Battery Materials – 2025 and beyond

Listen to this Article

mins | This voice is AI generated.

mins | This voice is AI generated.

The global energy demand has risen multi-fold over the decades. The pressing concern to supply energy all over the globe and to reduce the climate change impact caused by fossil fuels becomes the need of the hour to switch to reliable green energy with a suitable energy storage technology such as batteries.

As a state-of-the-art storage system, battery finds its major applications in sectors like consumer electronic goods, stationary and portable energy storage systems, grid energy, automotive sector, etc. Moreover, the global corporate and government mandates have been the proponents fostering the electrification of the mobility sector through their initiatives, regulatory policies, and regulations. As a result, these industries are now witnessing a prominent shift from energy rigorous to material-intensive systems.

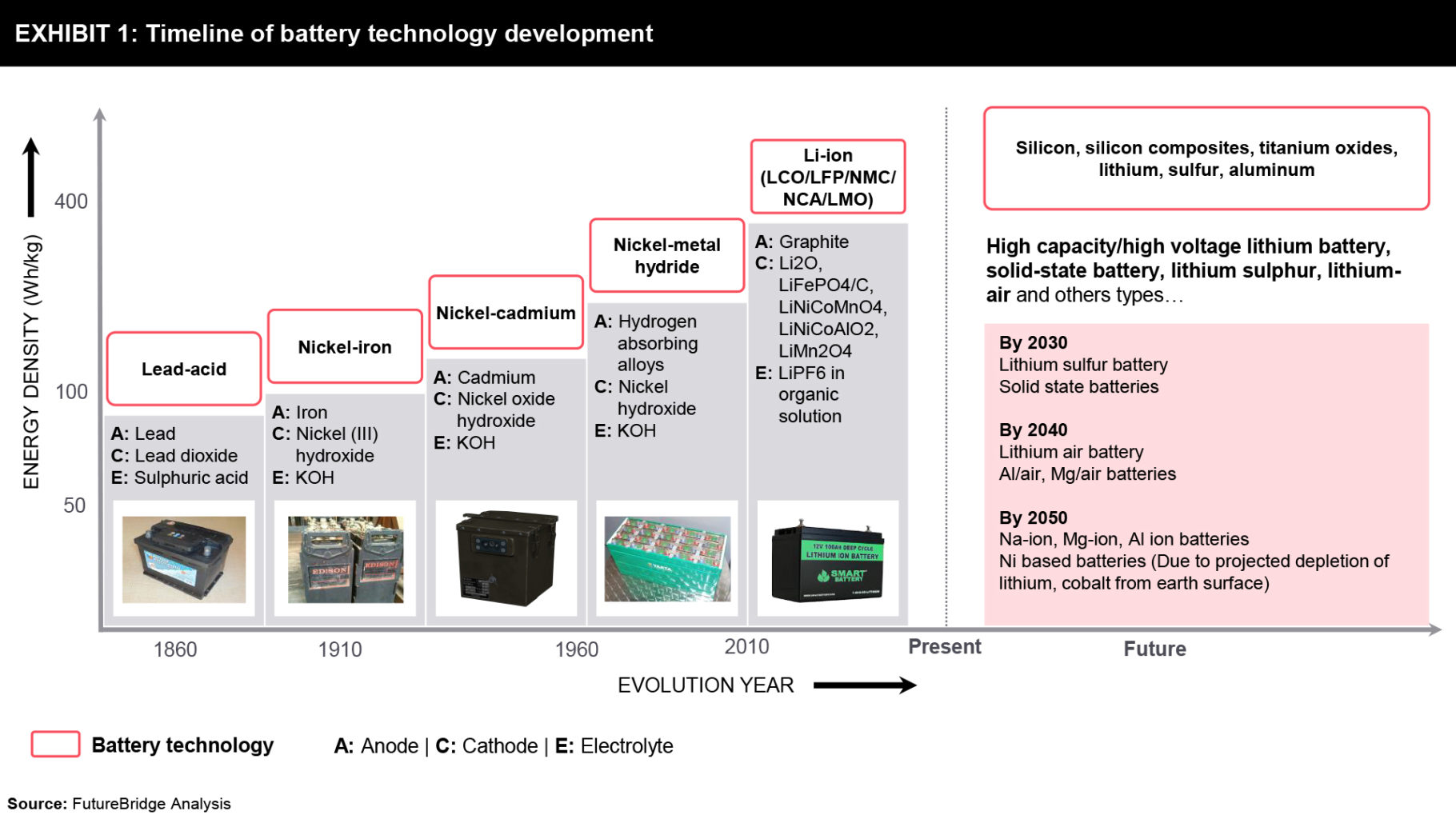

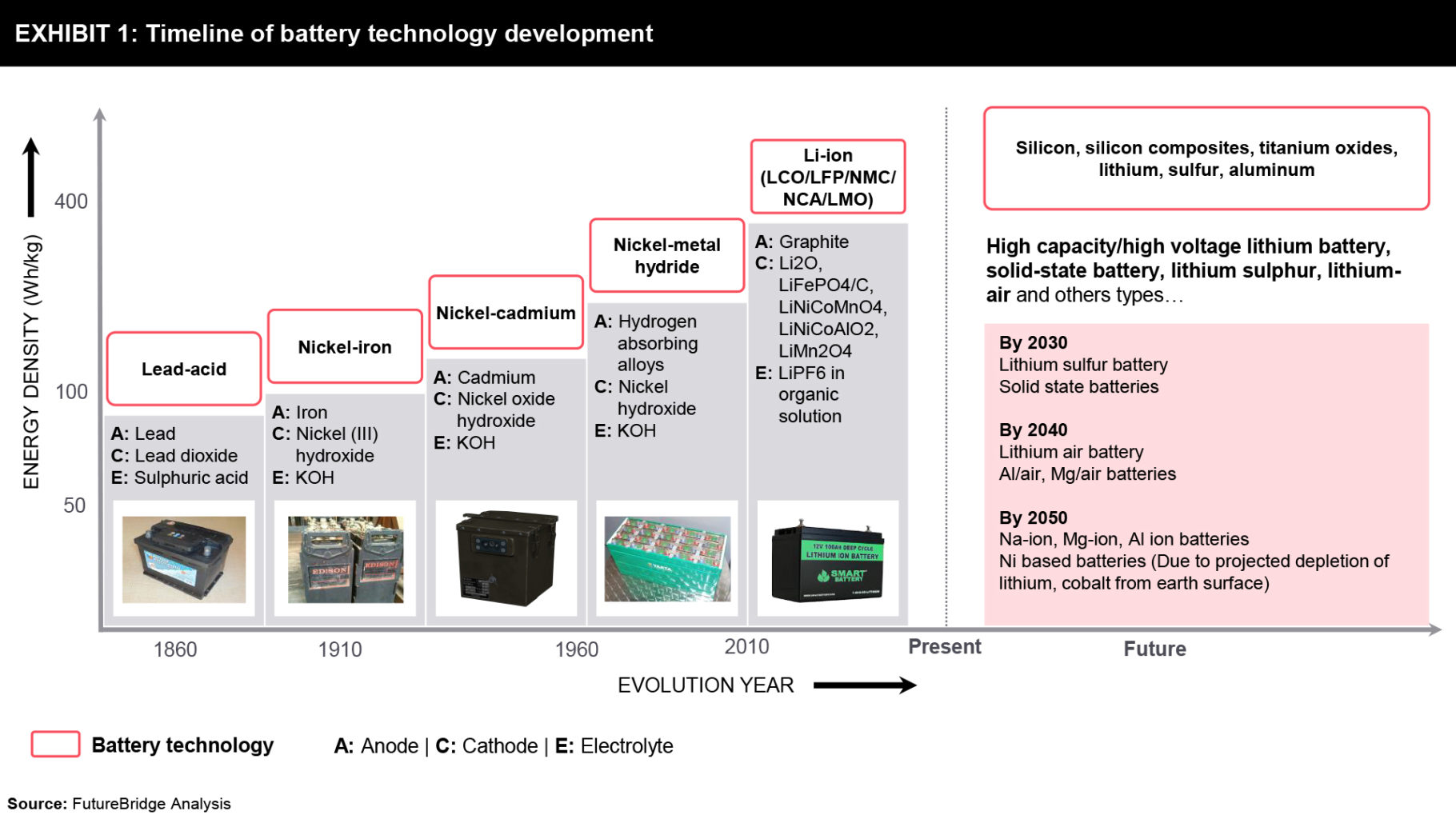

