Sustainable Packaging – Personal Care Industry

Chemicals & Materials

Chemicals & Materials

Introduction

Overview of Sustainability in the Packaging Industry

Background: Packaging as the term denotes is a method of containing or storing the finished goods or products. Though packaging itself is not the mainstream product, businesses heavily depend on the kind of packaging it adopts for their product. There has been a long recorded history of the evolution of the packaging industry. Leaves, wood barks, and other naturally occurring materials were used as packaging materials during the middle ages. Gradually, as the industrial revolution began in the late 1750s, packaging methods and materials changed as well. This, in turn, created a high demand for packaging owing to the increased production of goods and transportation requirements. After World War-II, the packaging sector was disrupted by the use of plastics and aluminum foil. This provided the convenience of single-use and throw-away packaging, especially for Fast Moving Consumer Goods (FMCG) products.

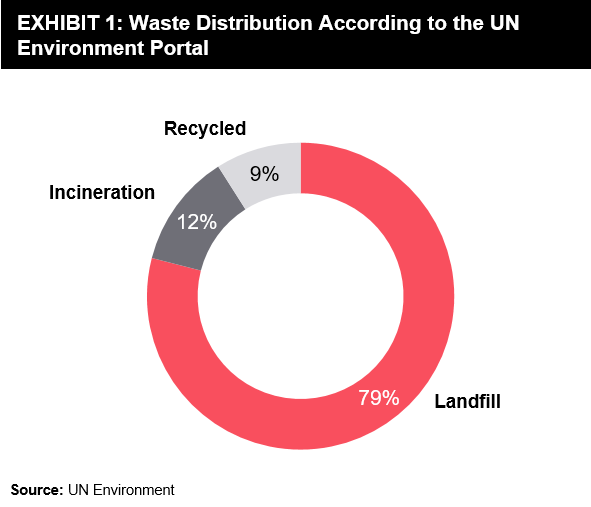

Current scenario and the need for sustainable packaging: Over the past two decades, plastics have dominated the packaging industry due to their ease of use and reliability. However, the use of plastics has left an irrevocable and damaging impact on the environment. It has been estimated that more than 8.3 billion tons of plastics have been produced since the 1950s, of which only 9% was recycled and 12% incinerated1. Over 70-80% of the single-use plastics get accumulated in landfills, thereby polluting the land. With growing awareness of the hazardous impact caused by using single-use plastics, sustainability surfaced in the packaging space in the late 2000s with a need to address the environmental footprint. If the below-mentioned criteria are fulfilled, the packaging is considered sustainable.

- Meets market criteria for performance and cost

- Is sourced, manufactured, and recycled using renewable energy

- Is produced using the best industrial practice that does not leave an ecological footprint

- Is produced with materials that can be recycled or shall be bio-decomposable after single-use

- Shall be effectively recovered using biological/industrial closed-loop cycles.

