Introduction

Food Preservation is required for both food safety and quality. It increases the shelf stability of the food by maintaining the color, flavor, taste, and texture. Food manufacturers have been using chemical preservatives such as benzoates, sodium diacetate, potassium lactate, nitrates. These chemical preservatives have been perceived to be harmful with various side effects, although these preservative have been approved safe by regulatory bodies

Various methods have been used for food preservation, which can broadly be divided into two categories:

- Physical Methods (High-Pressure Processing, Pulsed Electric Fields, Ohmic Heating, UV Light and Ozone, Active Packaging)

- Chemical Methods

- Synthetic (Antimicrobial, Antioxidants, Colour/Flavour additives, emulsifiers)

- Natural (Sugar, Salt, Vinegar, Spices, Citrus, Allium extract, Rosemary, Microbial Culture, Lysozyme, Bacteriophage)

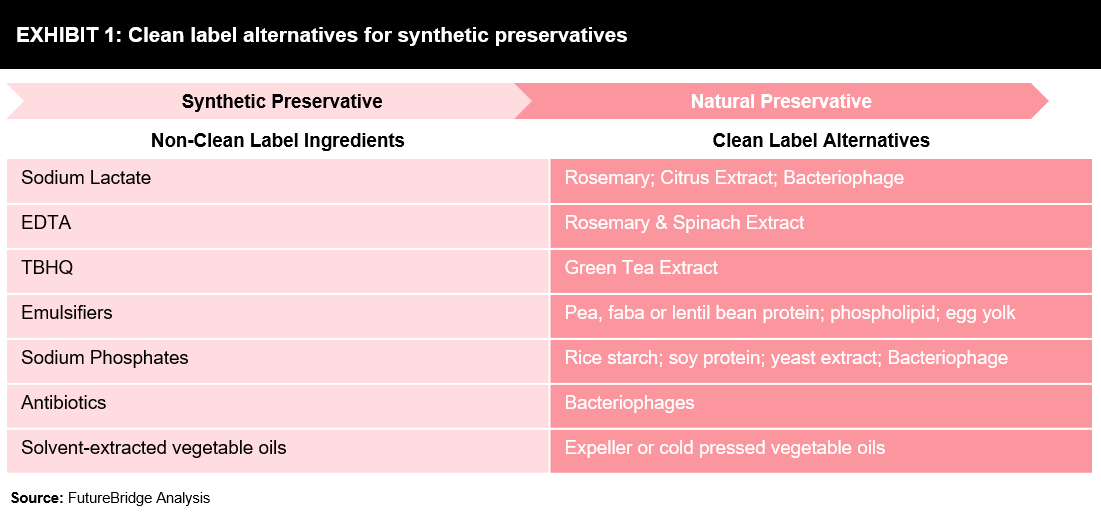

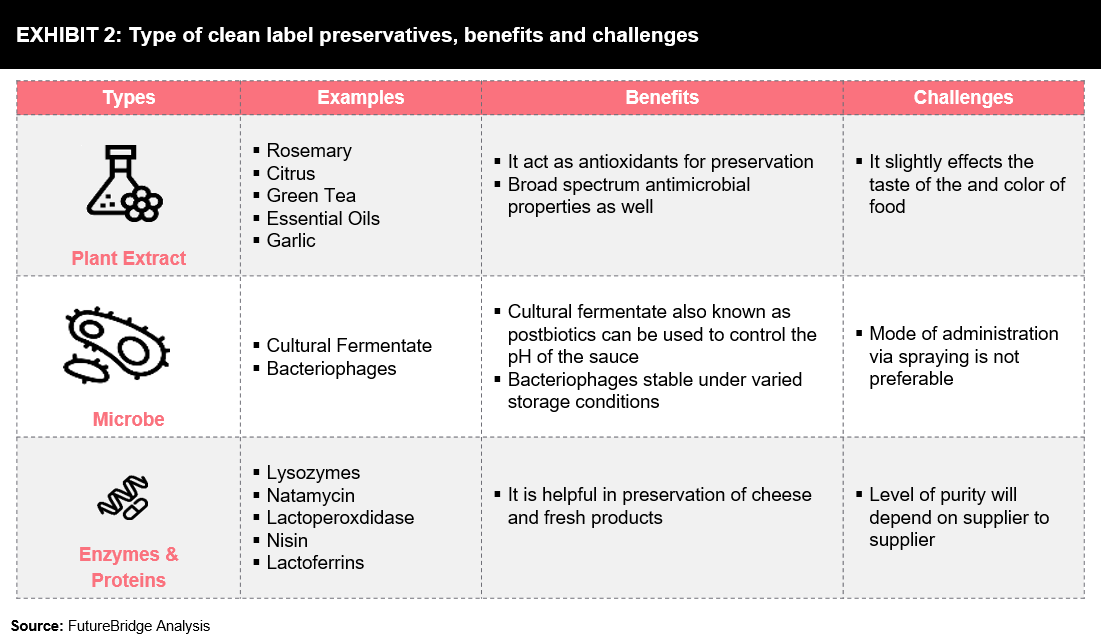

Emerging clean label preservation technologies preventing spoilage of food like the use of natural chemicals and physical methods are gaining more popularity.Clean label movement has grown