Biodegradable packaging, a real alternative in the food & beverage industry

In little more than a century, plastic has gone from being a hero packaging material to one of the world’s greatest environmental problems.

According to the EPA, approximately 70% of plastics in the US are destined to landfill, where they will take from 10 to 1000 years to decompose. By 2050, its projected there will be more plastic in the ocean than fish.

Food and beverage packaging accounts for almost two-thirds of total packaging waste. As consumers become more educated on the impact plastics have on the environment, they’re keen to hold businesses and their packaging standards to account. Companies are now more focused than ever on producing and packaging their products more responsibly.

Biodegradable packaging has appeared as a viable alternative in the industry. Biodegradable packaging materials are naturally derived polymers that are made from various agricultural products such as starch, cellulose, proteins, and plant oils. The biodegradable polymers derived from these sources are mainly renewable and are helpful to maintain a sustainable environment. In order for packaging products or materials to qualify as biodegradable, they must completely break down and decompose into natural elements within a short time after disposal, typically in a year or less.

The main barrier to market uptake is attributed to technical bottlenecks related to the functional and production specificities of bio-based materials that are quite different from petrochemical plastics

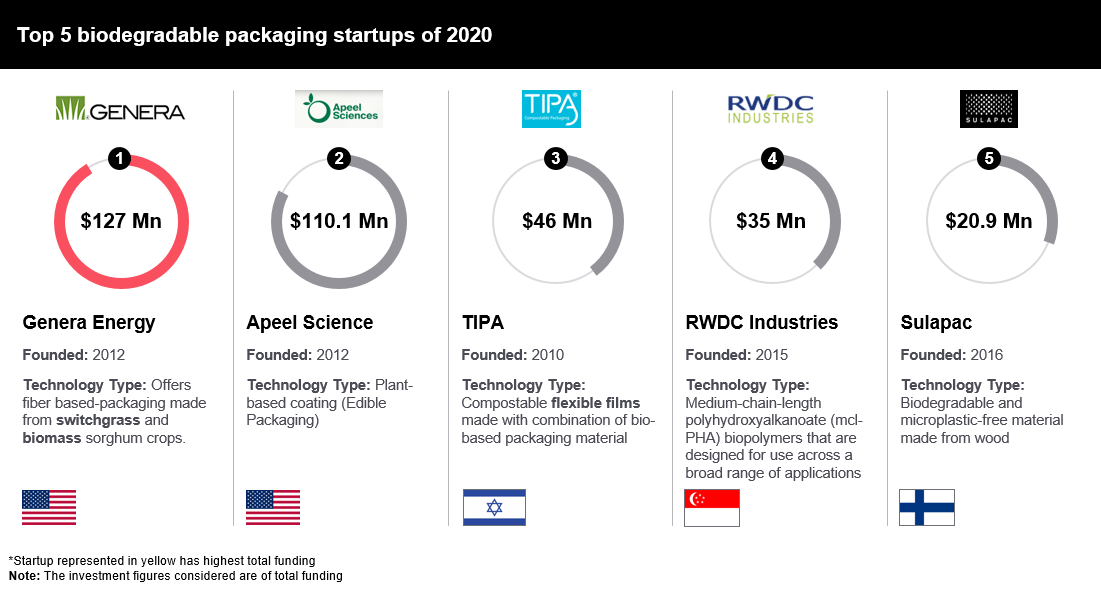

By combining our in-house research and data analytics capabilities with our research team’s deep domain and industry know-how in the food and beverage ecosystem we have identified the top 5 biodegradable packaging start-ups of 2020.

