Engineering Tomorrow: The Growing Role of Robots in the Construction and Industrial Services Industry

Introduction

Once deemed unlikely pioneers of automation, construction and industrial services are now embracing robotics at an unprecedented pace, thanks to breakthroughs in AI, machine learning, and materials science. The future of these industries is being built—one robot at a time. From routine tasks like bricklaying to complex high-rise construction, robots are transmuting workflows and redefining new standards for productivity, efficiency, and safety. In this article, we assess how robots are reshaping these sectors and the future potential they hold.

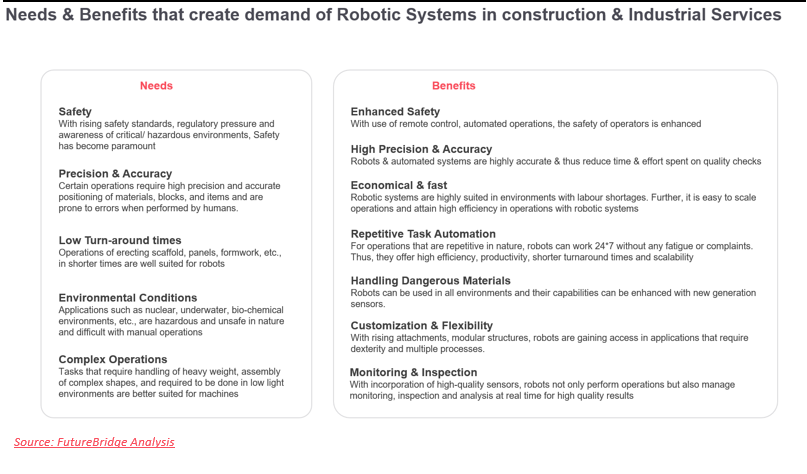

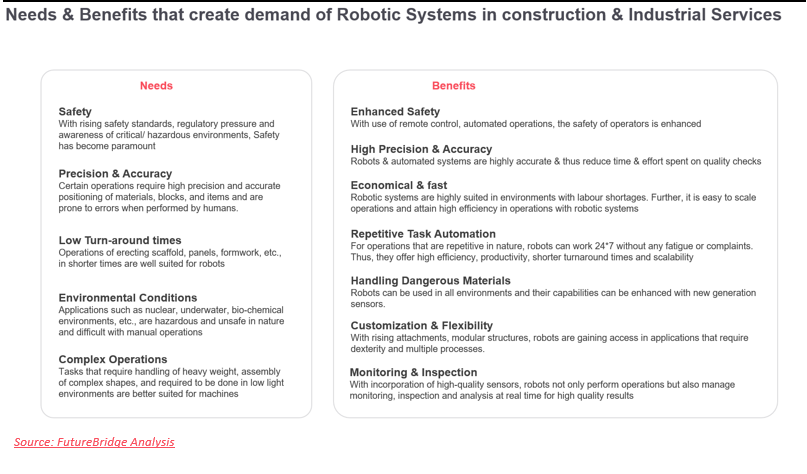

To better understand the rise of robotics in these industries, let’s explore the specific needs of these sectors and the unique advantages that robots bring to the table.

Having explored the needs and benefits of robotics in construction and industrial services, the next logical question is: what are the key applications where robots are making an impact? Let’s take a closer look at some prominent areas in these industries where robots are leading the way.

Construction Applications:

- Bricklaying

- Masonry

- Concrete pouring and finishing

- Demolition

- Site mapping and planning

- Tile installation

- Underground and hazardous site exploration

- Foundation drilling and pile driving

- Assembly of prefabricated modules

- Material transport

- Autonomous surveying, etc.

Industrial Services Applications:

- Welding

- Painting, Coating, and Surface Finishing

- Assembly line operations

- Fastening and Assembling

- Inspection, Testing, and Quality control

- HVAC installation

- Prototyping and Custom manufacturing

Robots are now utilized across various stages of these processes, with their capabilities expanding and new services emerging every quarter.