as the consumer has become more aware label-conscious; thus, each ingredient used in the food is being scrutinized. This movement has led to an increasing demand for organic, natural, and not genetically modified ingredients.

Emerging clean label preservation technologies preventing spoilage of food like the use of natural chemicals and physical methods are gaining more popularity.Clean label movement has grown as the consumer has become more aware label-conscious; thus, each ingredient used in the food is being scrutinized. This movement has led to an increasing demand for organic, natural, and not genetically modified ingredients.

Bacteriophage – Clean Label Preservative

Biology & Life Cycle

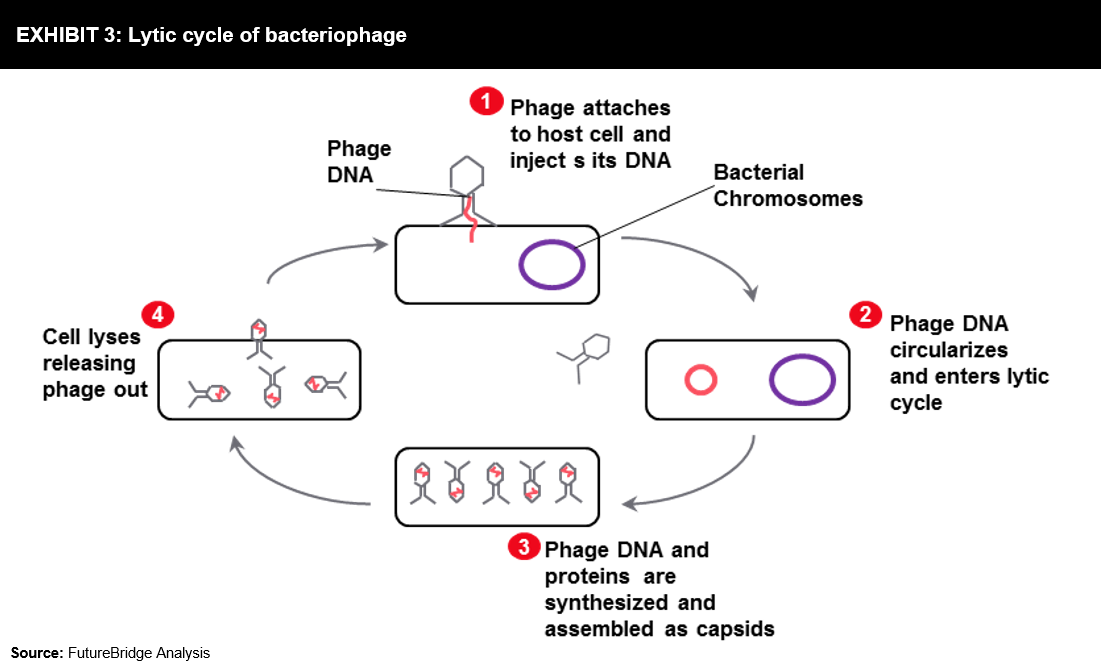

The bacteriophage is a bacterial virus as it utilizes bacteria as its host to complete its life cycle. Bacteriophages are also often referred to as “bacteria eaters” are an abundant form of life with a size of 20 and 200 nm. The page has a cell body with a tail. The tail comprises of protein, which helps the phage attach to the bacterial cell wall1. Phages are stable at pH (5 to 9). It gets inactivated by heating at 60 °C for 30 min2.

