The Future of Wind Blade Recycling: Driving Circularity to Composites Industry

Evolution of the Wind Energy Industry

At the end of 2019, the global cumulative renewable installed capacity amounted to 2537 GW; hydropower accounted for the largest share (47%) of the global total, followed by wind energy (25%) and solar energy (23%). In 2019, the 60.4 GW of new installations (YoY growth of 19%) brought global cumulative wind power capacity up to 651 GW. In the onshore market, a new installation of 54.2 GW took place, an increase of 17% compared to 2018.

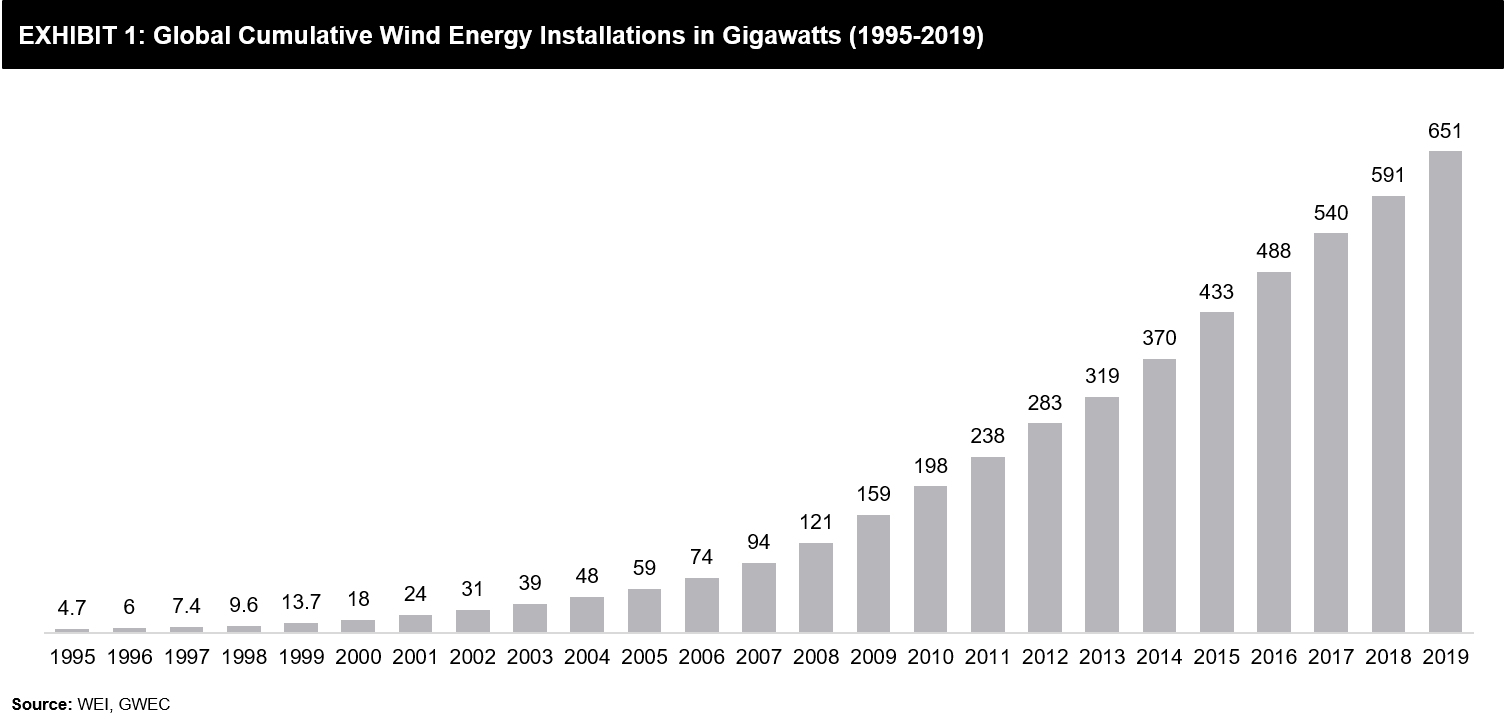

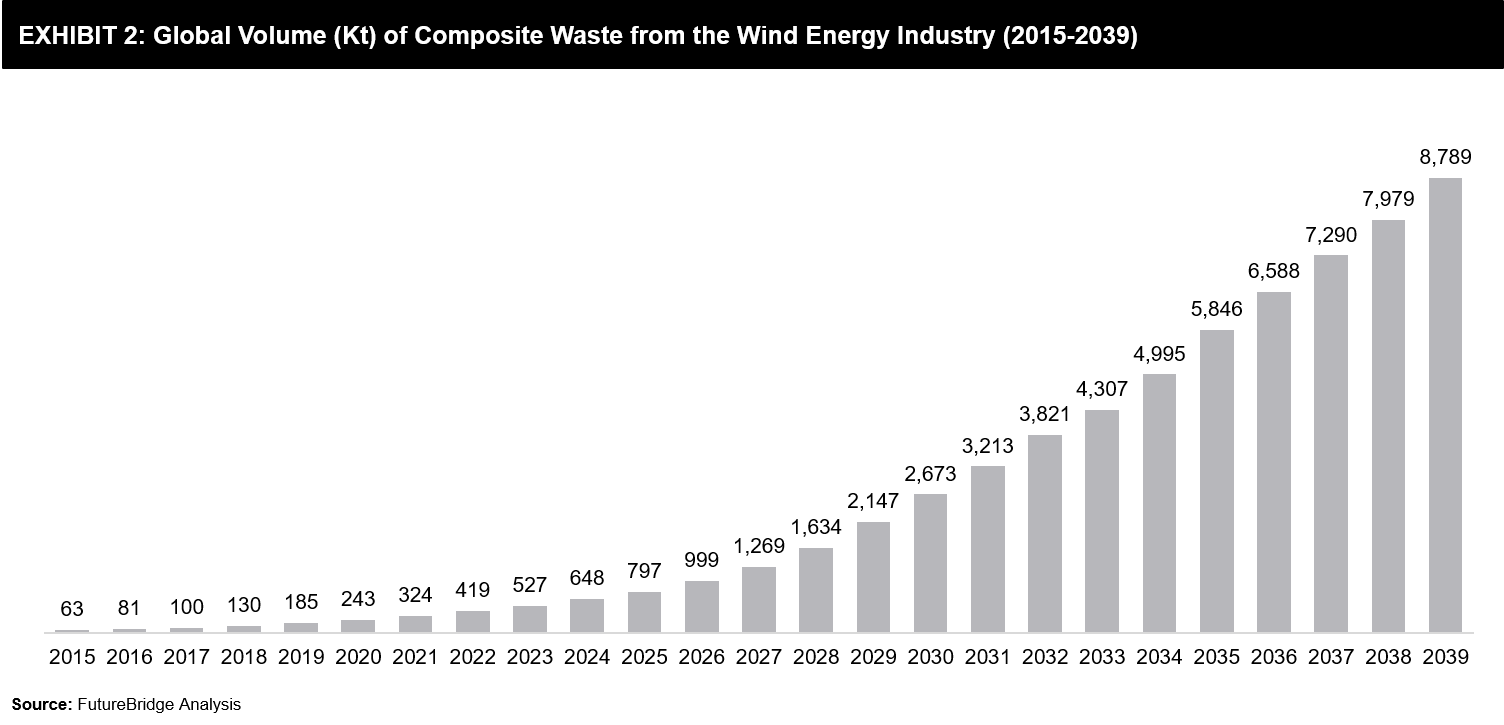

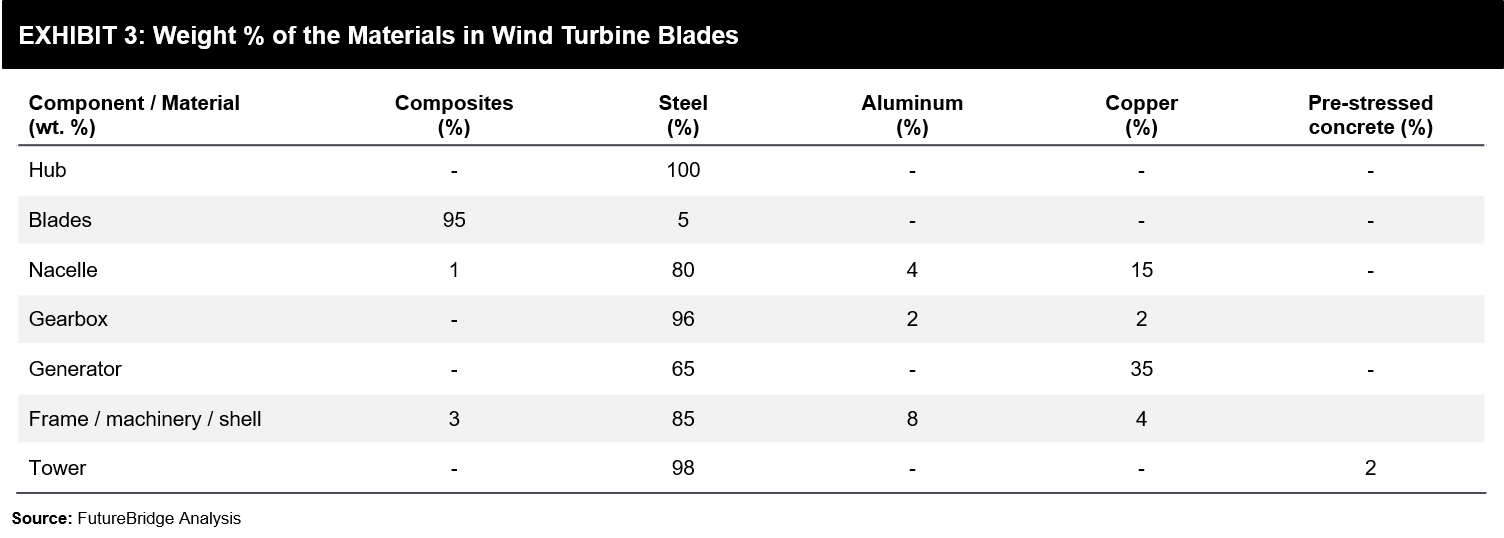

The global demand for wind energy has increased from 4.7 GW in 1995 to 651 GW in 2019; the annual growth rate is 19%, which is