Evolution of Robots in Construction Industry

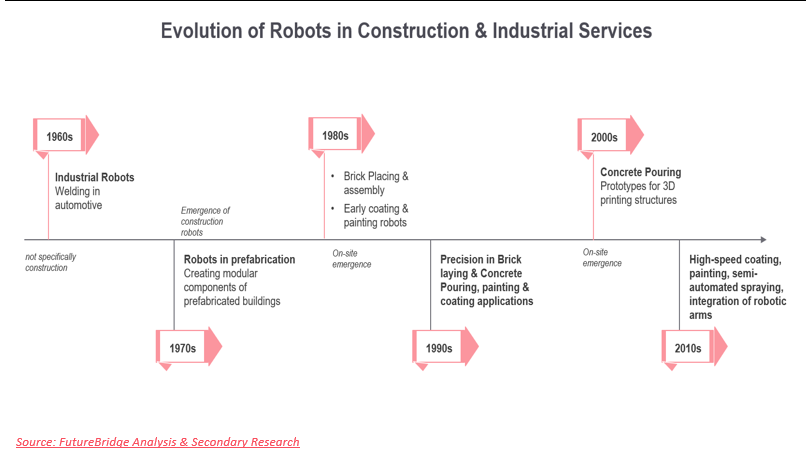

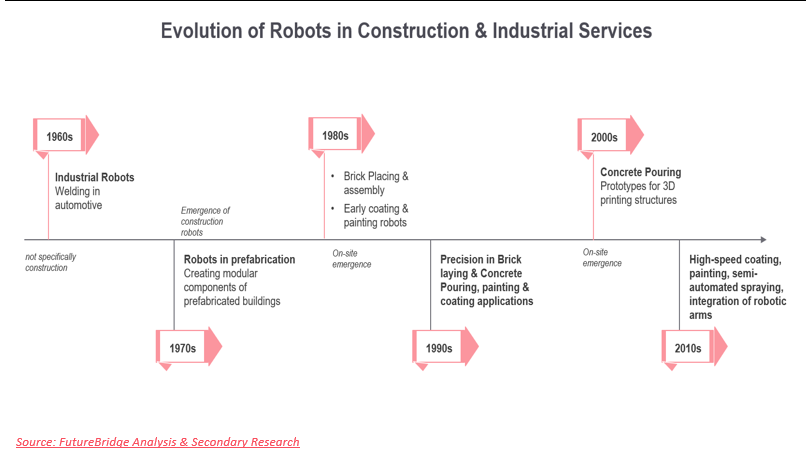

The evolution of robotics in construction and industrial services has been transformative. It began in the 1960s with the introduction of Unimate, the world’s first industrial robot, which revolutionized manufacturing by automating repetitive tasks like welding and material handling. However, these early robots were limited in scope and flexibility.

In the following decades, advancements in technology-enabled robotics to impact construction. Robots were initially used for tasks like bricklaying and assembling prefabricated modules. By the 1990s, their applications expanded to include concrete pouring, painting, coating, and spraying.

The 2000s marked a turning point with the introduction of advanced automation, sensing technology, and remote-control capabilities. By 2010, robots were actively used in high-rise construction, prefabrication, demolition, and welding, driven by the need for increased efficiency, safety, and the ability to operate in hazardous environments. Despite these advances, robotics were not yet widespread in construction, and many tasks remained manual.