The phage life cycle is of two type

- Lytic (productive or virulent life cycle)

- Lysogenic (Temperate life cycle)

The lytic life cycle is the property that is explored for the use of phages in preservation. In the lytic life cycle, bacteriophage infects the bacteria, multiply within the bacteria, disrupts its metabolism, and finally lyse the bacterial cell. The time for the whole life cycle is 1-2 hrs 3.

Steps for adding Bacteriophages in Food

Phages are a clean label alternative for antibiotic preservation in the food and feed industry. Also, the restriction of antibiotics in animal husbandry, customer perception has led to the use of natural preservatives.

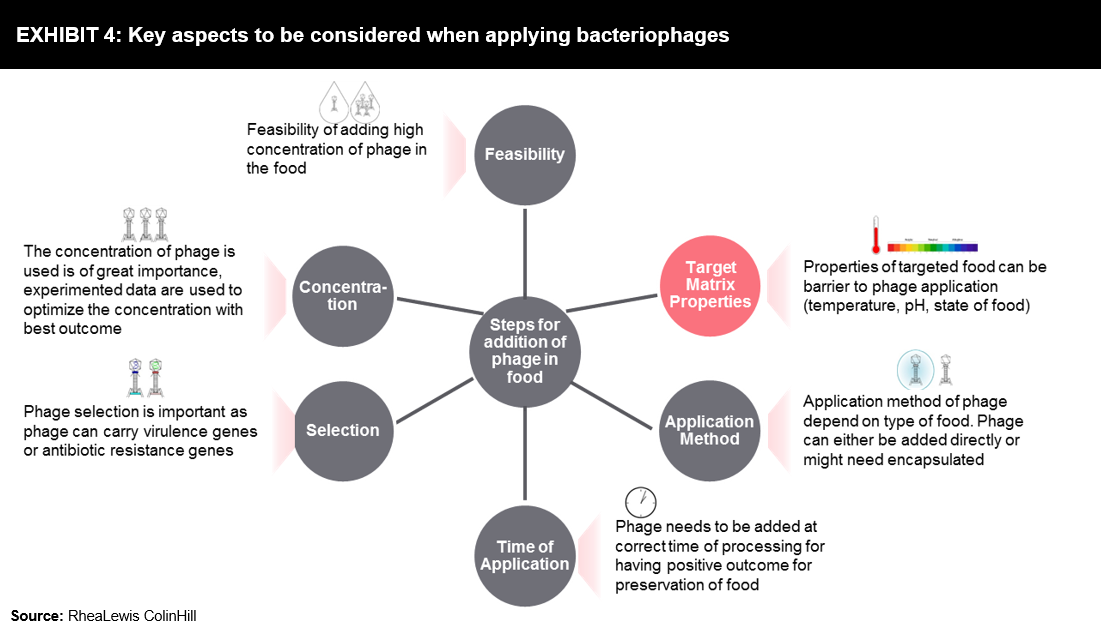

The bacteriophage is a natural antimicrobial with a narrow spectrum in food safety and production. Some steps need to be considered while adding bacteriophage as a preservative which includes:

- Phage concentration: The concentration of the phage is of great importance. Optimum concentration is required for the best outcome. For example, SalmoFresh at an MOI of 10^3 was significantly better than phage at an MOI of 10^2 to reduce Salmonella on chicken fillets 4. Listex P100 is more effective at MOI of 10^2 than an MOI of 0.1 for inhibiting Listeria

- Feasibility of adding high phage concentrations: It is mostly known that higher the concentration of phage is added, the more successful it is, but is it feasible to produce such high titer as it can be cost prohibiting.

- Properties of target matrix: The food-matrix like temperature, pH, minerals may be a barrier for adding the phages, so it needs to be carefully checked. For example, Salmonelex™ is more effected when it is diluted filter water and not in tap water as filtered water has reduced calcium, magnesium, and sodium 5. ListShield™, is more effective against Listeria monocytogenes, at 12°C than 4°C 6.

- The Application method of phages: Spraying and dipping are two most common ways of phage application, but for instance, the phages must be microencapsulation, which helps reduce the UV sensitivity and increase the survival of phages at pH 3–7 and extreme temperatures 7.

