Produced Water Management in Oil & Gas

Introduction

Produced water is a naturally occurring water that comes to the surface along with oil & gas. It is a by-product of all oil & gas extraction processes and co-exists in rocks, which trap hydrocarbons. Its contents vary depending on the chemistry of the rock that it has been in contact with. In some instances, it is several times saline than seawater, and at times, it is less saline. Bakken and Marcellus shale reserves are good examples of high salinity, whereas California and Wyoming reserves are less saline than seawater.

This article examines different techniques used for the treatment of produced water and offers insights on the way oil & gas companies manage their produced water.

Characteristics of Produced Water

The properties of produced water are mainly dependent on the geographic location, geological formation, number of years for which it is in contact with the subsurface, and type of hydrocarbon that is being produced. The main constituents are dissolved and dispersed oil compounds, dissolved formation minerals, production chemical compounds, production solids (formation, corrosion, scale, bacteria, waxes, and asphaltenes), and dissolved gases.

- Dispersed oil: Oil in produced water is an important contaminant due to its tendency to interfere with the biological oxygen demand, thus affecting aquatic organisms and the marine ecosystem. With the current technology, droplets up to the size of 10 microns can be collected easily.

- Dissolved organic compounds: It includes organic acids, polycyclic aromatic hydrocarbons, phenols, and volatiles. The concentration of these compounds is more in water produced from gas condensate platforms than oil-producing platforms.

- Treatment chemicals: This includes biocides, reverse emulsion breakers, and corrosion inhibitors. At times, it may also consist of highly toxic chemicals with a high chemical mortality index.

- Produced solids: This includes corrosion products, clay, sand, silt, and other suspended solids from formation and wellbore operations.

- Bacteria: Anaerobic bacteria is one of the key reasons for corrosion.

- Metals: Lead, zinc, iron, barium, and manganese are some of the most common metals found in produced water.

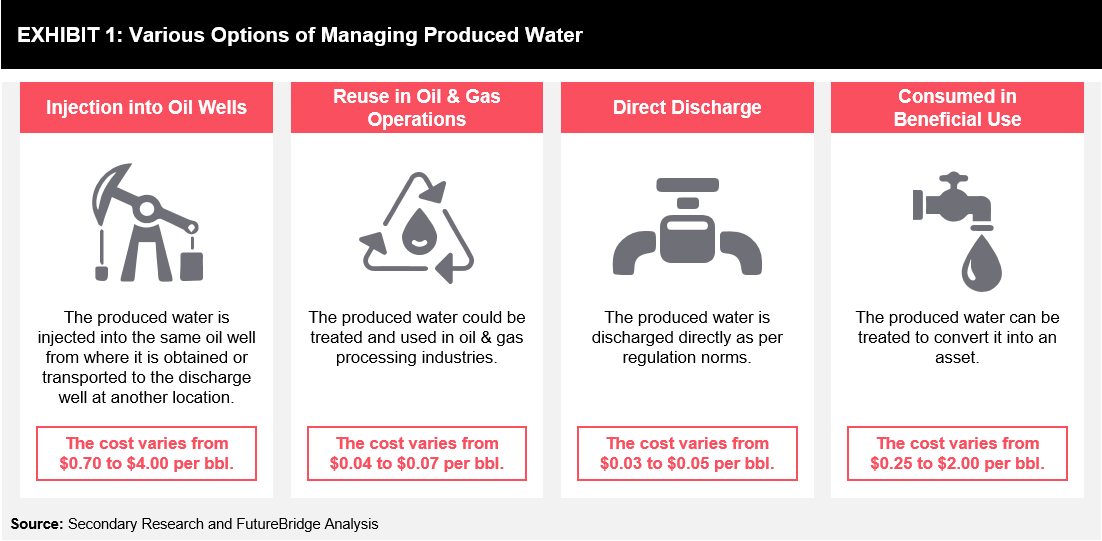

Options for Produced Water Management

The produced water is present in a significantly higher volume when compared to oil in reserve. Hence, its treatment or safe disposal is the primary concern.