Top 5 start-ups impacting biodegradable packaging industry in 2020

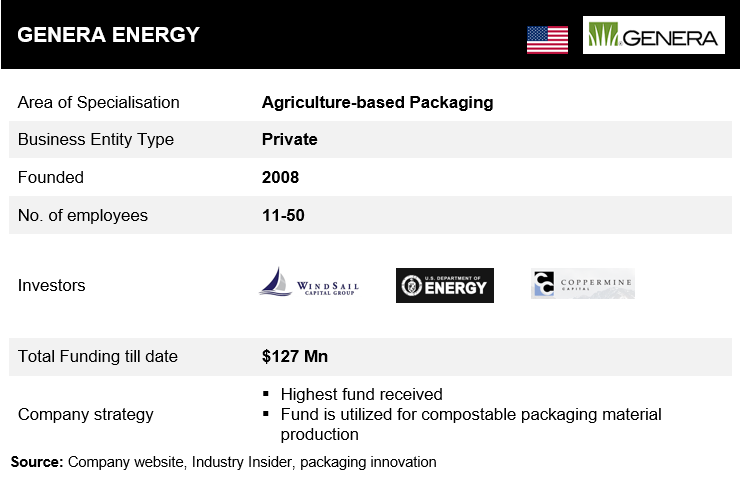

Genera Energy received USD 118 Million funds for compostable packaging line

Genera is a US-based startup that provides an integrated biomass supply solution for the advanced biofuels, biopower, and biobased products industries. Genera operates two key facilities in Vonore and Tennessee. The two facilities are co-located in the Niles Ferry Industrial Park and include the company’s Biomass Innovation Park research campus, which is the company’s fiber products manufacturing facility. Genera has developed sustainable agriculture-based fiber products made from locally grown grasses and crops to make compostable food packaging products.

Genera Energy has received USD 127 million up to 2019 and has recently gained USD 118 million funds. The company has invested its funding in building its first manufacturing facility in Tennessee for compostable food packaging range, Earthable fiber. Additionally, Genera will utilize this funding to produce compostable packaging products includes plates, bowls, and takeout containers at its new manufacturing facility in Vonore, Tennessee.

In the US, due to high consumer demands for eco-friendly products the market for food-grade packaging is growing. Genera Energy plans on expanding its packaging business by partnering with farmers in regions such as Anderson, Blount, Bradley, Loudon, McMinn, Meigs, Monroe, Polk, Rhea, and Roane Counties.

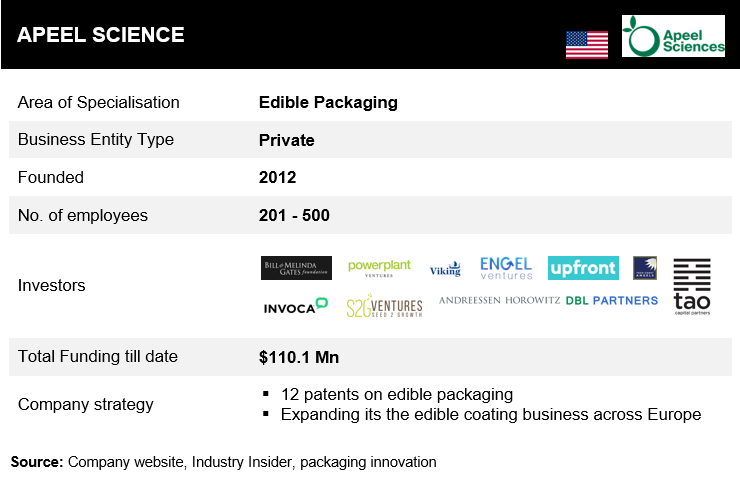

Apeel Sciences develops natural plant extracts to protect fruits and vegetables

Apeel Science was founded in 2012 with a grant from the Bill & Melinda Gates Foundation. Apeel Sciences produce plant-derived solutions to help organic and conventional fresh food providers to improve product quality and reduce food waste. The company works with entities ranging from smallholder farmers, local organic growers to the leading food brands for developing sustainable solutions that enhance the shelf-life of fresh produce. Rather than relying on chemical agents to preserve fresh products, the company has developed a special protective coating to slow down the decomposition.

According to all U.S. Food and Drug Administration regulations, Apeel’s solution is edible and safe to eat. The Apeel Sciences has developed a plant-derived edible coating that has applications in dozens of USDA Organic Certified and conventional produce categories. Apeel’s edible coating is widely used plant-derived materials such as lipids and glycerolipids that are commonly found in foods, which is designated FDA GRAS (Generally Recognized As Safe).

The company has a total of $110.1 million of funding and is backed by Microsoft co-founder Bill Gates and venture capitalist Andressen Horowitz. In July 2018, the company raised $70 million of funding from venture capitalists such as Viking Global Investors, Upfront Ventures, S2G Ventures, and individual investor Andreessen Horowitz as well as other unnamed investors.

Apeel Sciences is expanding its business outside the US with new offices in Mexico, Peru, and The Netherlands. Recently, Nature’s Pride (Netherland) announced it is collaborating with Apeel (US) to launch long-lasting avocados to reduce food waste across Europe. Apeel Sciences has a partner with Edeka, Salling Group, and Houweling’s to expand its business in the biodegradable packaging industry. Apeel has reduced avocado waste up to 50% with the help of its retail partners and the company also has done the partnership with Houweling’s by this partnership, every year it will eliminate 60,000 pounds of plastic shrink wrap from cucumbers. In September 2019, Apeel announced its national expansion with Kroger in more than 1,100 supermarkets across the country. The company has a total of 12 patents published and recently, the company has published its patent on the topic plant extract compositions for forming protective coating in which it presents the disclosure relates to plant extract compositions and methods of isolating plant-derived monomers, oligomers, and mixtures thereof for applications in agricultural coating formulations.

