods. The major advantage of paper packaging is that paper packaging materials are eco-friendly and easily recyclable.

Foil-based packaging is generally preferred for multi-layered packaging, especially in the food & beverage industry. Foil packaging can withstand hot and cold food conditions and maintain product hygiene by preventing viruses and bacteria from contaminating the food. Other materials used in packaging are wood, foam, etc., which are used mainly in tertiary packaging.

All the above-mentioned materials, except plastics, can conveniently be recycled to get the same material of desired properties. Bio-plastics are the perfect choice to replace petrochemical plastics as they degrade with time when left outside, after their respective use.

Sustainable Packaging – the Need, Criteria, and Benefits

Packaging materials constitute about 65% of the global solid waste. Approximately 380 million tons of plastics are produced every year across the globe as of 2018, and a total of about 6.3 billion tons of plastics have been produced over the last 68 years. Of the 6.3 billion tons of plastic, only an estimated 9% has been recycled, 12% has been incinerated, and the remaining is stranded as pollution, contaminating both land and oceans. This huge amount of plastic invariably impacts the environment (both land and ocean), affecting each and every life form. This implies the imminent need for sustainable packaging to save the environment. Sustainable packaging, as a term is a culture or way of development and use of packaging materials. It can be achieved by diligently following the four pointers given below:

- Innovative materials (bio-degradable packaging, compostable, plant-based, etc.)

- Packaging design advancements

- Improvements in distribution and use-phase period

- Improvements in end-of-life processing

Plastics, Worst Offender – Sustainable Packaging is the Solution

Plastics such as Polyvinyl Chloride (PVC), Polypropylene (PP), Polyethylene Terephthalate (PET), Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), etc., are not bio-degradable and stay for a longer duration without decomposing. Several industries, including food & beverage, pharmaceutical, textile, etc., rely on plastics. For instance, pharmaceutical companies primarily use PVC and Polyvinylidene Chloride (PVDC) as primary packaging materials to protect their products against oxygen and odor permeation, moisture, and water vapor transmission, and microbial attack.

Unfortunately, PVC is the worst offender, as it is the least recyclable type of all plastics. PP, PET, HDPE, and LDPE are some other plastics used in the pharmaceutical industry, which contributes to the plastic waste on the Earth’s surface. Plastics account for almost half of the materials used in the packaging industry.

It is estimated that approximately 8.8 million metric tons of plastic waste enters the ocean from coastal communities each year, and about 80% of the plastics to the ocean comes from land sources, including river, sewage, landfills, shipping, fishing, etc. Overall, there are about 236 million metric tons of small plastic fragments floating on the surface of the ocean. Without any action, the amount of plastics in the ocean is expected to rise to 1kg of plastics for every 3kg of fish, and by 2050, there will be more plastics in the ocean than fish. It is estimated that around €170 billion is lost annually due to poor ocean management practices of which, the fisheries sector is estimated to have a loss of around €45 billion.