- When phages should be applied: Phage must be applied at the right stage of food processing to get a positive result and prevent spoiling bacterias to re-enter. For example, when SalmoFresh™ sprayed on sliced cumber, it effectively reduced Newport compared to unsliced cucumber 8.

- Phage selection: Phage selection is important as there is a risk of bacteria resistance, thus it is preferred to use mixes, cocktail, or interchange instead of using single phage.

Food Safety & Regulations

Bacteriophages are classified in the natural antimicrobial class. They effectively inhibit foodborne pathogens in the food industry.

Commercialized phage sare being utilized across various products and has also been approved by USFDA and USDA. In August 2006, PhageGuard Listex products of Micreos were active against Listeria, and Salmonella was FDA approved 9.

Phages do not eliminate the food pathogen completely instead help in the reduction of it. As per the European Union, the level of pathogens in food is acceptable if it is low, though there is an exception based on the target user (for e.g., Infants) where it is required to be completely absent.

The use of phages are currently being regulated, and it is applicable for the following

- Phages used for preservation in whole milk & skimmed milk reduce the pathogen Salmonella Typhimurium to permissible level 10

- Phages based product may be applicable for use in dry-cured ham as it inhibits Listeria monocytogenes below the detection limit (<10 CFU/cm2) 11

- Phages also reduce the level of Staphylococcus aureus in cheddar cheese to safety limit 12

Bacteriophages in the Food Industry

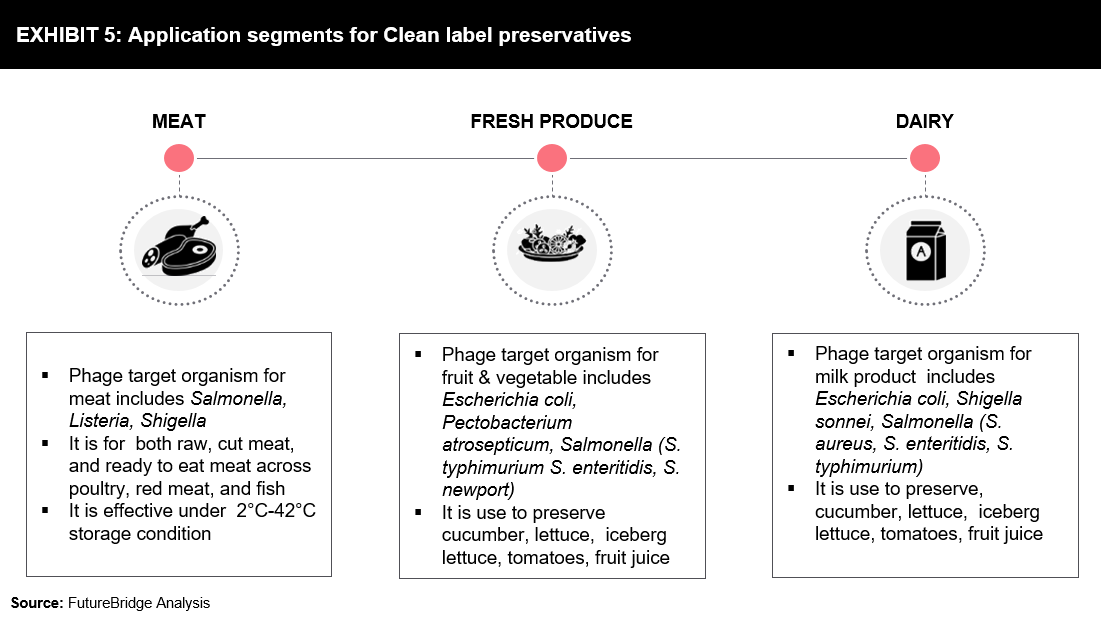

Phages are used across meat products, dairy products, fresh & processed vegetable & fruits products. It has a narrow spectrum antimicrobial. Each phage has a specific target organism. Commercialized technologies of phages are being explored in the food industry.