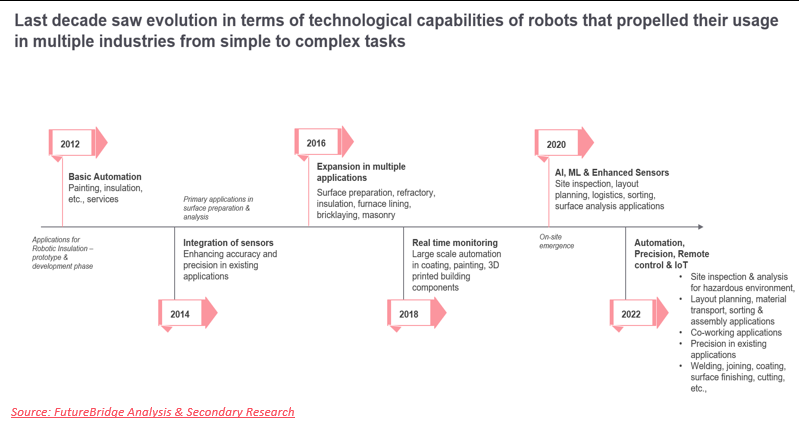

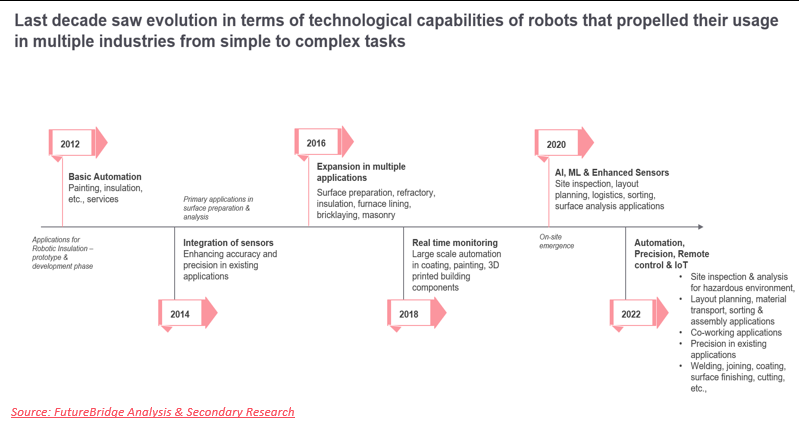

Transformational Decade for Robots (2012 -2022)

The past decade has marked a dramatic shift in robotics, fueled by advancements in AI, machine learning, materials science, sensors, and data processing. These innovations have accelerated the adoption of robotics in construction and industrial services, enabling them to take on more complex tasks.