Criteria to achieve Sustainable Packaging

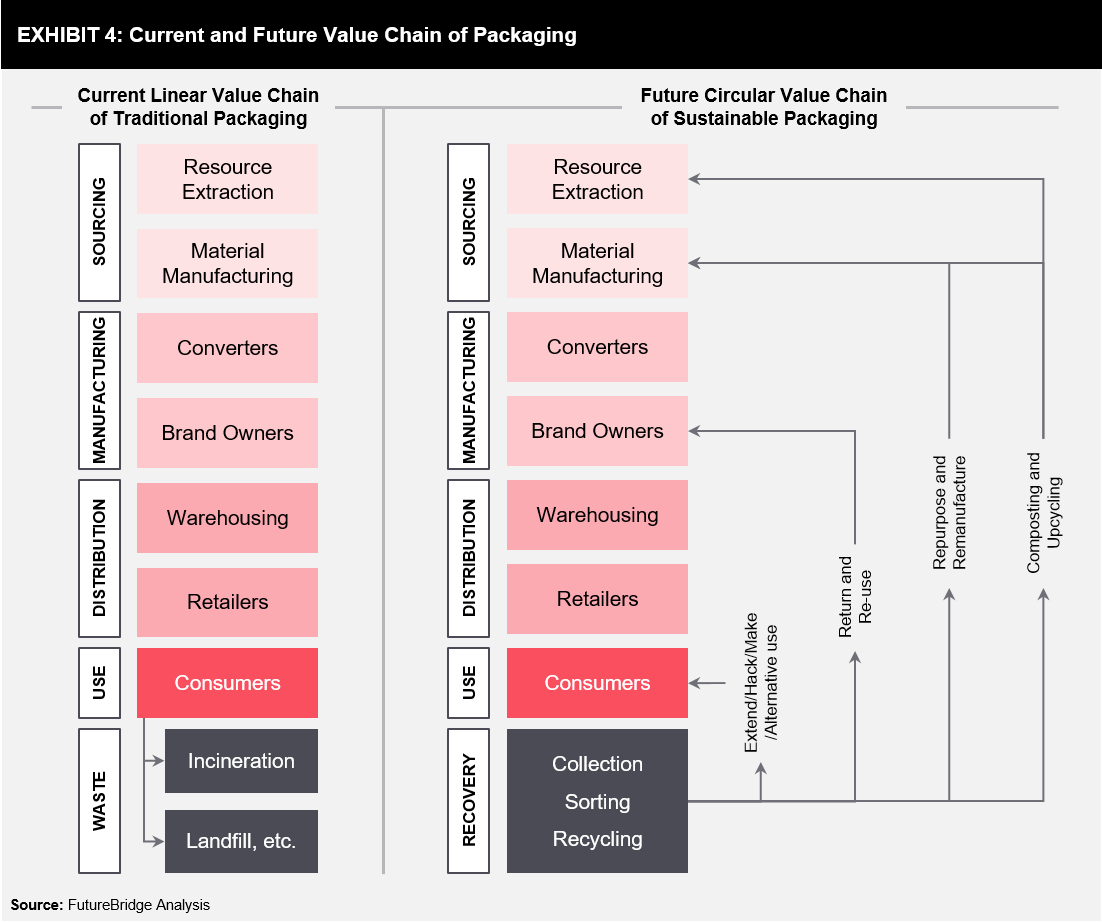

The successful implementation of sustainable packaging involves a perfect blend of business objectives/considerations with environmental concerns throughout the lifecycle of packaging. Activities in the value chain of packaging require transformation, innovation, and optimization, with a circular value chain model. Major criteria that help in the transformation of normal packaging to sustainable packaging that is economically robust throughout its lifecycle are listed below.

- The package should remain safe, beneficial, and healthy for individuals and communities throughout its lifecycle.

- It should fulfill the desired objectives with respect to both performance and cost.

- It should be sourced, manufactured, transported, and recycled using renewable energy.

- The packaging should be manufactured using clean production technologies and best practices.

- It should be made of innovative materials that stay healthy throughout their lifecycle.

- It should be physically designed to optimize materials and energy.

- It should effectively be recovered and utilized in biological or industrial closed-loop cycles.

Benefits of Sustainable Packaging

Sustainable packaging is a type of packaging wherein the best practices are followed with respect to materials, their use, and recycling opportunities. Materials involved in packaging are bio-degradable and compostable, replacing plastics in most cases. However, in some cases where plastics cannot be replaced, sustainable packaging focusses on reusing the packaging or recycling the same for extended usage. Some of the major benefits of sustainable packaging are as follows:

- The package remains safe, beneficial, and healthy for individuals and communities throughout its lifecycle.

- It reduces the overall carbon footprint.

- It is easily disposable and bio-degradable.

- The packaging is versatile and flexible.

- Sustainable packaging improves storage space.

- It is free of allergens and toxins and does not contain harmful plastics.

- It reduces the use of resources significantly.

- It positively impacts brand image, thereby increasing sales.

- Sustainable packaging helps in reducing, recycling, and reusing packaging, thus ensuring cost savings.

Enablers for Sustainable Packaging

A healthy collaboration between government bodies and businesses are required to achieve zero plastic packaging waste in the future. These two entities play an essential role in driving the future of sustainable packaging.

Actions Led by Government Bodies

Government bodies worldwide should impose stricter rules and regulations on driving sustainable packaging, leading the way to the future. Some of the areas where government bodies should focus on are:

- Ban on single-use plastics

- Work on revising and improving packaging producer responsibility policies

- Develop and implement Deposit Return Schemes

- Develop and improve facilities for recycling and reprocessing packaging

- Focus on research related to innovative materials used for packaging

Actions Led by Businesses

Businesses play a significant role in developing sustainable packaging materials. They should work on innovating newer sustainable packaging materials and identifying minimal packaging designs to ensure a sustainable future for the packaging industry. Some of the areas where businesses should focus on are:

- Innovation and adoption of sustainable materials for packaging

- Focus on minimal packaging design

- Implementation of standard industry-wide packaging practices for sustainable packaging

- Focus on return collection channel to replenish and recycle packaging containers