Indicators & Metrics for Assessing Packaging Sustainability

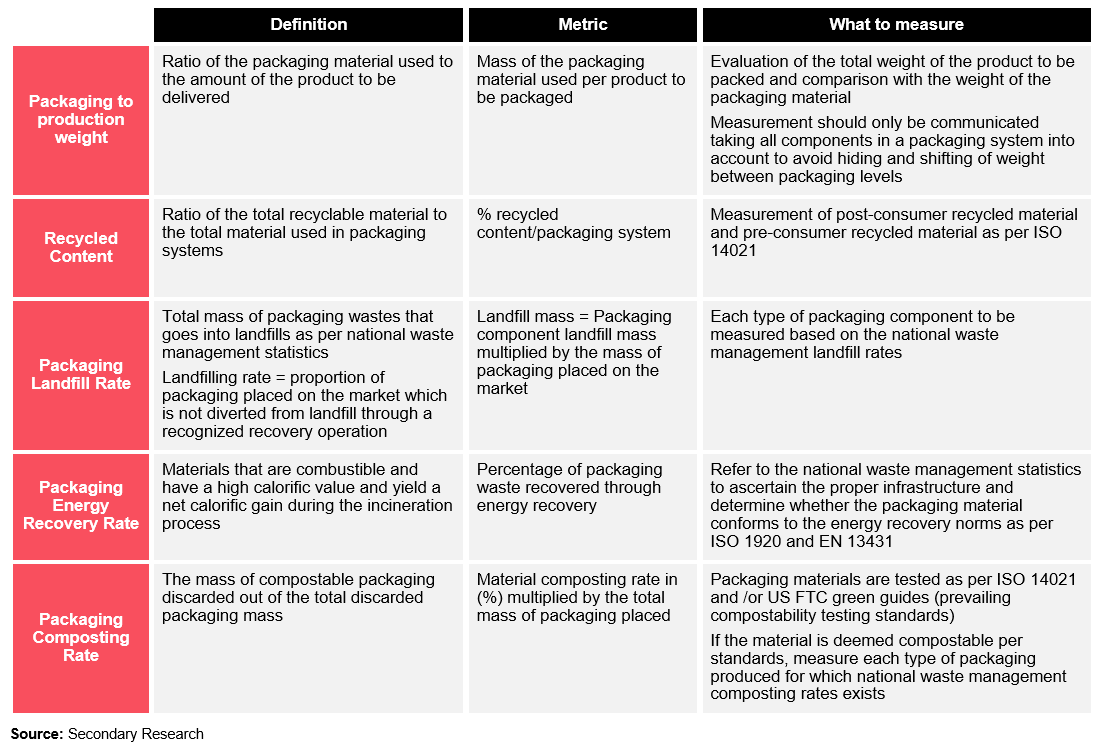

Indicators are key pointers that may express a positive or negative movement towards the stated goal. There may be several indicators to ascertain whether the packaging is sustainable or not. These indicators allow stakeholders to understand the status of their packaging models and establish baselines for their future initiatives.2 The Global Protocol on Packaging Sustainability (GPPS) provides over 40 different sustainable packaging indicators and metrics that span material use, water use, energy use, clean production, transport, cost, and performance, among other areas, which impact the value chain. Some of the commonly used indicators primarily pertain to the eco-friendly friendly aspects of packaging and the recoverability after its use. A few of the critical indicators for sustainable packaging are illustrated below:

As stated above are some of the mainstream indicators in the packaging industry. However, there may be several other indicators based on case-to-case business needs, which stakeholders are required to address prior to undertaking business decisions.

Emerging Start-Ups & New Packaging Materials

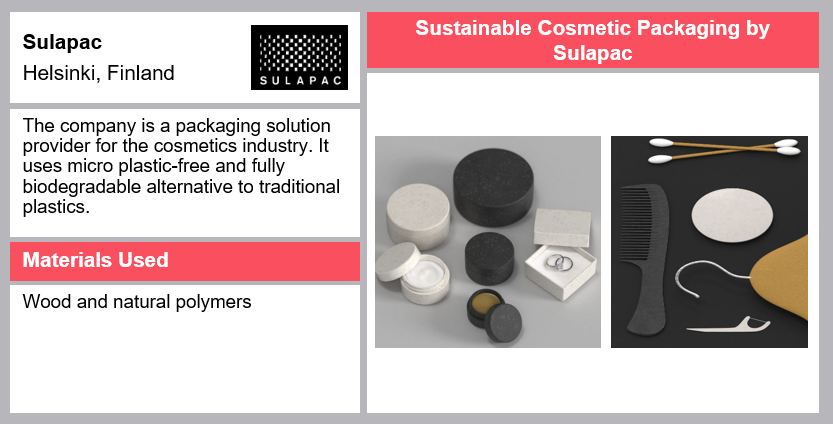

Apart from the prevalent recycling and closed-loop mechanism to keep up with the demands of sustainable packaging, there is a steady increase in the development of innovative materials that may be an alternative to conventional materials used in packaging. Some of the trending alternatives are eco-friendly packaging materials, which are compostable and renewable and leave zero ecological footprints.

The innovation of Packaging Materials in Existing Companies

Sustainable packaging may pose a challenge, as there are myriad parameters and regulations to be implemented that can have cost and time implications on mid-level and small manufacturing companies. The need for recycling shall be circumvented by investing smartly on the research and development of eco-friendly materials. Nowadays, several existing companies have invested in research and have been successful in implementing the much-needed change in materials. Some of the new materials innovated by existing companies are illustrated below:

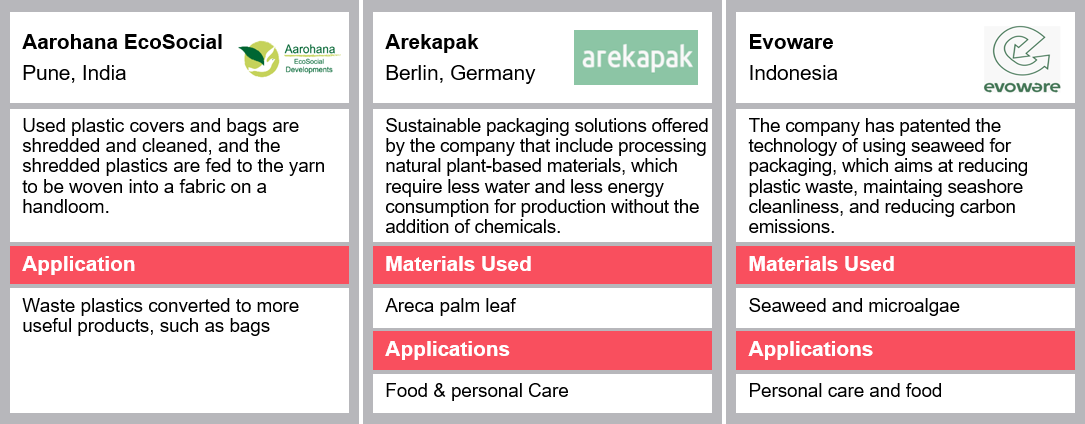

Emerging Start-Ups

The awareness, as well as the demand for sustainable and eco-friendly packaging solutions, is increasing among consumers; this rising demand can be fulfilled by start-ups addressing various possibilities of developing sustainable solutions. There are several start-ups that address the need for disruptive packaging materials with zero waste, which leave no ecological footprint. Additionally, some start-ups focus on implementing sustainable solutions by various processes, such as recovering the total energy of the packaging waste by incineration or recycling the packaging waste in a manner that leaves no ecological footprint. Several start-ups have emerged successfully across the globe in this effort. A few start-ups using sustainable packaging solutions are listed below.

Key Challenges in Adoption of Sustainable Packaging

Transitioning to sustainable packaging needs careful consideration, as the process and regulations are much more elaborate with regard to its implementation. There are several challenges ahead of the successful implementation of sustainable packaging. A few of the mainstream/key challenges are illustrated below.

Disruption in the Supply Chain

Packaging affects the entire supply chain right from the raw material manufacturer or procurer to the waste collector and the recycler and back to the material supplier again. Arising complexities due to the frequent change in government norms and regulations regarding the use of packaging materials make the adoption of new processes or changes in business models much more cumbersome to the whole supply chain.

According to Tracy Sutton, circular economy packaging design consultant at Root, “some companies are nervous about committing to purchase new materials or invest in the development of a new piece of packaging when they do not know how successful it is going to be.” This shows a mindset issue in the industry towards sustainable packaging.

Stringent Government Regulations & Lack of Administration

In several developed countries, waste collection and recycling are not monitored and coordinated centrally, which lead to inconsistency in waste management. The problem is much more challenging in developing nations, where pollution is far worse, and recycling is far less advanced.

Product Safety

The transition to sustainable packaging solutions paves the way for the use of new packaging materials. However, concerns regarding product safety and cost make consumers uncertain and unwilling to adopt such materials. In addition, there are several regulations in the food industry concerning the use of appropriate packaging materials. Moreover, these materials need to be developed in such a way that they are suitable for packaged food items.

Total Packaging Cost

As for any business to adopt change, there will always be a cost implication appended to it. With the increasing demand for the adoption of sustainable packaging, companies are facing a surge in their packaging costs. This is due to the chain effect of costs being added for the exhaustive processing and recycling of used virgin materials.

Future Prospect

The global use of traditional packaging materials has left a huge ecological footprint in terms of unrecovered plastics and non-decomposable materials dispatched to the landfills, thereby polluting the ecology. With increasing awareness and the rising need for eco-friendly solutions in the packaging domain, packaging industries across the globe are aiming to establish themselves in the domain of innovative packaging solutions. Between 2005 and 2017, there has been a steady increase in start-ups providing different approaches for sustainable packaging. Reduction of total energy consumption, recycling using renewable energy, and recovering energy by incinerating the wastes are considered mainstream approaches. Moreover, investment prospects are quite promising as several companies are investing in research programs for the adoption of new packaging materials that can replace the traditional ones.

The concept of the circular economy is gaining momentum with the adoption of sustainable packaging solutions. As the name implies, the goal of the circular economy is to make the whole supply chain of the packaging industry a continuous loop, where packaging materials shall be reused or regenerated into new products. By this, the value of the product gained its maximum, and the overall life of the product can be extended.

The future of the packaging business lies in strategic collaboration. Mid-level manufacturers are undertaking efforts to collaborate with start-ups to implement innovative packaging ideas and develop profitable business strategies.

7 min read

7 min read