Enabling an EV OEM to build a Li-Ion Electrolyte Manufacturing Capability

Listen to this Article

mins | This voice is AI generated.

mins | This voice is AI generated.

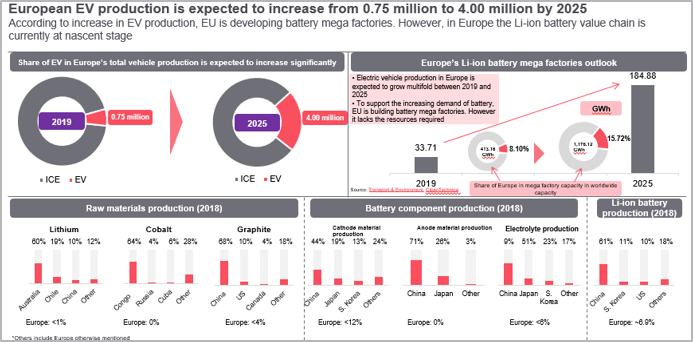

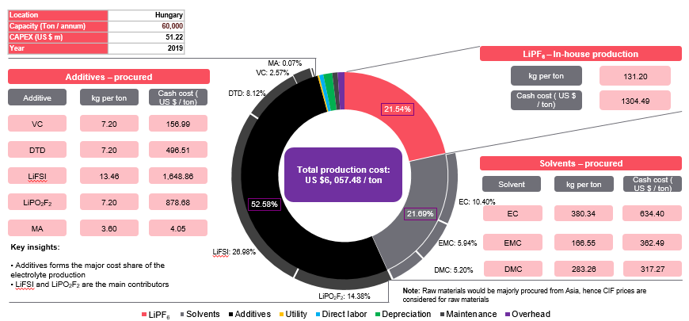

Our client specializes in electric and battery-powered passenger vehicles. They needed our help to develop a manufacturing strategy that could help them to build their own battery manufacturing capability in Europe. Our client needed to understand the manufacturing economics of Li-ion electrolyte and its components (LiPF6 salt, solvents and additives).

With our help, our client was able to understand the market structure, manufacturing economics of Li-ion battery electrolyte and its components. FutureBridge answered several strategic questions including:

Li-Ion batteries are the main core of the electric vehicle segment and developing manufacturing capability is very important to gain competitive advantages.

Li-Ion batteries are the main core of the electric vehicle segment and developing manufacturing capability is very important to gain competitive advantages.

FutureBridge conducted extensive primary and secondary research across the Li-Ion battery value chain in different regions. Primary research included interviews with major additives, solvents, LIPF6, and electrolyte manufacturers and industry experts to assess the manufacturing economics of electrolyte & its components.

FutureBridge further analyzed current industry activities, proposals, and the plans of key players, plus various related technical, commercial, and regulatory factors to understand the future of the Li-Ion battery value chain. The manufacturing cost analysis of each additive and LiPF6 salt was done. The work FutureBridge carried out enabled our clients to define their business plan and operational roadmaps.

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur long-standing clients include some of the worlds leading brands and forward-thinking corporations.