Post-harvest losses, Supply Chain Procurement

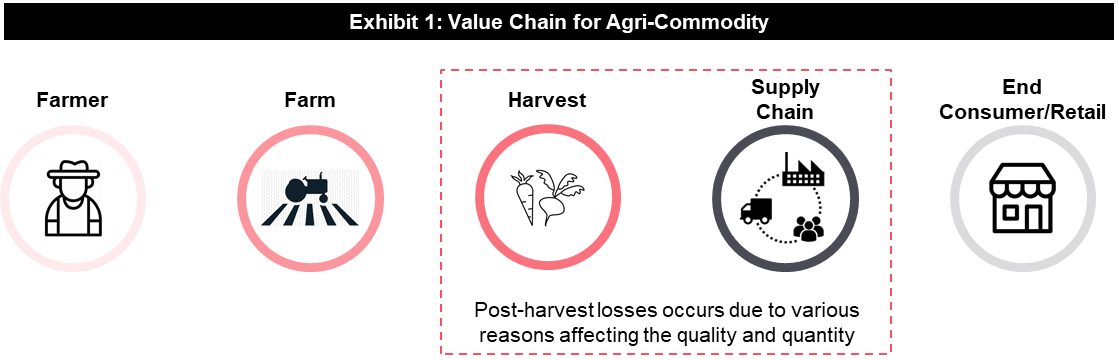

A major challenge with food currently is the losses observed after the harvest of the crop. This affects the entire value chain starting from the farmers who incur losses, the food processors and manufacturers who can be affected by a delay in production, and finally the consumer, who is largely unaware of the situation directly but faces the wrath in terms of a hike in prices.

Huge amounts of food are lost to spoilage and infestations, and the situation is rather bleak in the less developed nations with poor infrastructure, which is further compounded by the tropical weather. Post-harvest loss is seen in the form deterioration of quantity and also the quality impacting the nutrition. The observed rate of wastage can reach as high as 40-50% regularly posing a major cause of worry. Further, in developing nations, quantity losses happen due to processing, spoilage, insects, and rodents.

Fresh produce is biochemically active and hence exhibit changes during post-harvest. The produce undergoes enzymatic changes and exhibits variations in ripening stages too. Reducing these losses would immensely strengthen the global food supply and help in overcoming the challenges.

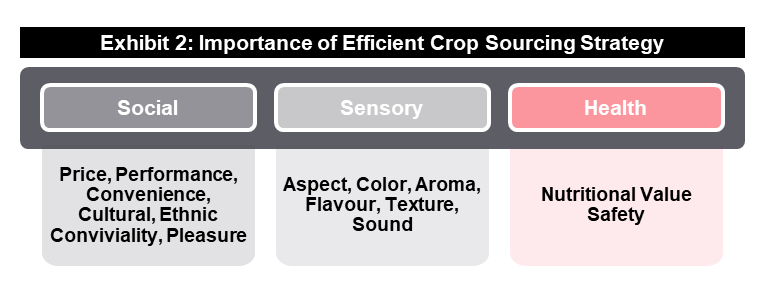

Some of the objectives of efficient sourcing should result in:

- Sustainable & profitable business

- Competitive pricing

- Lowest system costs (zero defect, no-waste)

Shared values throughout the supply chain

Challenges

The agri-food supply chain is a complex network of stakeholders working across various facets of the ecosystem. One of the key participants in the value chain includes the supply chain actors who are involved in sourcing and procuring of the agricultural harvest and help in reaching to the processors. The complexities in the supply chain do come with a fair share of challenges.

The following are the various types of challenges faced by the crop processors and food manufacturers.

Limiting post-harvest losses at the earliest point in the supply chain

Agriculture is a commodity that is decided by nature’s will and is affected by numerous factors. The entire life cycle of the crop is susceptible to these external conditions and can be affected by factors such as:

- Weather conditions

- Pest infestations and crop diseases

- Soil conditions

These factors result in an impact on the end harvest, and expected volumes may not reach the processors or manufacturers as expected. This can severely impact businesses.

An example of this scenario would be the citrus disease affecting the Florida citrus produce. The industry has faced a massive revenue drop by half, and losses are approaching $5 billion. It is paramount for companies to evaluate these sorts of situations and be able to work a solution.