much higher than hydropower, capacity increased by 12 GW (+1%) and bioenergy (increased by 6 GW, +5%) and Geothermal energy (increased by 700 MW). Wind turbines generate electricity by turning kinetic energy from the rotation of the wind blades; a typical wind turbine consists of many components such as wind blades (the most important), gearbox, electric generator, and tower. Wind blades, largely made of composite materials, are expected to have a relatively long service life of about 20 to 25 years. Due to the exponential increase in wind energy installations, it is clear that a large number of composites waste streams from these wind blades would be generated. However, a considerable number of wind blades are expected to reach their End-of-life (EoL) in the future, hence, there will be a huge number of wind blades waste streams by ~2040. It is to be noted that the amount of composite materials used in wind blade is between 12-15 tonnes per MW. It is anticipated that the total amount of wind blade waste would reach 8,789 Kiloton (Kt) in 2039, currently, it stands at 185 Kt, pushing the need for recycling even further.

Wind turbine blades are generally made of the reinforcement fibres (60%) such as glass fibres/fabric, carbon fibres, matrix materials (35%) such as thermosets like epoxies, polyesters, vinyl esters, polyurethane and sandwich core (4%), e.g. balsa wood, foams such as polyvinyl chloride, polyethylene terephthalate, etc. and others (1%) such as metals and coatings. The complexity of thermosets material requires specific processes for the recycling of wind  turbine blades.

turbine blades.

