Impact of COVID-19 on food supply chain

A. Introduction to the impact of the current pandemic on the supply chain

The COVID-19 has the highest impact on the food supply chain in almost all regions including North America, Europe, Asia-Pacific, and the Rest of the World. COVID-19 is spreading through the developing world. Developing countries are now reporting growing numbers of cases and imposing rigorous lockdown regulations, which impact all aspects of the economy. All the governments have developed policies to respond to these varied impacts to avoid supply chain disruptions, higher food prices, and severe economic fallout for millions of employees. Asia-Pacific and Europe are the largely impacted region across the globe. This is attributed to most of the cases recorded in the regions especially in the countries including Italy, Spain, Germany, France in Europe, and China, Japan, and South Korea in Asia-Pacific.

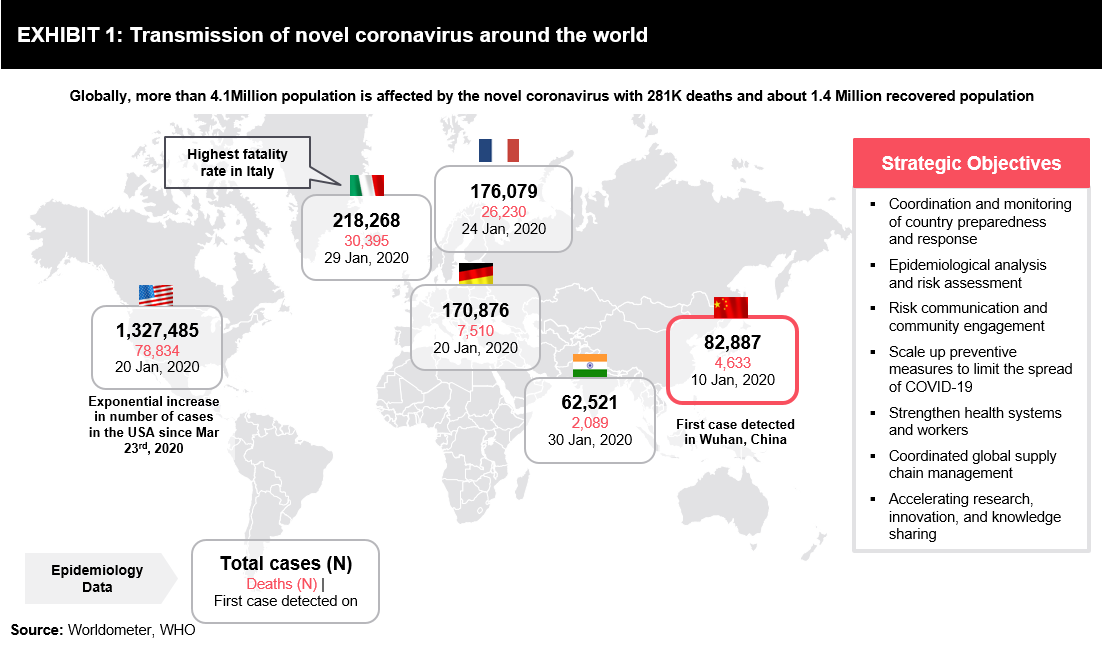

The wake of 2020 has seen an outbreak of a viral flu-like infection caused by a novel coronavirus, which spread rapidly from China’s Wuhan to 215 countries across the world (as of April 6th, 2020). With the sudden outbreak and rapid spread globally, on April 6th, 2020, the World Health Organisation (WHO) global pandemic.

Illustrated in Exhibit 1, as of April 6th, 2020, more than 4.1 million populations are affected by the novel coronavirus.

B. Impact of novel coronavirus on worlds GDP growth

The impact of COVID-19 on different business sectors varies due to the differences in supply and demand patterns. The food industry, already weakened by slow growth rates in 2019, is likely to experience the biggest downturn. This is an unprecedented crisis for unprecedented measures. Many countries are struggling to contain the spread of the Covid-19 epidemic while avoiding a dramatic decline in economic activity. This pandemic is affecting the global economy, hitting the manufacturing and service sectors, with huge impacts on the labor force.