Quality Compliance for Export and Food Safety

The produce is often region-specific and requires to exported and imported by the countries. To pass these quality standards, it is important for the crops to pass the quality tests and also the food safety norms.

Losses are observed in multiple scenarios:

- Harvest not meeting the necessary standards

- Loss of produce during transportation

Fluidity of produce transportation along the supply chain

Statistics shared by the “State of Food and Agriculture” have estimated a massive loss of 14% post-harvest and pre-consumer use. This has boiled down to the inefficient logistics.

In Africa, 20% of staple foods in sub-Saharan Africa are lost before they reach the market. This figure rises to approximately 40 to 50 percent for fruit, vegetables, and tubers with the cost of post-harvest loss rising to US$4 billion per year.

A well-structured, organized, and well-communicated are essential for ensuring the safe passage of the perishable goods and maintain it fresh as long as possible.

Additionally, to these factors, there is another key aspect when it comes to sourcing. This doesn’t directly impact the process of crop sourcing, but it indeed decides on the complexity of the sourcing process.

Palm oil is one of the hugely used commodities, but it can be rated as one of the highly disputed or controversial commodity. Major concerns are surrounding the sourcing of palm oil, forcing the big players to search for alternatives to palm oil.

Interventions which can overcome the post-harvest inefficiencies

Crop losses are observed at multiple points along the supply chain and are not confined to a single unit. One of the reasons companies have failed in the past to address the issue is that they were being executed in bit-parts but not along the entire chain. Therefore to effectively address the problem, solutions need to span the entire chain.

The stakeholders need to be equipped with knowledge and awareness and implement the advancements in procuring technologies. Furthermore, only market-led solutions offer the scalability required for system change along the supply chain.