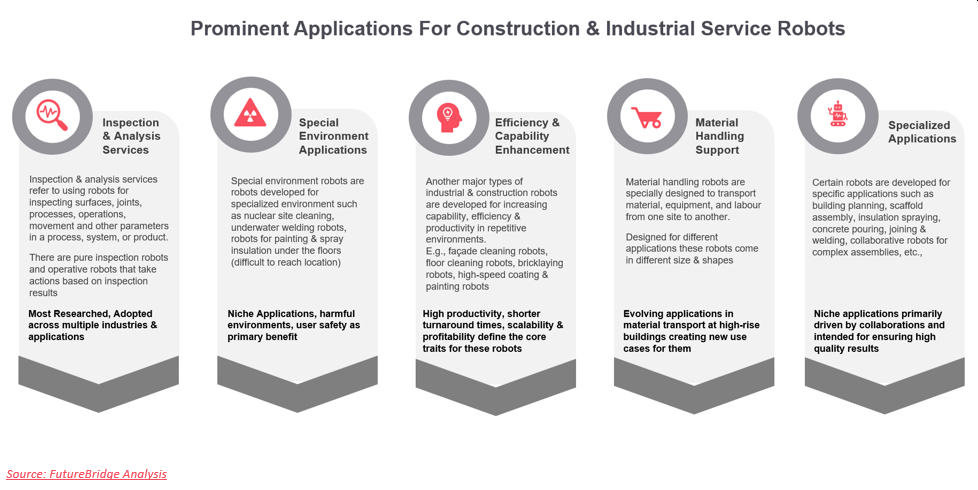

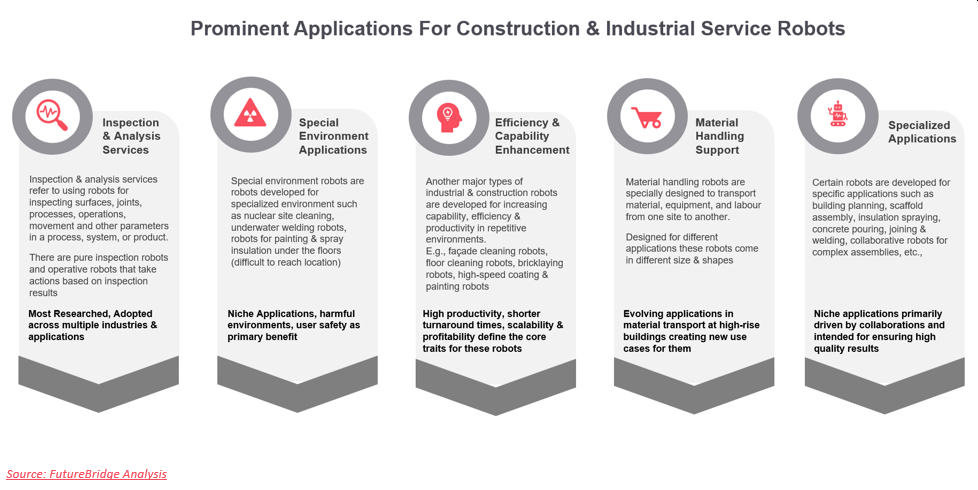

Robots have expanded their roles to include inspection, data acquisition, monitoring, and automating intricate processes like underwater welding, precision cutting, and non-destructive testing. They now play key roles in waste disposal, material transport, hoisting systems, scaffold assembly, and even co-working with humans on challenging tasks.

Today, robots are integral to both sectors, handling everything from autonomous material transport and precision painting to 3D printing entire structures and conducting real-time site inspections with drones. Thanks to the integration of AI, machine learning, and the Internet of Things (IoT), these robots have evolved from simple tools to intelligent collaborators capable of adapting to dynamic environments.

Looking ahead, the potential for robotics in construction and industrial services is limitless. Imagine robots autonomously constructing skyscrapers using adaptive 3D printing, or human-robot teams seamlessly integrating with augmented reality to enhance real-time collaboration. As technology advances, robotics will continue to drive smarter, more sustainable, and efficient processes in these industries.

The evolution of construction robotics is remarkable. Before 2010, they were limited to automating simple, repetitive tasks. Post-2010, advancements in sensors, computational power, and analytics enabled robotics to take on complex and critical applications. Today, these machines are integral to construction, handling everything from routine operations to advanced tasks like inspection, material handling, and autonomous construction, reshaping industry practices.

Evolving Landscape of Construction and Industrial Robotics

Understanding the current state of robots in construction and industrial services requires consideration of two key factors:

- Prominent Applications of Robots Today

- Construction and Industrial Robots Ecosystem

Prominent Applications of Robots in Construction & Industrial services-sectors in Current Times