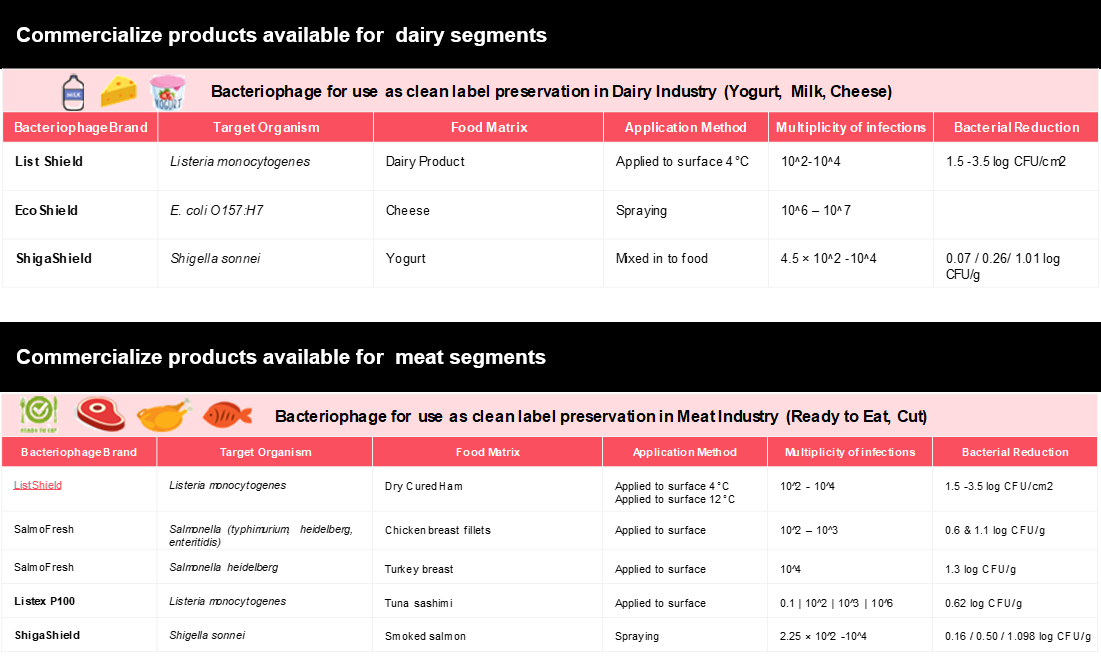

List of Commercialized Bacteriophages For Preservation

Commercialized products are available in the market, but a lot of research & fine-tuning is required. A few active players with the respective product includes:

- Handry markets two GRAS approved products PhageX AS, PhageX AL against Salmonella sp. and Listeria sp.

- Intralytix produces GRAS and FDA approved ShigaShield. EcoShield, ListShield, SalmoFresh against Shigella, Salmonella, E.coli, Listeria

- Micreos Food Safety BV commercialized FDA products which include PhageGuard Listex, PhageGuard S, PhageGuard E against Listeria, Salmonella, E.coli