It is estimated that the economic impact of the COVID-19 pandemic will be bad, but its degree remains highly uncertain. The sectors which have the most immediate and high impact will be the services export sector, more specifically, international accommodation services, food-servicing services, and tourism-related services. As many countries have closed their borders, the long-term impact will depend completely on how long the global travel lockdown will be.

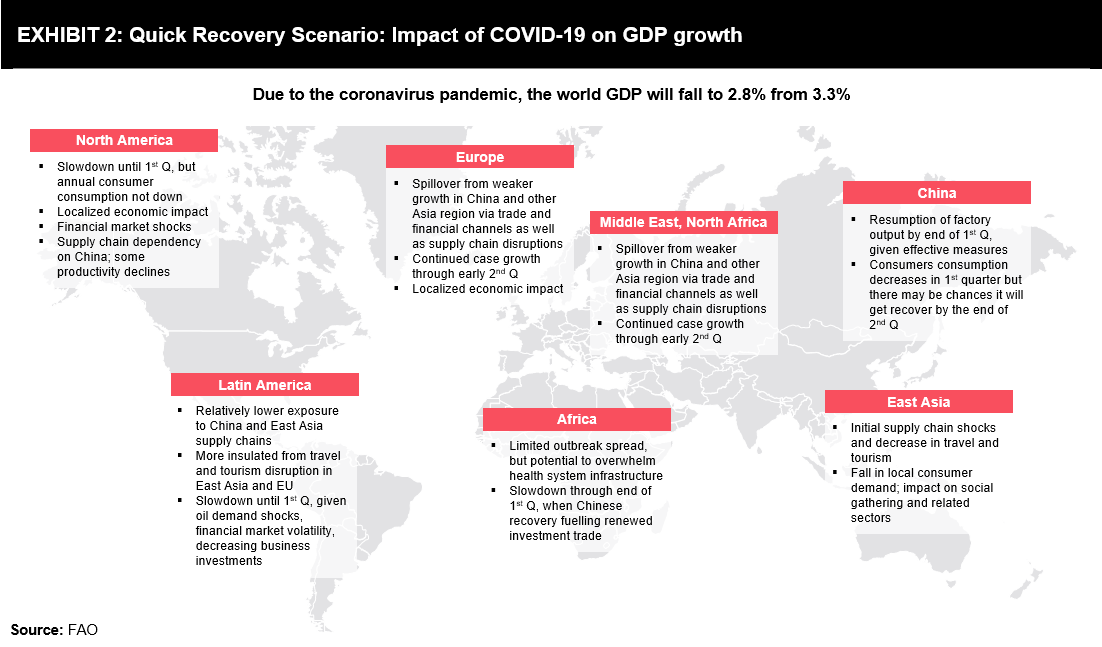

There may be three broad economic scenarios: a quick recovery, a global slowdown, and a pandemic-driven recession.

The quick recovery: Expected 2020 global GDP growth drops from 3.3% to 2.8

Global slowdown scenario: The economy will recover in late Q2, but 2020 GDP growth drops to 1.5%

Global pandemic scenario: In this case, the recession will come, and the growth in 2020 will fall at 0% or below.

In this quick recovery scenario, strong public reaction, and drop in demand, other countries can achieve the same rapid control seen in China. Even in quick recovery scenario regions are having significant economic disruptions.

Exhibit 2, includes the Quick Recovery Scenario model and Impact of COVID-19 on GDP growth across the globe, which shows how GDP growth gets fall due to supply chain disruptions.