Apart from the well-established and quite aged lead-acid batteries, LIB (Lithium-ion battery) is currently widespread among all other battery types, with its application ranging from smartphones to electric vehicles. The current LIB technologies in use are NMC oxide batteries, lithium manganese oxide batteries, lithium NCA oxide batteries, lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium titanate batteries. Among them, lithium nickel cobalt aluminum oxide is found to possess the highest specific energy density of 200 – 250 Wh/Kg and is relatively cheap at the same time, whereas lithium titanate exhibits a soaring life cycle of 3000 – 7000. This is a reason for the EV market leader Tesla to employ lithium NCA/NMC battery to get a better edge over its competitors, which intends to replace costly metals like cobalt with nickel-based chemistries. Exhibit 1 gives us an overview of the timeline of the development of various kinds of battery technologies over years and potential future battery materials.

Although each battery has its own advantage and disadvantages, high energy storing potential, shorter charging time, improved cycle life are the main advantages of LIB. The main challenge faced in using LIB is that their lifecycle and performance curves decline at elevated temperatures which raises substantial safety concerns over its usage in EV and electronic gadgets. Moreover, the abundance of lithium in the earth’s crust is only 0.002% – 0.006%, and also this battery technology makes use of Nickel and Cobalt which are other critical elements on earth. Therefore the world automotive production leaders are expected to face the crisis of cobalt and lithium shortage due to geopolitical reasons.

Owing to this scenario, various corporates and institutes have collaboratively engaged to innovate on battery materials as per battery technology to cater to future energy demand and certain critical material crises.

The prolonged stagnant periods of battery technology development have seen significant cutting edge breakthroughs in the recent past. The technology drift from heavy lead-acid batteries to more compact, sustainable, efficient battery technologies is imminent. The state-of-the-art LIB stands as one most significant groundbreaking technology in the energy sector. Also, we are in the imminent stage and about to witness disruptive technologies employing more sustainable materials for their operation in the post-lithium era.