Wind Blades Waste Projections

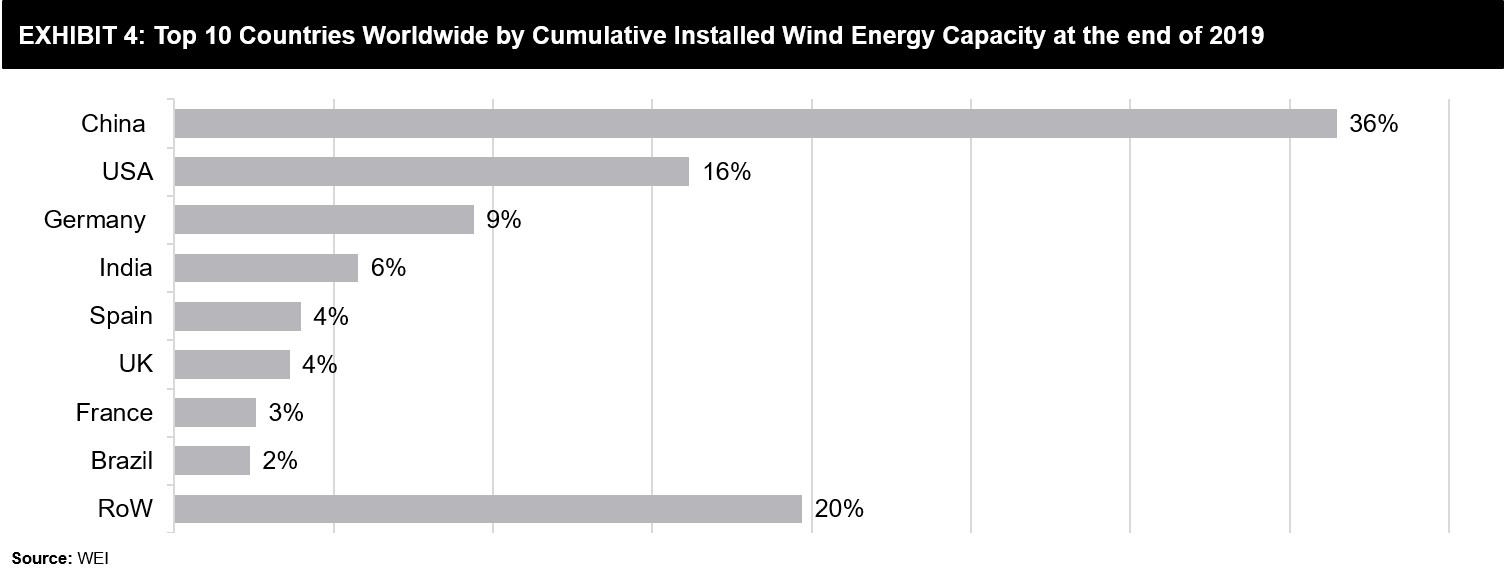

Composites waste streams will increase alongside worldwide wind energy deployment. As shown in Exhibit 1, global cumulative wind energy deployment accelerated after 2000 and has grown exponentially, reached 651 GW in 2019. The major global wind energy leaders today include China (237 GW of cumulative installed capacity), the US (105 GW), Germany (61 GW) and India (37.5 GW).

Most waste is typically generated during two primary life cycle phases of wind blades: a) blades production, b) EoL disposal of the wind blades. It is assumed that waste generated (<1%) during the production is easily managed, which is collected and treated by waste treatment contractors or manufacturers themselves. At present, wind turbines have a recyclability rate of 85% to 90%, however, the recycling rate of wind blades is negligible (1-2%). Various stakeholders within the value chain are developing and investing in novel recycling technology, for example, in 2019, WindEurope, the European Chemical Industry Council and the European Composites Industry Association have initiated the joint project to advance recycling of wind turbine blades, and, Re-Wind project is also exploring the potential reuse and recycling of the wind blades.