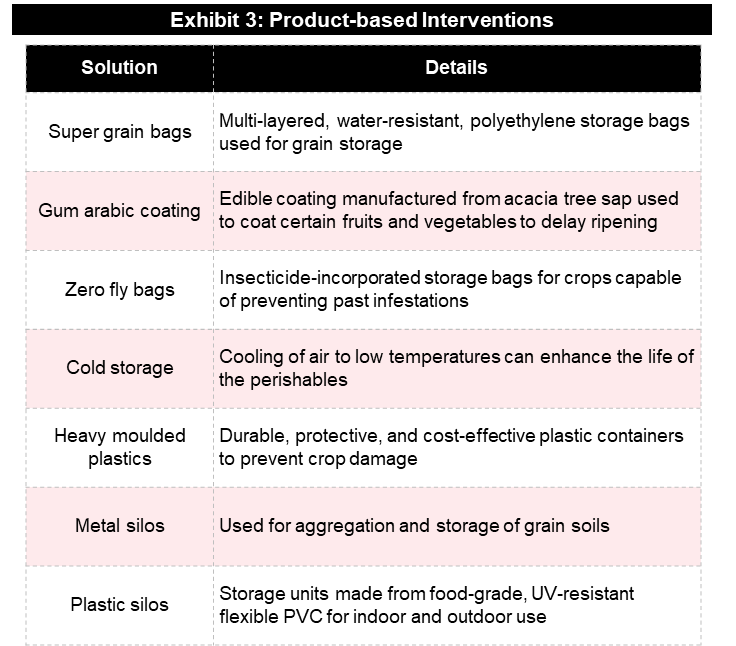

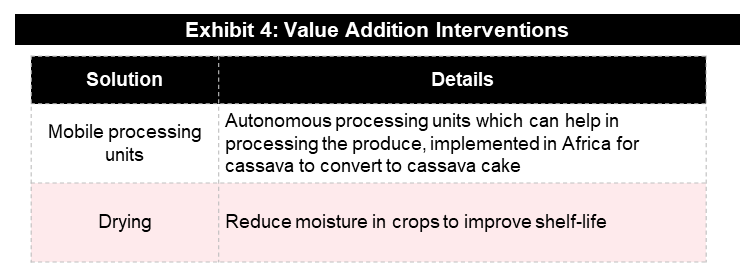

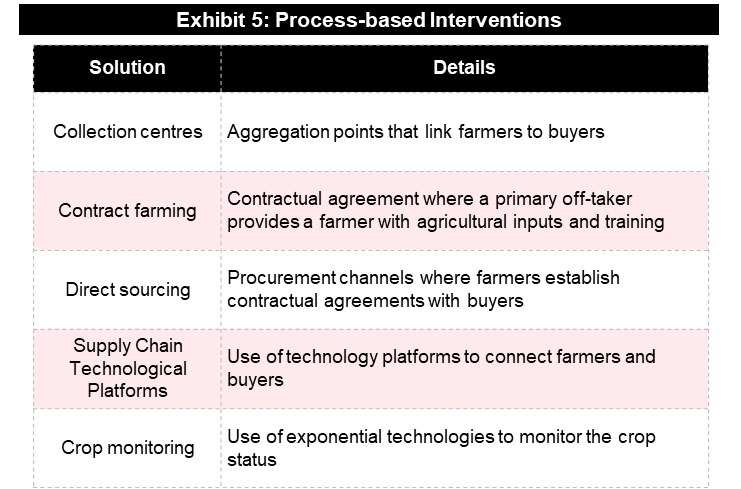

Product Solutions

Following three exhibits present different types of solutions to prevent the losses

A. Storage and handling

B. Value addition solutions

C. Procurement Solutions

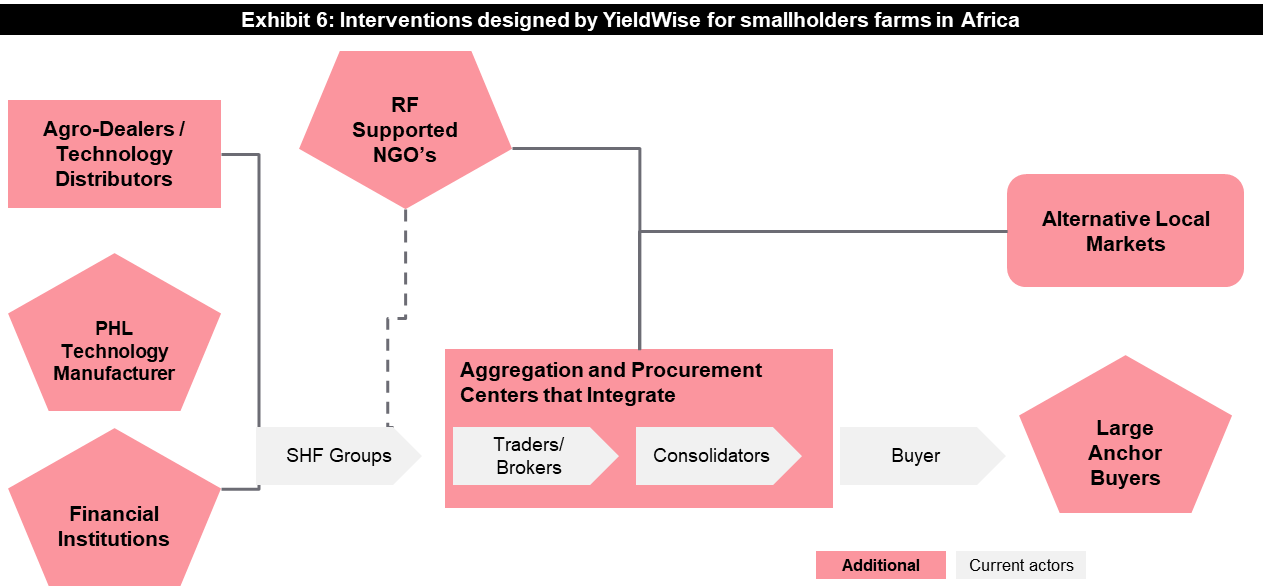

Case-study – Intervention by Yieldwise for Mango produce in Kenya

YieldWise worked with multiple stakeholders to reduce postharvest food loss.

Key partners for the activity were:

- Meru Greens Horticulture, Kenya-based fruit and vegetable exporter

- Sunny Processors, Kenya-based processor of mango pulp

- AGCO/GSI, provider of agricultural equipment

- TechnoServe, a non-profit organization that develops business solutions to poverty

- The Coca Cola Company, the beverage company sourcing for its African juice products

A local farmer business 1organization, owned and operated by a group of aggregated farmers

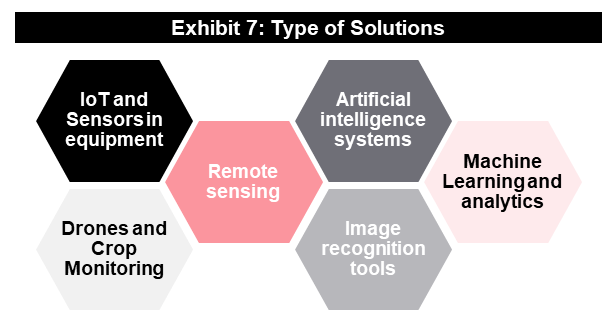

Adoption of Exponential Technologies for Crop Sourcing

Exponential technologies such as blockchain, artificial intelligence are being used increasingly to improve the efficiency of the sourcing of the agri-commodities.