Technologies for Produced Water Treatment

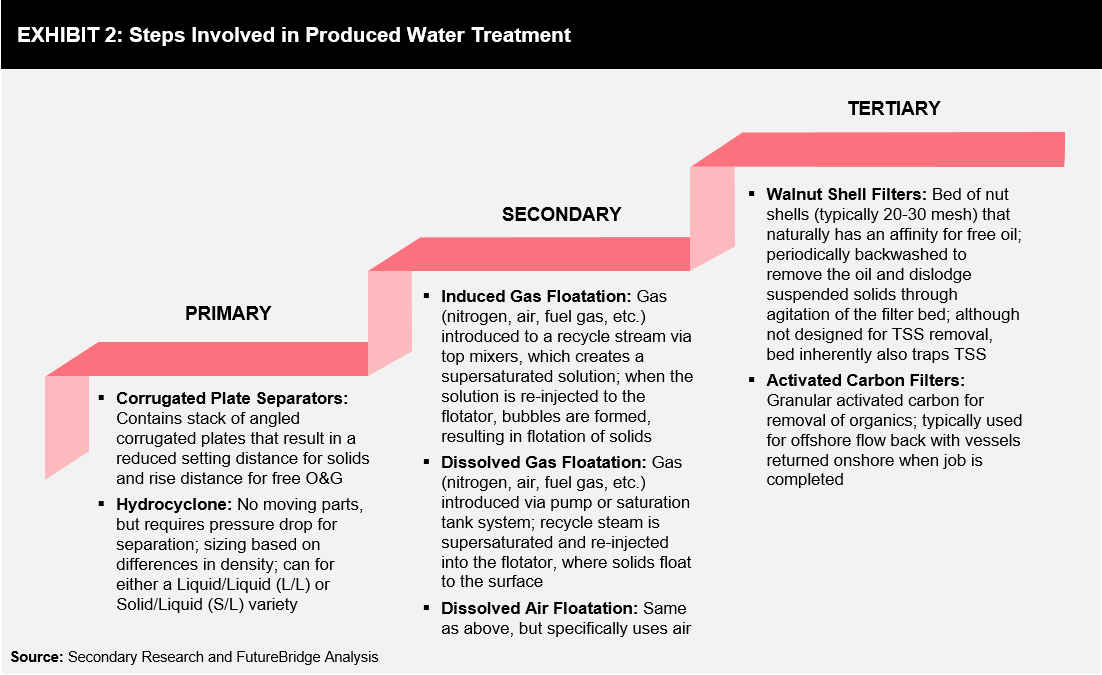

There are three different steps involved in the treatment of produced water, as shown in Exhibit 2.

The primary treatment removes the coarse size of TSS and free oil & gas droplets. The secondary treatment typically deploys a variety of flotation units, which introduces small gas bubbles (nitrogen, air, or fuel gas) to remove any solids, and in addition, may use chemical (coagulant and/or flocculants) for better removal efficiencies. The tertiary treatment is the next-level filtration wherein various filtration media are used to bring down the suspended solid level to ~10ppm concentration.

Key Players and their Technology Portfolio for Produced Water Treatment

- Aker Solutions: Offers subsea processing system that is a simple two-phase to three-phase separation unit with oil boosting, re-injection of produced water, and gas treatment and compression

- CETCO Energy: Offers water treatment processes and technologies to remove oil, hydrocarbons, heavy metals, solids, toxic materials, and other contaminants from operations wastewater stream

- SLB: Offers water treatment systems for comprehensive management of produced water, seawater, and wastewater

- Aquatech International: Offers fully integrated automated systems that produce and outlet high-purity distillate; these systems can also be used as high-purity distillate for the steam generator plant for EOR

- Veolia: Offers a broad range of solutions for produced water treatment

- Siemens: Offers primary, secondary, and tertiary treatment methods for produced water with options to discharge or reuse

Opportunities and Challenges

- The continuous growth of the world population poses a significant challenge to the drinking water supply. Apart from this, applications such as agriculture and energy production contribute to the increase use of freshwater, while contaminating the already scarce freshwater resource.

- Effluent streams are now considered as a valuable resource. This supply deficit can be fulfilled by the large quantity of produced water generated from oil & gas production worldwide for a large number of end uses, including potable consumption.

- Potable reuse of produced water faces similar challenges to other types of wastewater. These challenges include high treatment cost, potential chronic toxicity of the treated produced water, and public acceptance. Additionally, the amount and properties of the produced water change over time, making a “one size fits all” solution unlikely.

- The most significant barrier for reuse in domestic applications is public acceptance. Although existing technologies have been demonstrated to meet current drinking water standards, there are concerns about unknown toxic effects or unknown toxic compounds.

- Until the human health impact of chemical mixtures is better understood, toxicity assays are necessary to address concerns on the potential synergy between toxic compounds and the possibility of undetected toxic compounds in the treated produced water.