C. Impact of COVID-19 on Food manufacturing and supply chain management

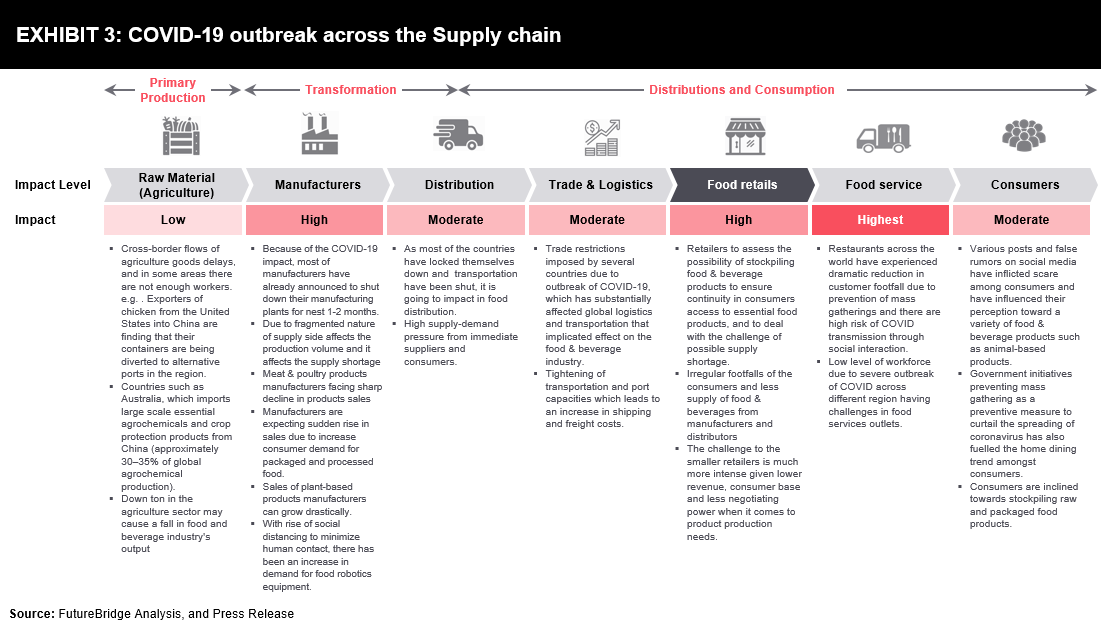

Globally, the food industry is experiencing the differential impact of this rapid spreading COVID-19 on each stage of its supply chain through the mediums of the affected workforce at the industrial level, raw material supply received from agricultural, food ingredients, and intermediate food products, trade & logistics, demand-supply volatility and uncertain consumer demand at foodservice outlets from other factors. Production, distribution, and inventory levels across the food industry are getting impacted.

The people who are affected and working in agricultural farms, food & beverage production & processing plants, and distribution network are now promoting the risk of the outbreak of COVID-19. There is also a risk of spreading the coronavirus through product outputs that increases food safety concerns when a trade occurs between geographies and different stages of the supply chain, which has resulted in a labor shortage. A similar kind of risk is for stakeholders in the industry due to the interaction with potentially affected public, and contact with coronavirus-affected persons. Travel bans imposed by several countries are also a contributing factor, affecting the availability of critical personnel required in crucial decision-making. The workforce can potentially affect business plans and industrial production of food & nutritional products.

Exhibit 3 shows the level of impact of COVID-19 on a different level of the supply chain.

With the rapid spread of COVID-19, the global food industry has been pulled into new and uncertain territory. With this, manufacturers should be prepared and take the right measures on food safety. Due to COVID-19, there may have limited our travel, and on manufacturers, there might be increased economic pressure. Food manufacturers are continuing to follow current good manufacturing practices to ensure the quality and safety of food products by focusing on five key elements: people, premises, processes, products, and procedures. The food manufacturers also have to follow the risk-based food safety plans, such as HACCP.

Nowadays, manufacturing is a complex process, due to the requirements of subcomponents has to assemble a single final product sourced from several places across the region. The raw materials required to manufacture the subcomponents come from different countries and regions, and the final product is then transported worldwide. This dependency upon logistics makes import, manufacturing, and export a difficult proposition in case of disruption to the supply chains.

The world manufacturing sector is getting disrupted due to the following three points.

- Direct supply disruptions are hampering production since the pandemic is focused on the world’s manufacturing area, especially East Asia. It is spreading fast across the other industrial giants such as the US and Germany.

- Supply-chain contamination will strengthen the direct supply shocks as manufacturing sectors in less-affected nations find it harder and it is more expensive to acquire the necessary imported industrial inputs from the more affected regions, and subsequently from each other.

- Consumer demand disruptions due to i) macroeconomic drops in aggregate demand (i.e. recessions); ii) wait-and-see purchase-delays by consumers, and iii) investment-delays by firms.