Construction and Industrial Robots Ecosystem

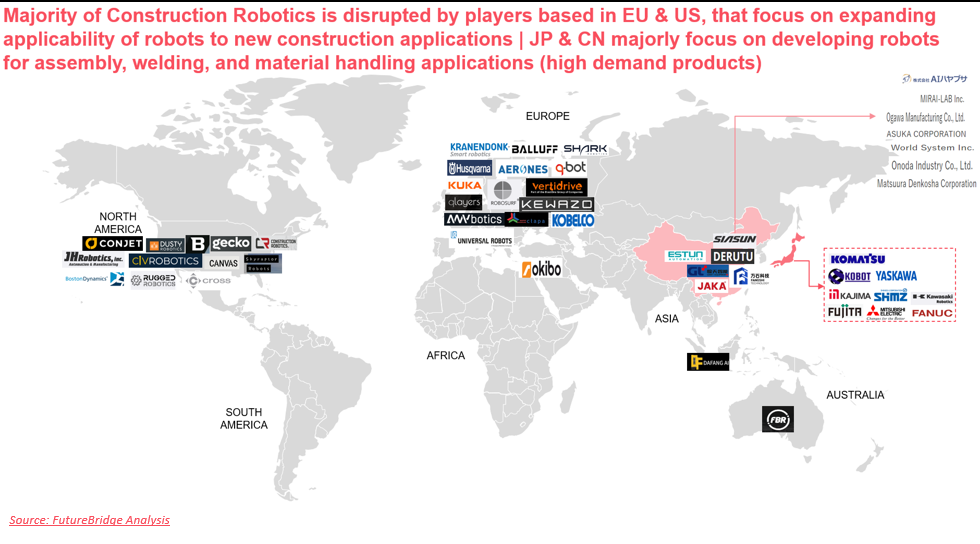

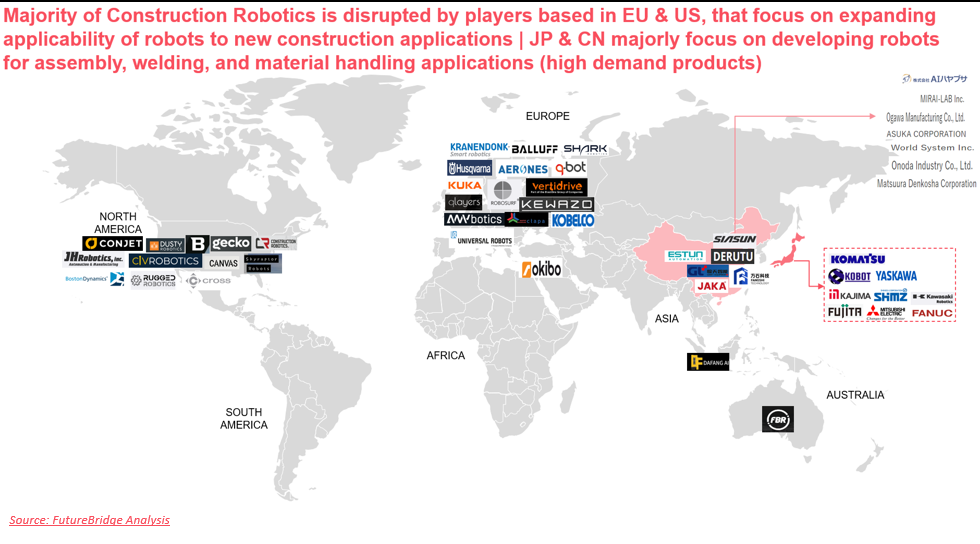

Unlike the production robot market, dominated by China and Japan, the construction and industrial services robot market remains niche, with global players actively involved. Companies from the US, Europe, Korea, Japan, and China are driving automation in specific construction and industrial processes, with a focus on research, development, and specialized production.

Most innovations in this field are collaborative, involving manufacturers, customers, and large corporations investing in technologies after successful prototype testing and commercial production. Non-destructive testing, inspection, and analysis are key areas of focus for many companies in this space, with end-to-end solutions provided, including robots, components, and software.

The US and Europe are at the forefront of developments in construction robotics, with key contributions from countries like Germany, the UK, and the Netherlands driving innovation. Japan and China are also significant contributors, with Japan focusing on labor-saving automation for large projects, and China concentrating on creating custom machinery for global markets.

The Rise of Robotics in Construction and Industrial Services

Robotics in construction and industrial services has advanced rapidly, fueled by breakthroughs in AI, machine learning, and materials science. Once limited to basic tasks like bricklaying and welding, robots now excel in complex operations such as inspections, material transport, and hazardous environment applications. These innovations have redefined efficiency, safety, and productivity across industries.

Although still a niche market, global players from the US, Europe, Japan, and China are pushing the boundaries with specialized applications like non-destructive testing and advanced automation. Collaboration between manufacturers, tech startups, and corporations is driving continuous innovation, setting the stage for smarter, more efficient processes.

Coming Up Next:

In the next and concluding series of this article, we’ll assess in detail the finer aspects of the construction robotics ecosystem, spotlighting prominent robots for various applications, their capabilities, levels of automation, adoption benefits, and the future of robotics in construction and industrial services.