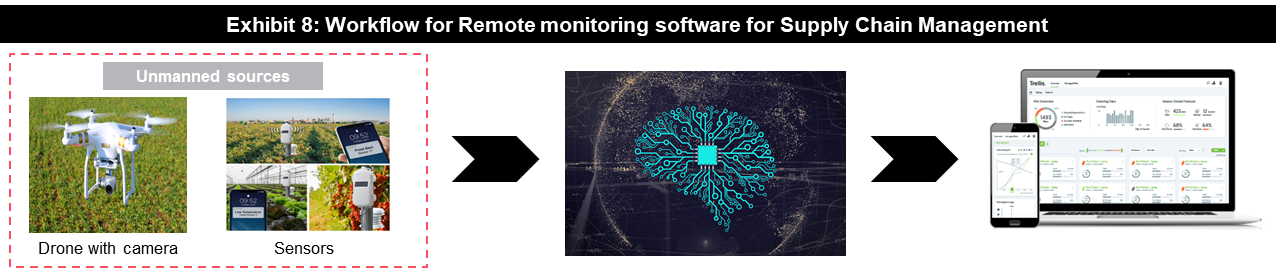

The typical workflow of the system functions inflow starting with physical detection devices and is followed by integration with machine learning or artificial intelligence and culminates with providing insights for the supply chain manager.

- Data Sourcing from the field:

- Data collected from unmanned sources, preferably aerial vehicles such as drones

- Data gathering process conducted regularly by the unmanned source, scheduling can be customized

- Image analysis to be conducted by the software in the drone-based on the parameters such as color, rootstock, chlorophyll content

- Data upload and processing:

- Data gathered by the device will be fed into the software platform

- The software platform is designed to analyze the quality and yield of the crops

- The technology for the platforms can be based on artificial intelligence

- The platform can help in predicting or forecasting the requisite parameters such as yield and quality

- Result and Insight generation for Supply Chain:

- The data analyzed by the software platform to generate predictions will be uploaded in a cloud link

- The data will be conveyed on an interface

Generated data of yield and quality will be provided to the Supply Chain personnel helping them plan the procurement strategy accordingly.

Currently available commercial solutions are provided by companies like Trellis, CropIn and SourceTrace.

Supply Chain Insights by Trellis

Trellis, an Israeli company, is providing real-time artificial intelligence recommendations to optimize the supply chain.

Field Ops Performance:

- Predict field treatments impact on sourcing goals, and helps in managing the agro-technical operations to improve your yield.

- By analyzing data from across the network’s fields and growers, Trellis can quantify the impact of specific field operational activities and isolate them from external factors, like weather, crop disease, and more.

Harvest Booking:

- The platform helps in aggregation of the relevant information for making informed decisions regarding harvest schedule, order, and priority.

- The platform considers crop status, manufacturing and storage capacity, timing goals, quantities, and can even recommend how many trucks to send to each field.

Crop Performance Drivers:

- Helps in coordinating the cross-organizational efforts by learning from past activities, and offering insights for improving performance across different environmental conditions, such as seasons and weather.

- The software incorporates harvest drivers such as timing, field inputs, varieties, grower profiles, locations, etc.

References

- https://www.sourcetrace.com/blog/cutting-post-harvest-losses-bottom-approach-increasing-food-security/

- http://www.agritrade.org/events/documents/Johr.pdf

- https://www.cropin.com/blogs/5-biggest-challenges-in-sourcing-procuring-agri-commodity-how-do-agri-tech-solutions-help-overcome-them/

- https://www.washingtonpost.com/climate-environment/2019/11/09/end-florida-orange-juice-lethal-disease-is-decimating-its-citrus-industry/

- Beyond yields – how can collaboration improve post-harvest profits within smallholder supply chains?

- https://trellis.ag/platform/supply-chain-insights/

7 min read

7 min read