- Develop innovative uses for tertiary packaging, post its delivery

Different Ways for Sustainable Packaging and its Use-cases

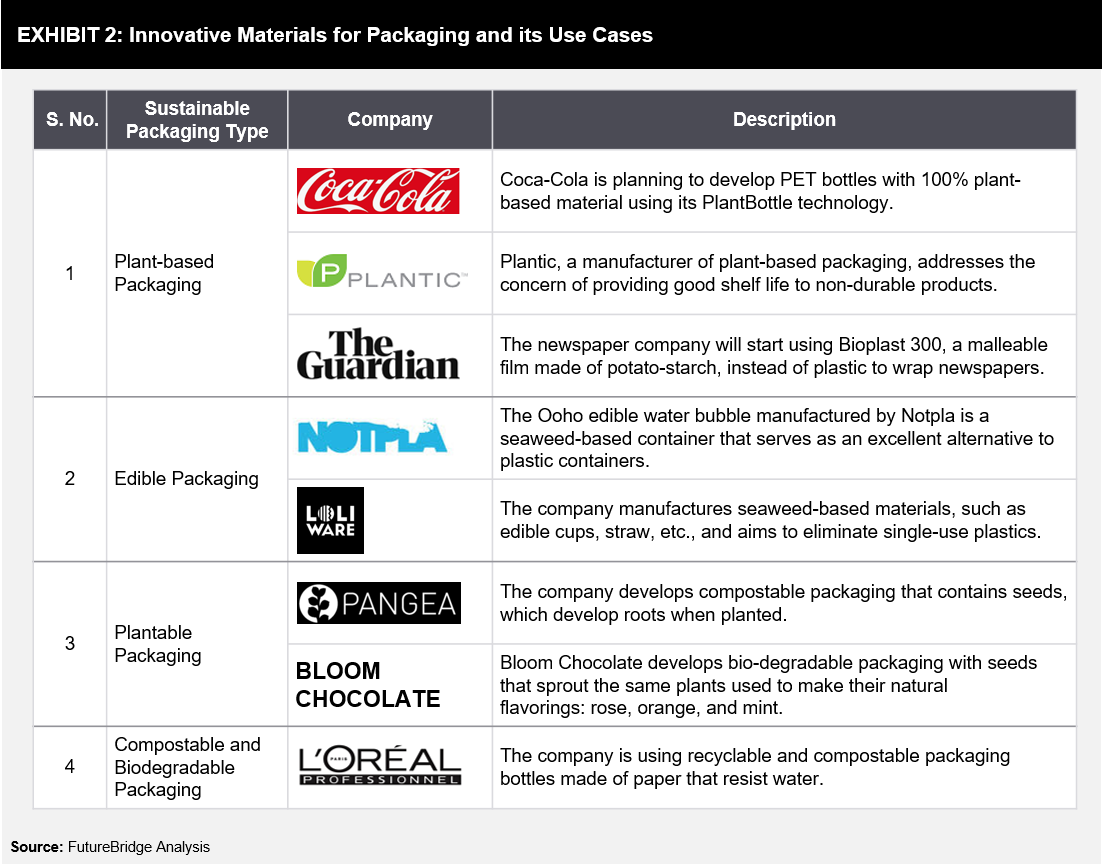

Sustainable packaging is a holistic way of developing, using, and recycling/reusing packaging materials. Besides using innovative material for packaging that bio-degrades and decomposes by itself, manufacturers also need to think of innovative ways to recycle and reuse the packaging material. Some of the major innovations with regards to sustainable packaging have been listed in Exhibits 2 and 3.

Exhibit 2 provides information specific to innovative materials used to achieve sustainable packaging. Packaging ranging from seaweed, paper to plant-based materials that are compostable are used for packaging food products, beauty products, newspapers, etc. Some of the packings are even edible, which, if not eaten, will be decomposed within 4 to 6 weeks.

Exhibit 3 provides information specific to the innovation in packaging design and re-use of packaging materials.

Conclusion: Sustainability is the Road Forward

Sustainability has become an increasing priority in the packaging industry, which consumes a high volume of plastics, especially in the form of single-use plastics. This poses a severe threat to the environment. The industry is responding well to the threat by focusing on innovative materials and designs, as well as return distribution of end-of-life containers.

The amount of garbage produced by people across the globe is increasing rapidly, owing to the change in lifestyle, which facilitates the use of disposable products. The accumulation of in-disposable or non-compostable garbage has led to increased pollution across the globe, especially plastic pollution. This accumulated non-biodegradable garbage poses a severe threat to plants, animals, wildlife, and the human population. This garbage is primarily made of toxic compounds, which are known to cause severe illness. The ill-effects of plastic pollution has already started to affect life in various forms including, groundwater pollution, air pollution, land pollution, GHG emissions, climate change, etc. It is high time to stop using this toxic material and start focusing on sustainable materials to save the environment for future generations.

For the successful implementation of sustainable packaging, manufacturers need to increase their focus on the circular value chain. The current linear value chain of the packaging system will transit to the circular value chain in the future, as depicted in Exhibit 4.

Several players in the packaging industry have already undertaken steps towards the circular value chain of sustainable packaging, and a few of the initiatives taken by well-known players are presented below.

- Coca-Cola is planning to collect and recycle 100% of its packaging globally by 2030.

- Danone, Kellogs, and Pepsico are planning on developing 100% recyclable, reusable, and compostable packaging materials by 2025.

- Mondelez International is planning to develop 100% recyclable packaging materials by providing recycling information for consumers by 2025.

Many organizations are seeking professional help in identifying various options available for them to move away from the current plastic dominated packaging to more eco-friendly packaging materials. With the increasing awareness regarding the damage caused by plastics, consumers are preferring products having eco-friendly packaging materials. Packaging material providers and product companies should take immediate steps toward sustainable packaging or they might be left behind by their competitors.

Need a thought partner?

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur Clients

Our long-standing clients include some of the worlds leading brands and forward-thinking corporations.

- © 2021 Cheers Interactive (India) Private Limited. All rights reserved. FutureBridge ® is a registered trademark of Cheers Interactive (India) Private Limited.