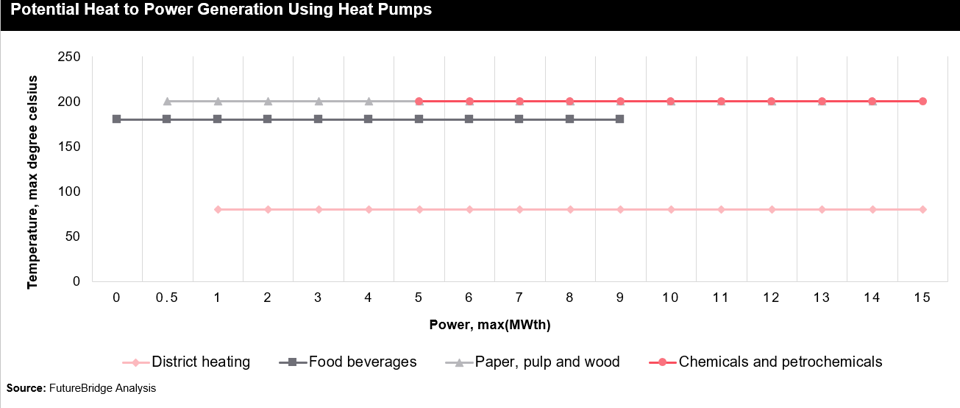

As the world decarbonizes, Industrial heat pumps find their application in a wide range of industries. These industries are responsible for around 15% of global industrial CO2 emissions and can significantly reduce their carbon footprint through the adoption of heat pump technology.

Dominant fields for heat pumps

-

- Food and beverages

- Pulp and paper

- Chemical industry

-

District Heating System (DHS):

Heat pumps are vital for district heating, which accounts for about 1% of CO2 emissions and relies over 90% on fossil fuels. DHS distributes heat to multiple buildings, utilizing low-temperature waste heat sources and upgrading them to higher temperatures, minimizing heat losses.

District heating is significant in China, Russia, and various European countries. In the EU, 65% of district heating depends on low-cost fossil fuels, with Germany and Poland exceeding 80%. Heat pumps have strong emission reduction potential, with several decarbonization projects announced[5].

What government policies could bring strong economic growth

- Supporting the reuse of excess heat from processes and industry

- Stimulating the development of DH grids

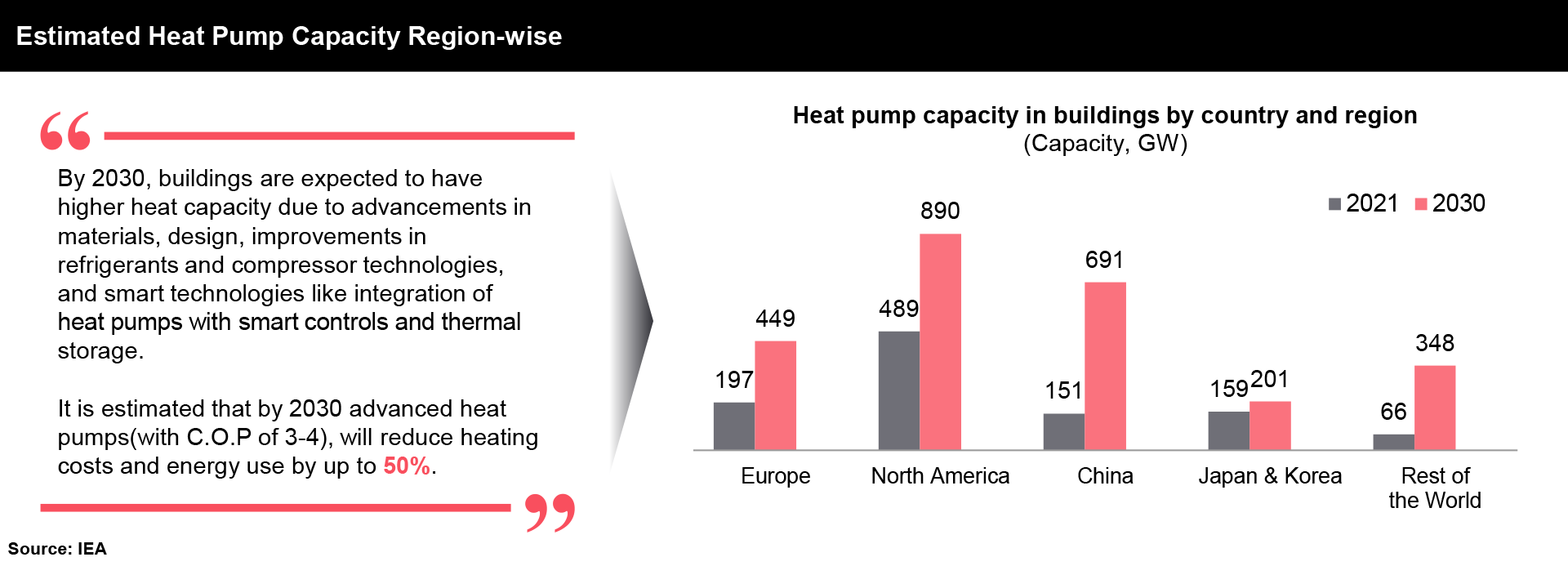

Governments are increasingly issuing regulations and support for heat decarbonization in industry and district heating. In the EU-27 plus the United Kingdom, the largest demand center for heat pumps today, heat pumps are expected to be responsible for about 15 percent of total district heating and 20 percent of industry heating processes for temperatures up to 200°C in 2030.