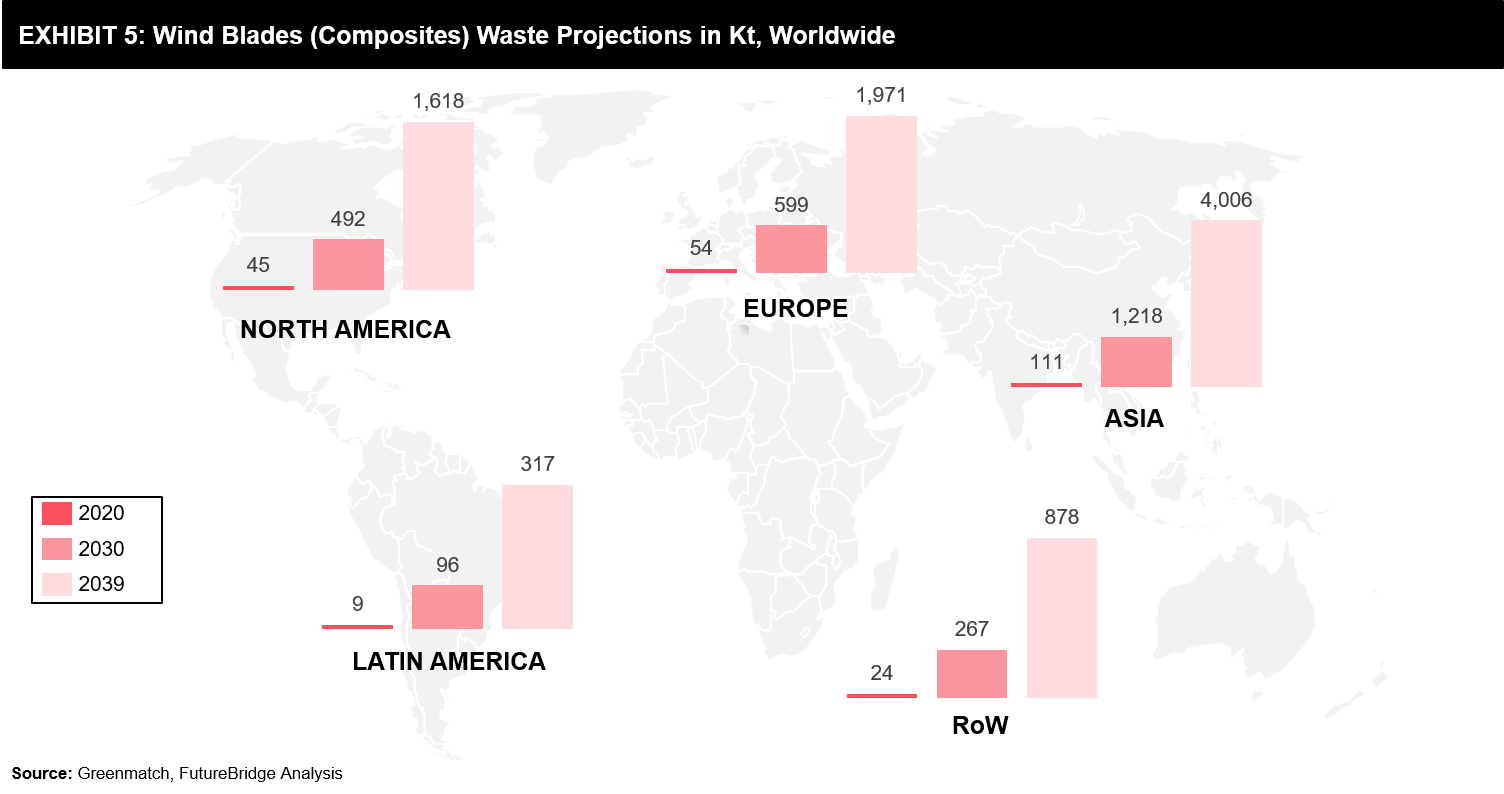

It is estimated that 8,789 Kt of composites waste from wind blades will be generated globally in 2039, which shows ~47.5x jump from the 2019 (185 Kt). Exhibit 5 shows the composite’s waste projections from wind blades by countries. Considering the worldwide surge in wind energy deployment since 2000 and an average lifetime of 20 years for wind blades, waste volumes are certain to increase more rapidly after 2025, from 999 Kt to 8,789 Kt in 2039. In 2039, the top three wind blades waste generation countries are expected to include China (3,200 Kt), the US (1,400 Kt), and Germany (824 Kt).

Wind energy is expanding faster in the Asian region than anywhere else in the world, but no country in the region has adequate wind blade recycling laws. There are currently no worldwide-level targets for the reuse and recycling of wind blade waste, except Germany, that has enforced a landfill ban on wind blades.

