Emerging Manufacturing Technologies Assessment for Float Glass

Listen to this Article

mins | This voice is AI generated.

mins | This voice is AI generated.

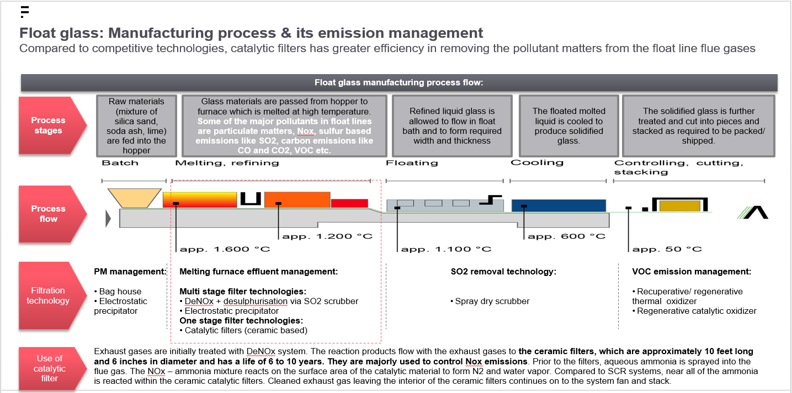

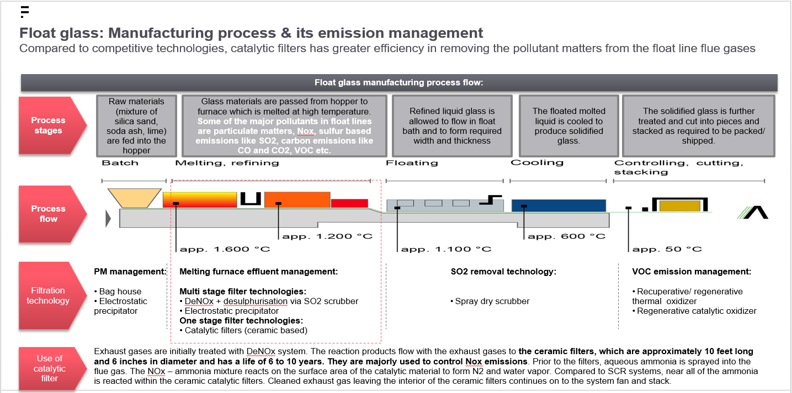

Our client specializes in float glass manufacturing & they wanted to understand the innovations in context with technologies relevant for reduction of float line emissions, improved energy efficiency, and product quality within various unit operations of float line such as furnace based melting process, fuel technology, batching, annealing, floating and final processing stage.

With our help, our client was able to understand the emerging process & energy efficient, low CO2 emission technologies used in float glass production lines.

FutureBridge was also tasked to answer our client’s critical business questions including :

Glass float line are major CO2 emitter and energy consuming industrial process. There was a need for understanding new technologies with potential to make the process more sustainable.

Glass float line are major CO2 emitter and energy consuming industrial process. There was a need for understanding new technologies with potential to make the process more sustainable.

FutureBridge conducted extensive primary and secondary research across selected companies to develop a concise view of the current and emerging float line technologies. Primary research included interviews with technology developers and industry experts to assess the upcoming melting furnace technologies, fuel technologies, digitization process, etc.

FutureBridge further analyzed current industry activities, proposals and the plans of key players, plus various related technical, commercial and regulatory factors to understand the future of float glass manufacturing process. The work FutureBridge carried out enabled our client to define their business plan and operational roadmaps to understand and adopt and look up for innovative float line manufacturing process.

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur long-standing clients include some of the worlds leading brands and forward-thinking corporations.