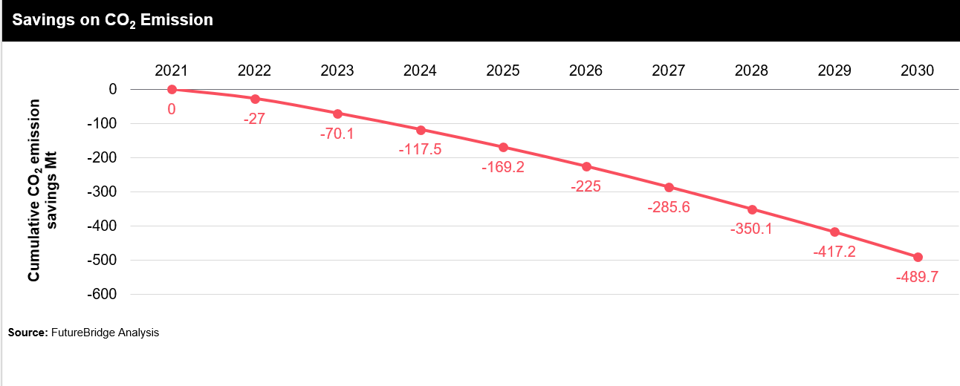

Heat Pumps turned out to be an efficient tool: Carbon Abating

Heat pumps are a promising landscape for mitigating CO2 emissions. Mechanisms like waste heat utilization, decarbonization of district heating and Grid Services, and Load Management when integrated with heat pumps, enhance energy efficiency, utilize renewable energy, and reduce reliance on fossil fuels. Hence abating GHD emissions.

Several notable decarbonization projects using industrial heat pumps in district heating or waste heat utilization include:

- Copenhagen, Denmark: The Amager Bakke waste-to-energy plant integrates large-scale heat pumps to utilize waste heat for district heating, aiming to reduce CO2 emissions by 100,000 tons annually.

- Stockholm, Sweden: The city’s district heating system has incorporated industrial heat pumps to capture and upgrade waste heat from data centres and wastewater, significantly cutting fossil fuel use.

- Munich, Germany: The Stadtwerke München (SWM) utility company has invested in large heat pumps to harness geothermal energy and reduce reliance on natural gas for district heating, targeting a 70% reduction in CO2 emissions by 2030.

- Helsinki, Finland: The Hanasaari power plant project includes the use of heat pumps to utilize seawater and waste heat, to make Helsinki’s district heating carbon-neutral by 2035.

- Vienna, Austria: The Spittelau waste incineration plant uses heat pumps to convert waste heat into district heating, contributing to Vienna’s ambitious climate goals.

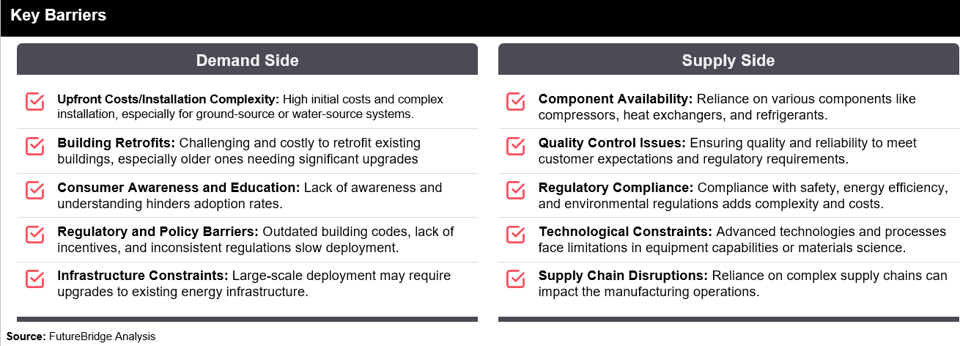

Key barriers to accelerating the deployment of heat pumps

Heat pump adoption faces demand-side and supply-side barriers, both area-specific and universal. Overcoming these requires government incentives, industry collaboration, consumer education, and workforce development. Addressing these challenges is key to reducing carbon emissions, improving energy efficiency, and promoting sustainable heating and cooling[2].