Wind Blade Waste Recycling Options

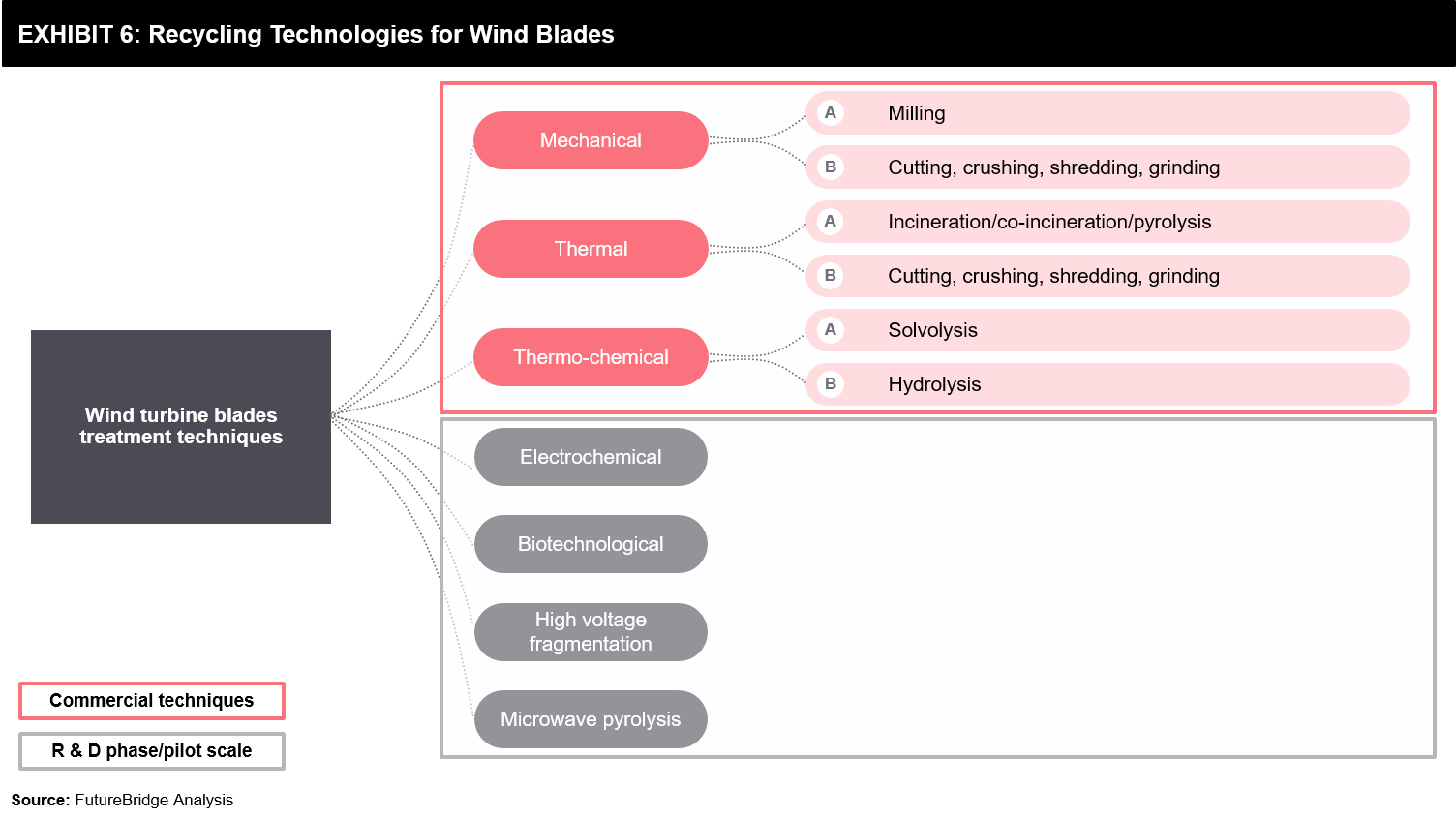

Currently, research and development into wind blade recycling are being carried out mainly in Germany, France, China, and the US. At the moment, there are few established technologies for the recycling of wind turbine blades, and only 30% of composites waste can be re-used to form new composites products, while the remainder is serving to the cement industry as filler materials. Currently, wind blades waste streams are commercially recycled through cement co-processing; however, development and industrialization of alternative technologies such as solvolysis, hydrolysis, and pyrolysis will provide impetus to the wind blade recycling. Exhibit 6 shows the recycling technologies for the wind blades.