Exhibit 4 shows the advanced economies that reacted quickly and forcefully when the threat emerged in China in January 2020. It also shows all the largest manufacturing economies in the world (top 10 manufacturing regions) are entering into the recession due to the COVID-19 pandemic.

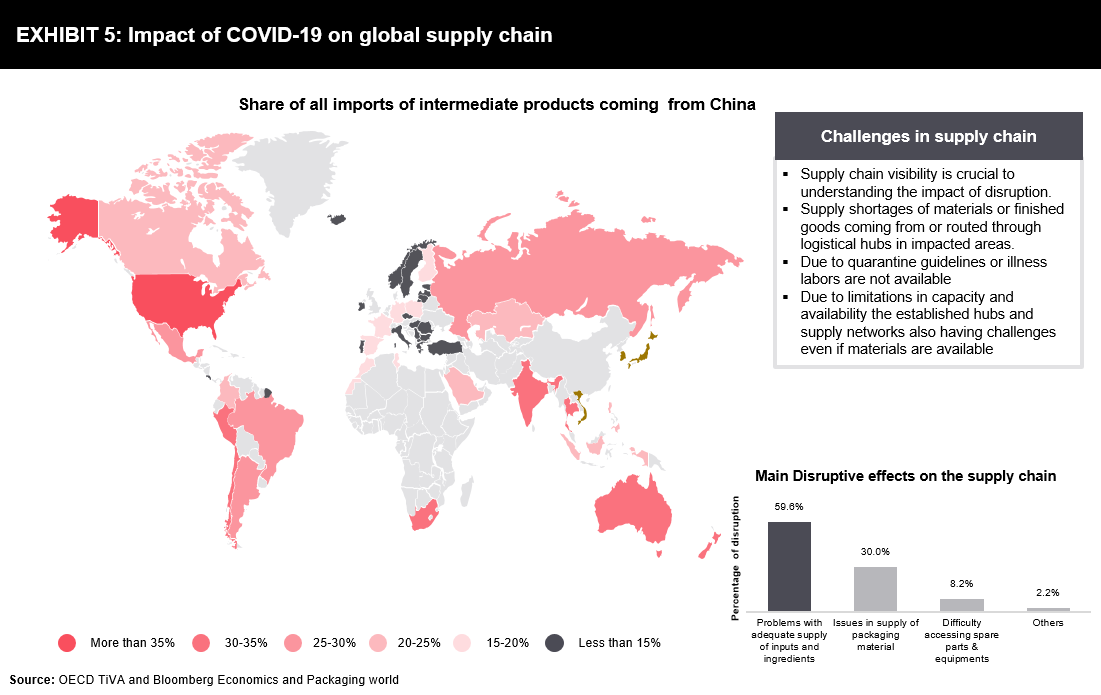

According to a survey conducted by the Institute For Supply Chain Management, nearly 75% of companies have disruptions in their supply chain in one form or the other due to these pandemic related transportation restrictions. Today’s supply chains are incredibly complex, with innumerable partners spread across multiple geographies. Due to the COVID-19 pandemic today, China’s share of global GDP has increased to almost 20%. As recent history has demonstrated, the potential global consequences of a slowdown in China’s economy have increased exponentially.

The Chinese government has shut all the restaurants and cafes in the country. Apart from the food chains, the supply chain has been largely impacted by the pandemic COVID-19, as there is a disruption in the supply chain. For instance, Coca Cola Co. experienced delays in its raw material supply from china as a result of industrial stalls related to the spread of COVID-19 in China. The company sources sucralose from both the US and China; however, it has flagged that Chinese suppliers have experienced delays in production and export.

As shown in Exhibit 5, how the coronavirus infects the supply chain, as China plays a central role in global supply chains.

Reshaping the supply chain

The current crisis is an opportunity to reset a system that has relied on outdated processes. Creating smart and quick supply chains is the key to building a global trade and investment network capable of enduring future storms. The transition to a new model for supply chains will be underpinned by rapid and wholesale digitization of the paperwork that accompanies global trade. From an industrial perspective, the current situation is accelerating digital transformation for businesses across the globe. There is an urgent need to reduce dependency on physical labor across transportation, logistics, and warehousing. This can be done through core digital technologies such as Internet-of-things, blockchain, control towers, artificial intelligence/machine learning-enabled demand forecasting, rule-based and self-adjusting stock allocations, autonomous devices such as AGVs and drones.