Innovation in battery technologies

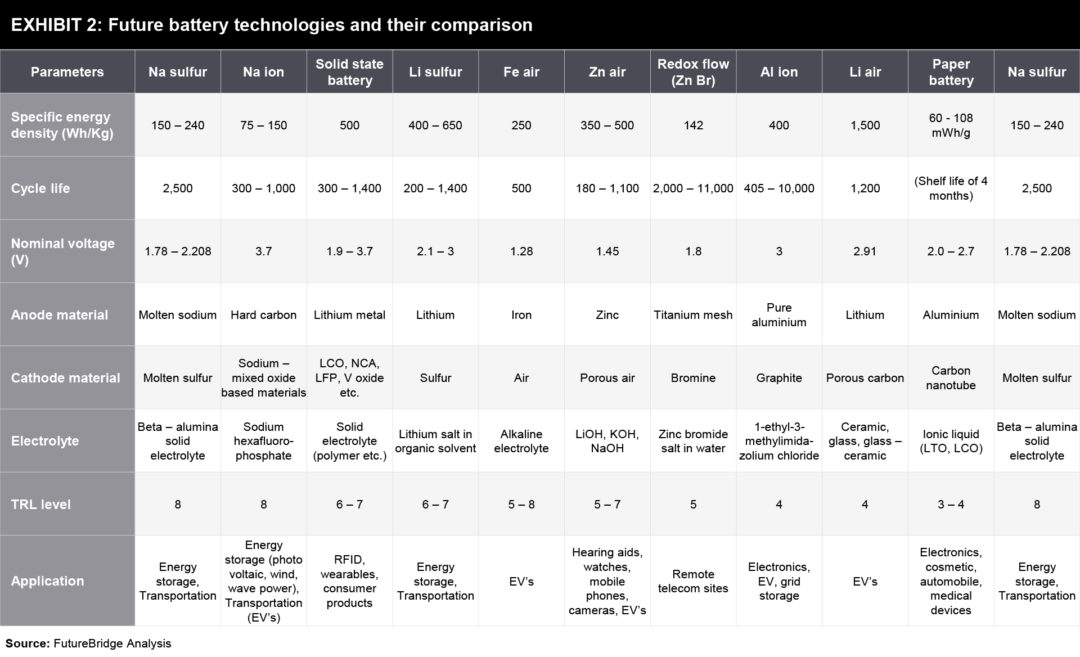

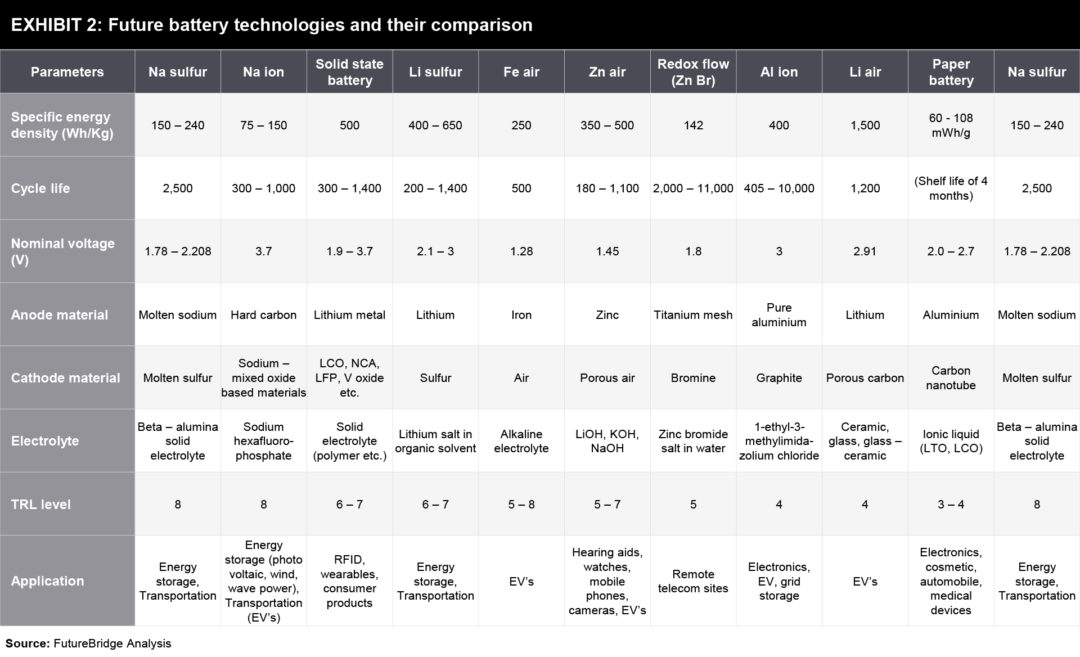

There have been immense battery-related technology innovations for over a decade. The top five most researched battery types based on the patents filed are flow batteries, solid-state batteries (Na, Li based), sodium ion, lithium sulphur, and zinc-air battery. Apart from these, there are various other innovative battery types such as solid-state batteries, flexible batteries, paper batteries, etc. Exhibit 2 shows us the comparison of various future battery technologies to be commercialized in the next few decades.

Apart from the above mentioned technologies, there are various other novel battery technologies that are being conceptualized, such as cobalt-free LIB, gold nanowire batteries, graphene batteries, foam batteries, laser-powered super micro capacitors – based on the fast-charging principle are gaining more traction among the research community. However, they are still in the postulation stage and their commercialization is expected to be beyond 2040 or 2050.

Future battery materials

The demand for batteries with enhanced energy density and better safety has become a necessity to suffice the growing energy needs, and therein a strong pursuit for green chemistry and efficient battery materials has begun. The key existing battery materials used currently are mentioned in this article. Also, the emerging battery materials for next-generation battery technologies to achieve our sustainable development goals are discussed in this section.