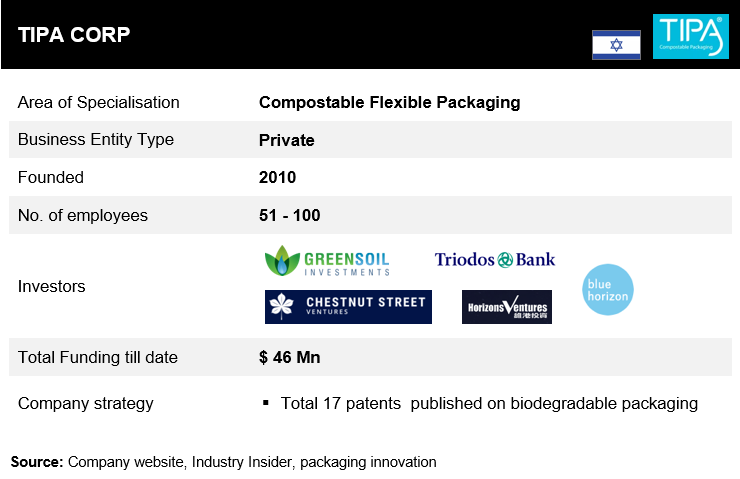

TIPA is on a mission to create a compostable future for flexible packaging

TIPA is an Israel-based startup that manufactures bio-based packaging that provides compostable flexible packaging solutions for the food and fashion industries and is built to fit existing machinery and supply chains. The company provides packaging solutions that have optical properties such as conventional, flexible plastic packaging, including transparency, flexibility, sealing strength, durability, barrier, and shelf life. TIPA compares its packaging material to orange peel, decomposing in 180 days in compost conditions. Its packaging solutions are currently being implemented worldwide by leading global brands in Europe, Australia, and the US. It offers sustainable packaging solutions that break down and return to nature, which is a viable alternative to conventional plastic material for the food industry.

The company has in total USD 46 million funding and has recently secured USD 25 million funding, which will be used to expand its sales in new territories and to further develop its product portfolio. The company produces biodegradable flexible plastics product line that includes ziplock bags, garbage bags, etc. In 2019, the World Economic Forum named TIPA a Technology Pioneer and the company also received the second rank in FoodTech 500. TIPA received the transformational solution award in the category of waste, water, and land at the 2019 Transformational Business Awards. Recently, TIPA is shortlisted for the best sustainable packaging solution provider in World Food Innovation Awards. The company has a total of 17 patents and its patent titled name Biodegradable sheets has received a grand in the US, Australia, and the UK. The patent talks about the invention, which gives the composition for biodegradable sheets comprising at least one hydrophobic polymer, such as polycaprolactone (PCL) and/or a polyhydroxyalkanoates (PHA).

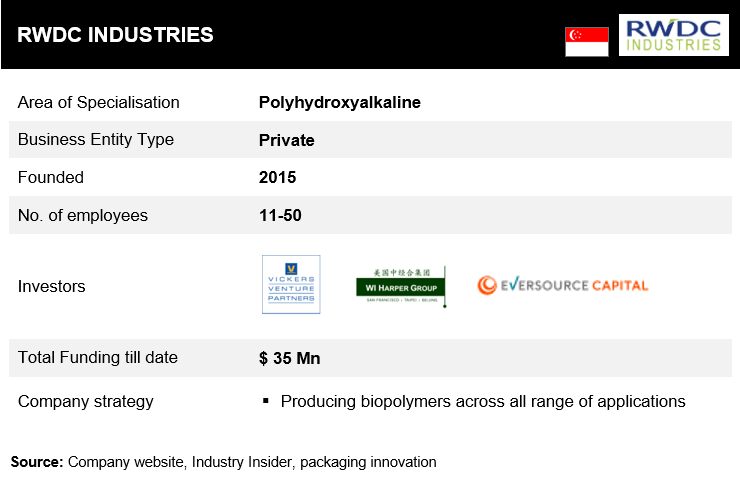

RWDC Industries aims to eliminate single-use plastics with cost-effective biopolymer material solutions

RWDC Industries, a Singapore-based biotech start-up, founded in 2015 by Mr. Roland Wee and Dr. Daniel Carraway. This biotechnology-based company develops innovative and cost-effective biopolymer material solutions. In particular, RWDC produces medium-chain-length polyhydroxyalkanoate (mcl-PHA) biopolymers that are designed for use across a broad range of applications.