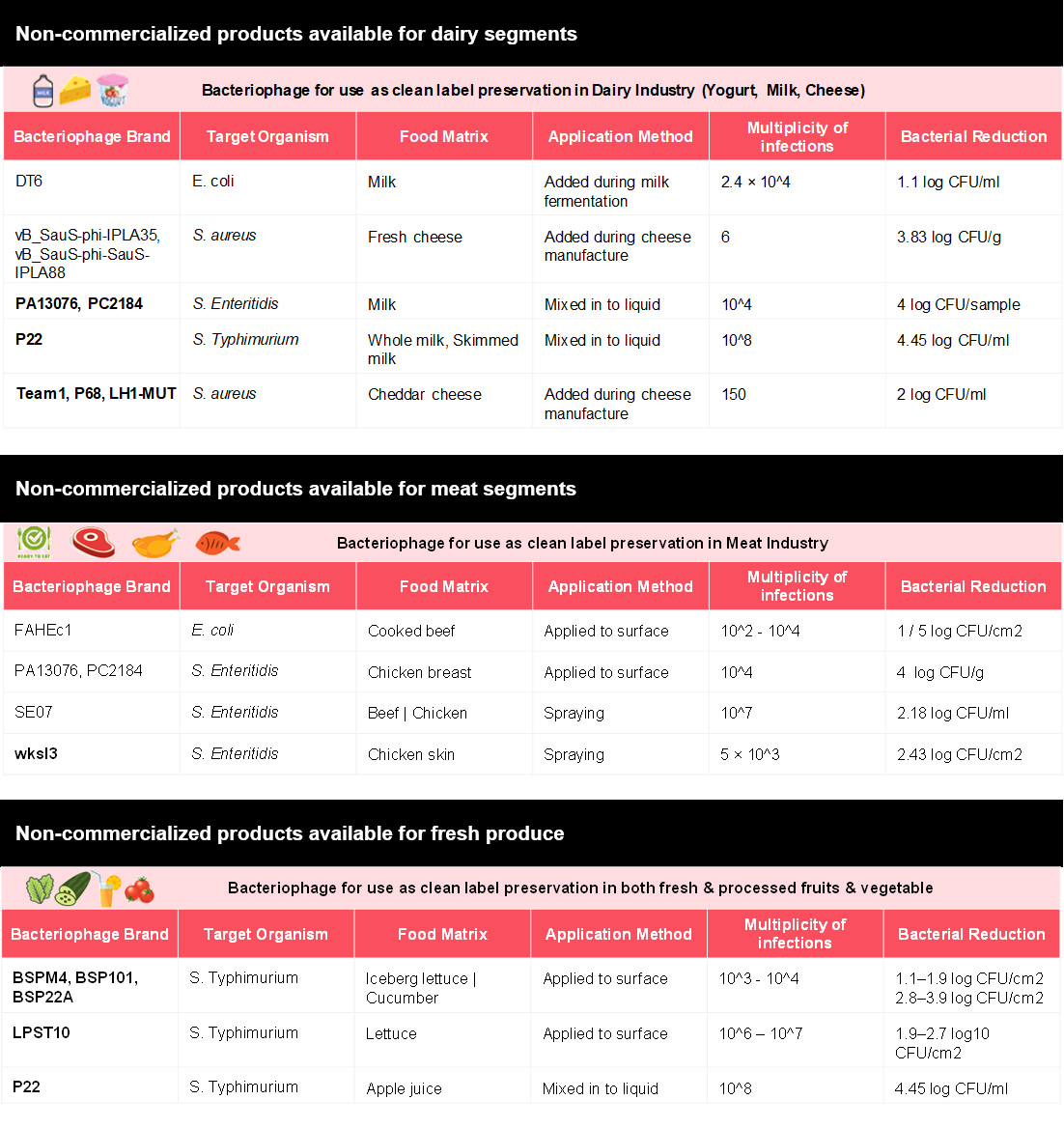

List of Researched Bacteriophages for preservation

There is a lot of research in this space across milk products, preferably preservation of cheese against Salmonella aureus. The use of phages in fruit juice and energy drinks are also being explored. Feed Industry is also exploring the area to replace antibiotics from the feedstock.

Below table list a few examples of research of phages across food industries:

Whitespace – Challenges & Opportunities

Phage specificity

- Bacteriophages are highly pathogen-specific

- Important to note that they do not offer broad-spectrum resistance

- Thus can be used across a product which needs narrow-spectrum preservatives like meat, cheese

Total pathogen elimination

- Bacteriophage use is limited due to its inefficiency to eliminate the pathogens

- Due to which it might cause a hindrance in adding it as a preservative in few products as per regulation which is as follow:

- Vegetable cuts (zero tolerance of Salmonella)

- Infant food & medical application (zero tolerance of Listeria monocytogene)

- Sprouts (zero tolerance of E. coli O157:H7)

Mode of application

- Current and mostly practiced method of application of phages on the food includes spraying or dipping

- These modes of application release the phage particles into the environment or can cause cross-contamination

- Thus new application method must be researched.

Phage resistant development

- With repeated usage, the scenario of the pathogen to attain phage resistance might be a challenge

- Phage resistant to a pathogen is still not been observed, but it might be possible

- Researches are being conducted where it would be necessary for the phages to be used as a mixture rather than a single strain, or rotate and use a different strain

Phage selection and designing

- The process of designing the product poses a significant hurdle with the parameters of concentration, selection, application mode, time of application, and processing methodology becomes crucial

- Phage are sensitive to certain pH and high temperature, thus now microencapsulated spores are being designed

Need a thought partner?

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur Clients

Our long-standing clients include some of the worlds leading brands and forward-thinking corporations.

- © 2026 Cheers Interactive (India) Private Limited. All rights reserved. FutureBridge ® is a registered trademark of Cheers Interactive (India) Private Limited.