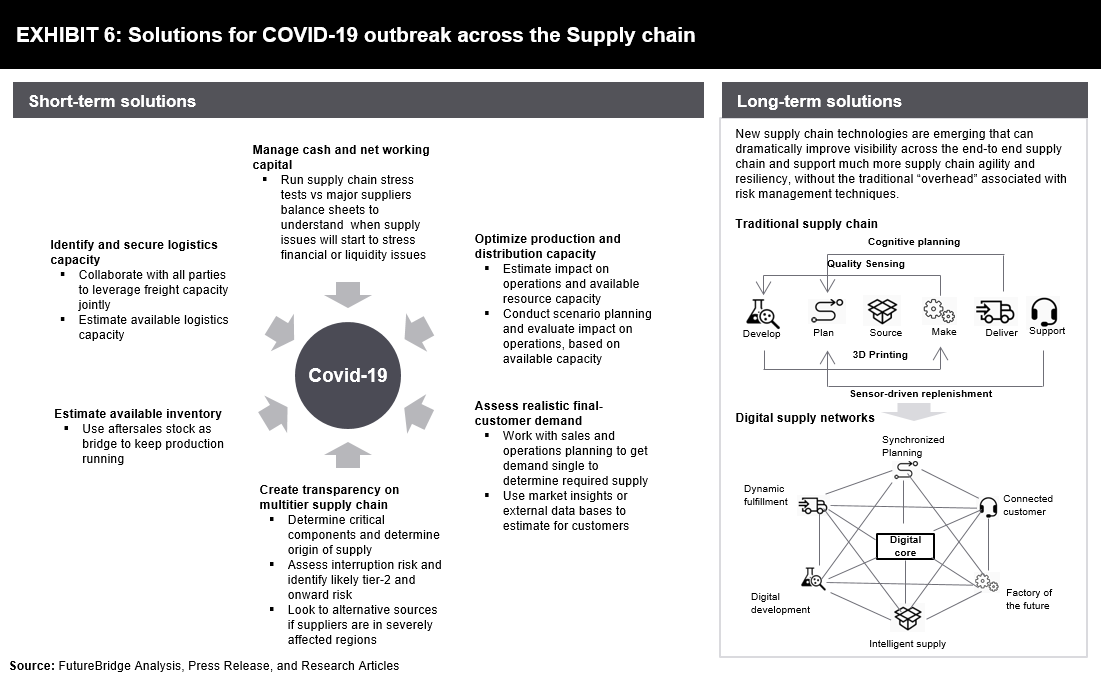

Exhibit 6, shows the short term and long term solution for the end-to-end supply chain action to consider in response to COVID-19.

The new supply chain technologies are emerging that can dramatically improve visibility across the supply chain, and they improve supply chain speed and resilience, without the traditional “overhead” associated with risk management techniques. Therefore to improve the traditional supply chain and to optimize the business, the digital supply networks (DSNs) are required. Hence for that end-to-end visibility, collaboration, responsiveness, agility, and optimization is required. Increasingly, the digital supply networks are being built and designed to anticipate disruptions and reconfigure themselves appropriately to mitigate their respective impacts.

Advances in information and communications technology are making the evolution of the supply chain more possible. Technologies such as The Internet of things (IoT), cloud computing, 5G, artificial intelligence (AI), 3D printing, and robotics are all critical to enabling the digital supply network of the future. At the same time, a volatile business environment is making it all the more necessary. The digital supply network will vary from the industry sector to sector and even company to company.

References

- Worldometer

- Newsletters & Press Release

- Tweets and Social Media

- World Health Organization

- Company Websites

- OECD TiVA and Bloomberg Economics

- Packaging world

- Institute For Supply Chain Management survey

- United nation statistics division

- OECD TiVA data on gross manufacturing production

- FAO

Need a thought partner?

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur Clients

Our long-standing clients include some of the worlds leading brands and forward-thinking corporations.

- © 2021 Cheers Interactive (India) Private Limited. All rights reserved. FutureBridge ® is a registered trademark of Cheers Interactive (India) Private Limited.