RWDC Industries has developed technology to harvest outputs of a microbial fermentation process using plant-based oils that produces a naturally occurring biodegradable polymer called PHA (or polyhydroxylalkanoate). PHA’s are biopolymers naturally produced by microbial fermentation of plant-based oils or sugar. RWDC’s PHA—Solon is certified by TÜV Austria to be fully biodegradable in soil, water, and marine conditions. Solon is fully biodegradable within weeks with no toxic residue.

The company has recently closed Series A funding round, which will be primarily used to increase the production capacity and this investment company is trying to enter the US market. The company is now expected to launch its first commercial batch in 2019. Additionally, it has also received a total of USD 35 million in funding. Additionally, it has also received a total of USD 35 million in funding. RWDC Industries raised USD 22 million in Series A3 round led by Vickers Venture Partners and Eversource Retirement Plan Master Trust. The remaining funding company received USD13 million for Series A2 led by Vickers Venture and WI Harper to produce plastic alternatives. This fund will primarily be used to significantly increase PHA production capacity in Georgia, the US, and it will also support its R&D efforts for prioritized applications.

In 2018, RWDC won the first Liveability challenge, based on a proposal to use PHA to start replacing single-use plastics, which is presented by Temasek Foundation Ecosperity and organized by a sustainability media organization Eco-Business.

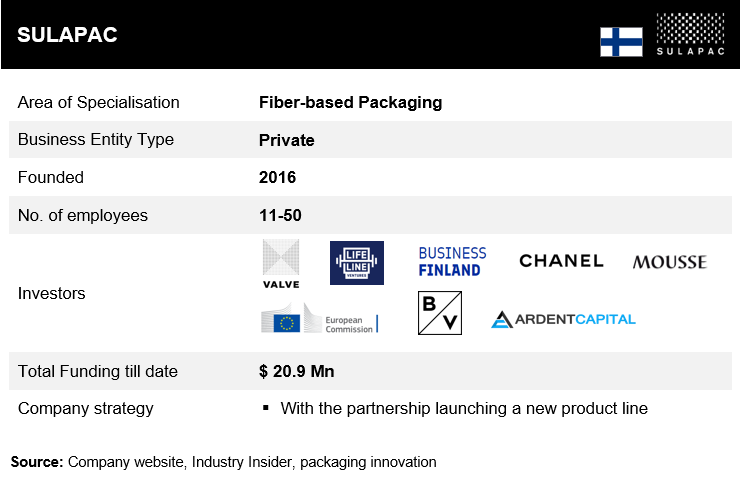

Sulapac is expanding its biodegradable packaging product portfolio

Sulapac is a Finland-based startup founded in 2016 by Dr. Suvi Haimi and Dr. Laura Tirkkonen-Rajasalo. It is an eco-friendly, biodegradable, and microplastic-free material made entirely from sourced raw material. Sulapac is a fully biodegradable and microplastic-free material, made of sustainably sourced wood and natural binders. The material is recyclable via industrial composting. Sulapac packages can be manufactured using injection molding, extrusion, and blow molding techniques. This packaging material has properties like plastics and those properties are improved by using Sulapac barrier coating water, oil, and oxygen resistance properties.

Sulapac has collaborated with Stora Enso to bring the sustainable straw in the market. The straws are based on the company’s patent-pending material innovation, and the main components of these renewable materials are wood and plant-based binders. This straw will be first available in the European market. Recently Fazer (Finland) has collaborated with Sulapac to launch compostable packaging for pralines. The first output of this collaboration is a traditional handmade box praline, which is available in the markets since November 2019. The company has received USD 20.9 million of total investment.

In December 2019, Sulapac raised funds of USD 16.24 million to expand its footprint in the sustainable packaging segment. The funding was received from Chanel, Mousse Partners, Sky Ocean ventures, Bonnier ventures, and Lifeline ventures, accompanied by a group of private investors. In February 2019, Sulapac won Worldstar Awards with the Kohinoor Jewellery packaging. This competition is a world championship competition in the packaging industry, which is organized by the World Packaging Organization (WPO).

The company has a patent on the topic of Novel materials for packaging. The patent relates to composite materials suitable for melt processing. In particular, the present invention concerns compositions comprising a continuous matrix of a thermoplastic polymer and wood particles distributed within the matrix. It also covers a method of producing composite materials as well as uses of such materials for producing articles, such as packaging, by melt processing.

References

Need a thought partner?

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur Clients

Our long-standing clients include some of the worlds leading brands and forward-thinking corporations.

- © 2021 Cheers Interactive (India) Private Limited. All rights reserved. FutureBridge ® is a registered trademark of Cheers Interactive (India) Private Limited.