Value Chain

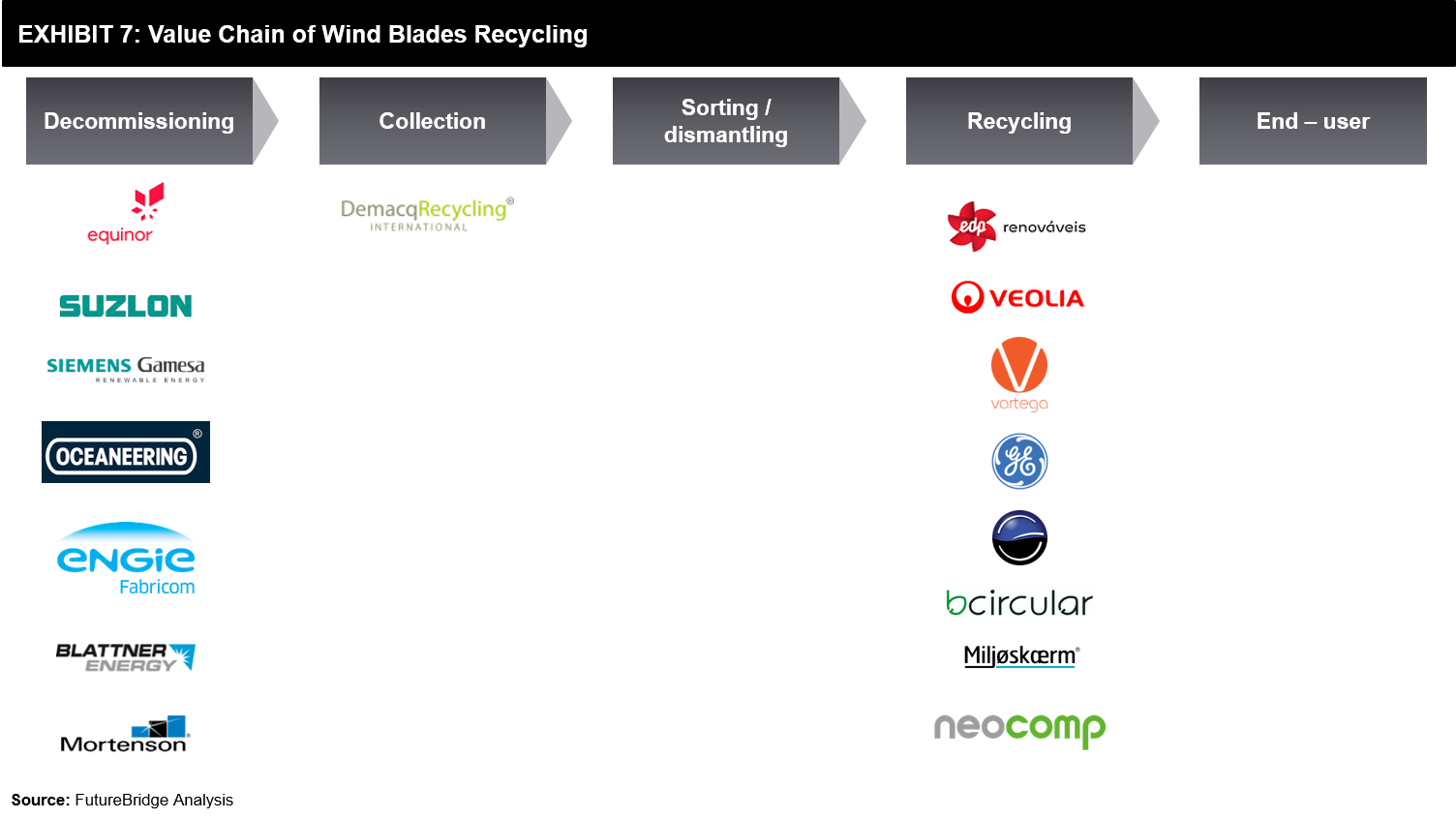

Wind blades recycling industry involves many different activities, from decommissioning of the wind blades to the collection, sorting, and recycling of wind blades. There are a limited number of companies that focus exclusively on wind blade recycling, many newcomers include small corporations for whom carbon fibers recycling is the core market. Recently, Global Fiberglass Solutions of Texas has announced a digital technology to support wind blades and the fiberglass waste recycling business. Neocomp GmbH shreds decommissioned wind blades and production scrap at its recycling plant in Germany, and shredded/granular material is sent to cement manufacturer Holcim AG, which includes it in the feed to its cement-making kilns. Veolia is also offering recycling solutions for wind blades along in Germany. As of now, the value chain is unorganized and fragmented (50+ players worldwide).