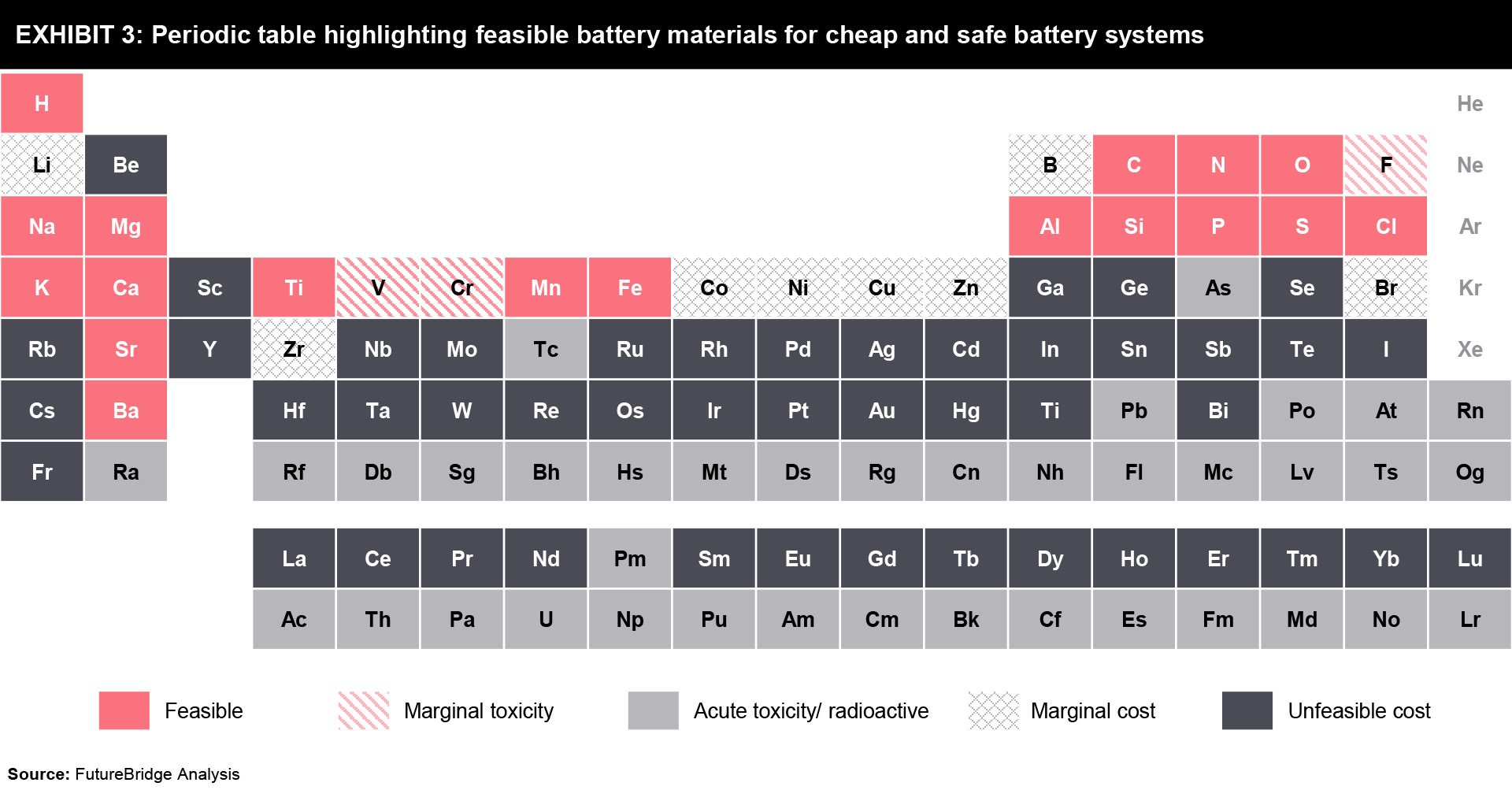

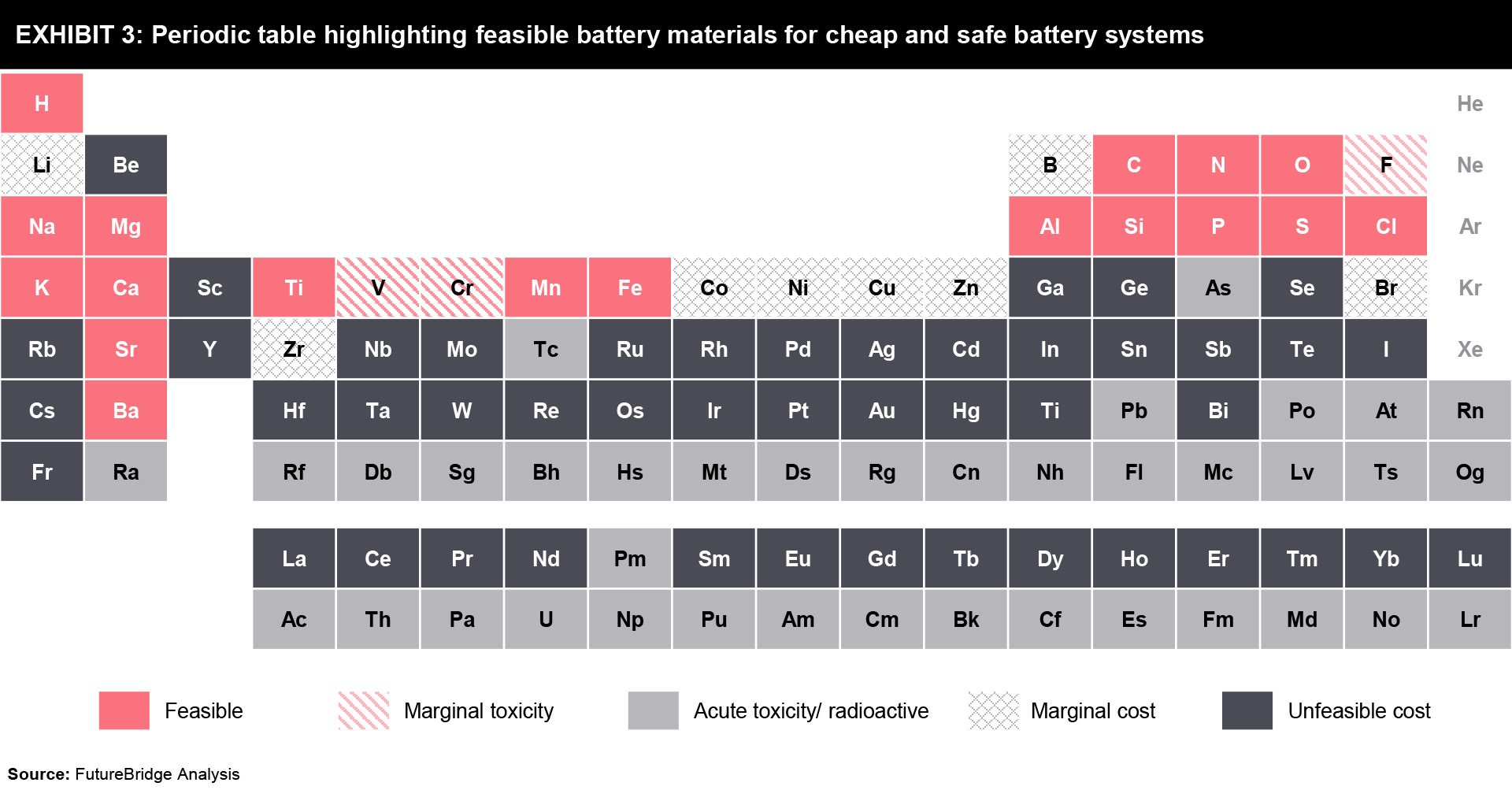

Apart from the above-mentioned materials, the periodic chart gives us a clear depiction of the feasible future battery materials which are very likely to rule the energy storage market in the upcoming decades. Among these, silicon is the most researched anode material possessing ten times larger energy density than conventional graphite anode, has also gained an edge over its counterpart in the sustainability aspect since the former can be derived from plant-based sources like barley husk ash. An overview of various potential elements/ materials to be used in future battery technologies is shown in Exhibit 3.

Investment activities in the battery technology domain

The global market investment for advanced battery materials is projected to reach US $110 billion by 2024. There have been wide commercial activities in battery technology, material innovation domains in the past decades. A few major activities in recent times are as mentioned below:

Conclusion

The energy technology companies are constantly striving to enhance the sustainability feature of batteries through various avenues. The critical properties which will play a major role in deciding the promising battery candidates are raw material abundancy, cost competency, energy density, emission toxicity, durability, operational efficiency.

The state-of-the-art LIB batteries face certain toxicity and supply chain issues, and so, finding suitable replacement technology is of primary concern among the sustainable battery community. Although lithium-sulfur and lithium-air batteries have shown satisfactory results on a research scale, the time period for their commercialization and the energy-intensive mining step involved along with the possible depletion of lithium resources on the earth’s crust are some of its inherent setbacks.

The need to search for sustainable battery materials is of primary concern and this necessity made the industry explore different bio-based materials, for e.g.: cellulose-based materials as potential electrode binders. These continuum novel researches will help us attain our sustainable goal, at the same time not compromising on the battery performance.

On a concluding note, until various potential battery technologies and battery materials are in the nascent conceptual stage, it is important that existing materials and battery designs are engineered to provide high battery capacity and energy, longevity and also see that the used materials are cost-effective, abundant and recyclable in nature, so as to achieve circular economy and lead a sustainable route in the future.

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur long-standing clients include some of the worlds leading brands and forward-thinking corporations.