Drivers and Barriers

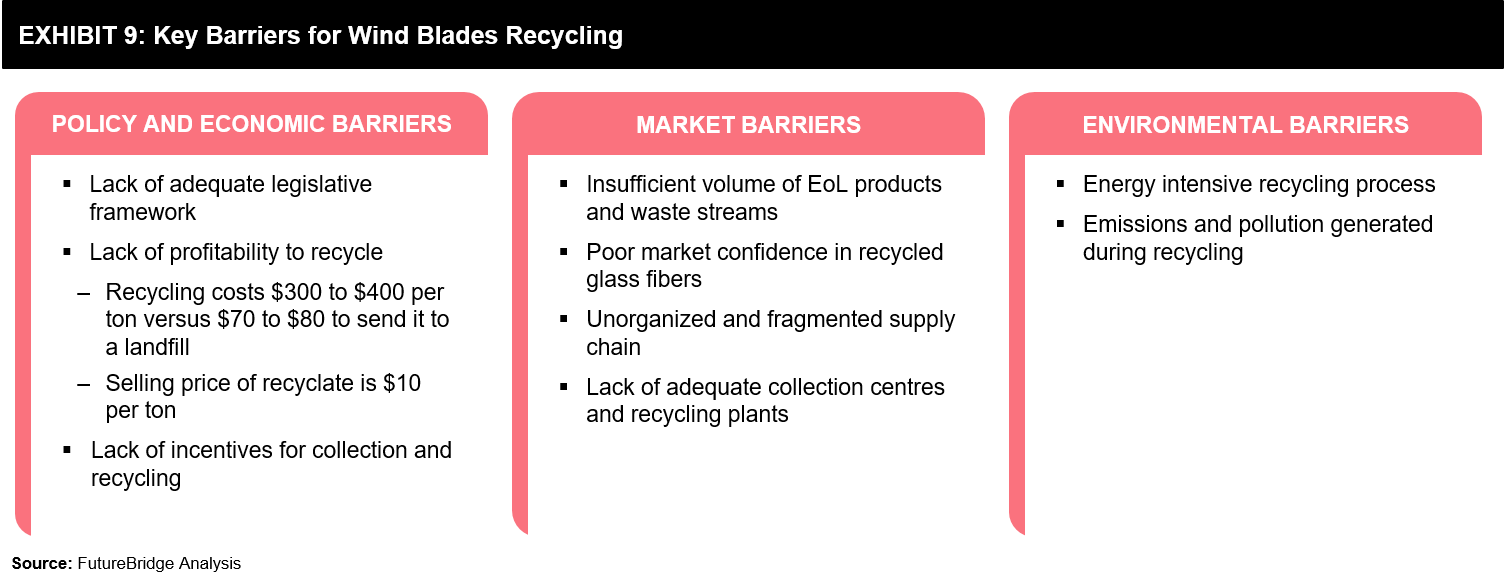

Developing an EoL management scheme for wind blades require the balancing of several factors such as high collection rate, high recovery and recycling targets, which are primarily driven by policy, economic, and market initiatives. Currently, the disposal of wind blades is not subject to specific regulation throughout the world, except Germany, wherein the landfill ban has been enforced for wind blades. It is worth noting that that wind blade recycling is not yet widespread, stakeholders within the value chain are busy laying the important groundwork to build the necessary collection, management and recycling systems, i.e., EoL management for wind blades. Exhibit 8 & 9 shows the key drivers and challenges for wind blades recycling.

Future Outlook

Wind energy is growing and the number of installed turbines is increasing each year, wind turbines erected in the late 80s and early 90s are nearing the EoL, and those installed after 2000 will be reaching their EoL by 2020. Recycling is the most sustainable solution in which wind blades can be handled at the end of their useful life, not only from an environmental and social impact perspective but also in terms of resource and economic efficiency. At present, the recycling rate of wind blades is negligible (1-2%), however, it is expected to increase as stakeholders are developing and investing in novel recycling technology.

At the moment, there are few established technologies for the recycling of wind turbine blades, and only ~30% of composites waste can be re-used to form new composites product, while the remainder is serving to the cement industry as filler material. Recycling of wind blades is not the only option, although, some parts of blades can be utilized too. In the EU region, blade sections have been used for bus shelters and public seating in the Netherlands, and children’s playground items in several countries. In addition to this, marine structures and art installations are among other potential applications for reuse or repurpose of decommissioned wind blades.

References

- https://library.wwindea.org/global-statistics/

- https://gwec.net/global-wind-report-2019/

- https://www.greenmatch.co.uk/blog/2017/10/the-opportunities-of-solar-panel-recycling