Optimizing Procurement of Critical Raw Materials for a European Manufacturing Client through Comprehensive Supply Chain Risk Assessment

Quick Overview

Companies often possess insights into the health of their suppliers but lack visibility into the entire upstream supply chain, leaving operations exposed to unforeseen disruptions. Our client, a European specialty additive manufacturer, encountered challenges related to key raw material availability, impacting their operations. As their trusted consulting and advisory partner, FutureBridge intervened to uncover reasons, identify risk factors, and optimize their procurement strategy by:

(i) Enhancing visibility throughout the entire upstream supply chain, encompassing 2-3 nodes backward.

(ii) Pinpointing risks associated with each node, culminating in a comprehensive assessment of the entire supply chain.

Client Success Details

At FutureBridge, we conducted a meticulous analysis to enhance visibility across supply chains. Our comprehensive approach involved:

Key chemicals, vital to the supply chain, were exclusively produced in a particular province, posing a substantial risk. The dependency on a few suppliers for these critical raw materials put the entire supply chain in jeopardy. Unfortunately, many stakeholders lacked visibility along the supply chain, leaving them unaware of this vulnerability. Key chemicals, vital to the supply chain, were exclusively produced in a particular province, posing a substantial risk. The dependency on a few suppliers for these critical raw materials put the entire supply chain in jeopardy. Unfortunately, many stakeholders lacked visibility along the supply chain, leaving them unaware of this vulnerability. |

|

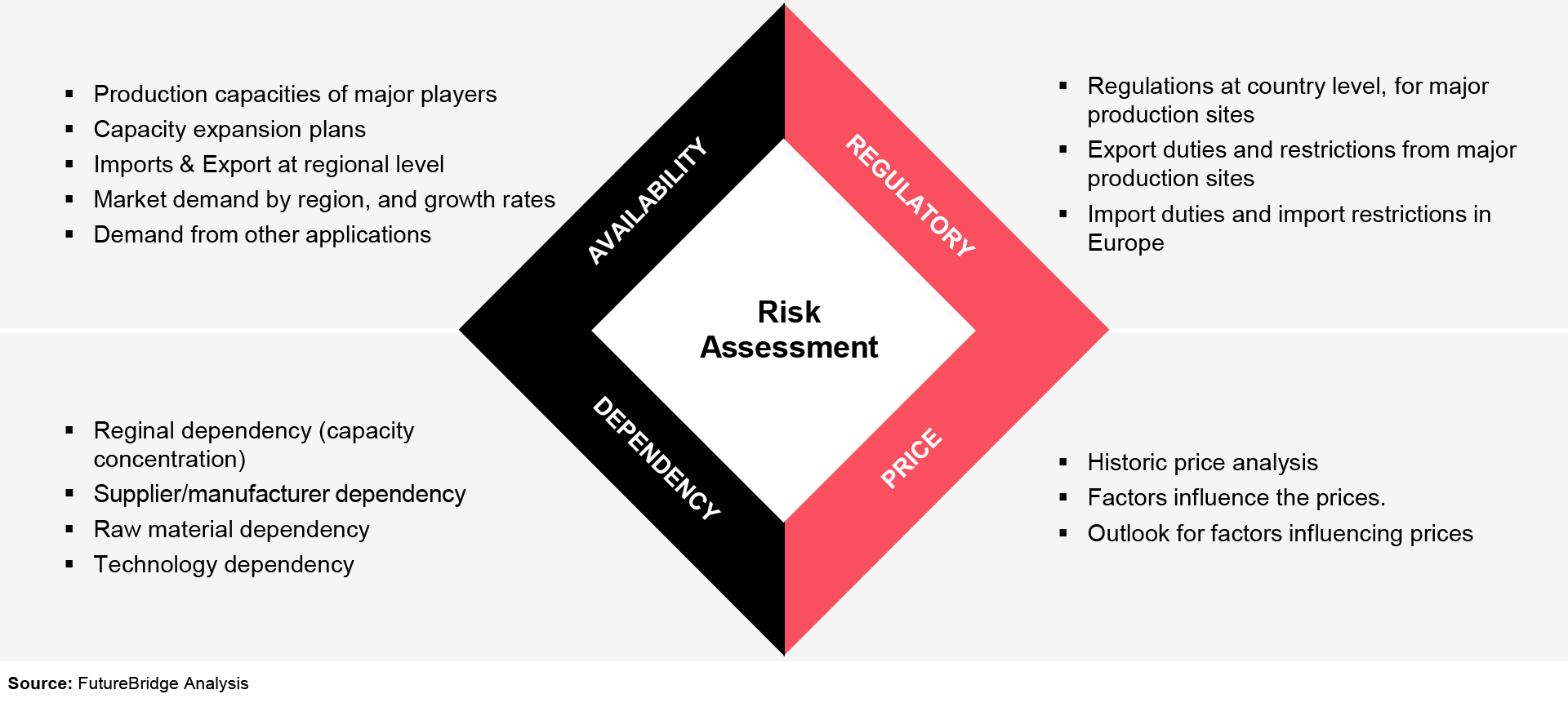

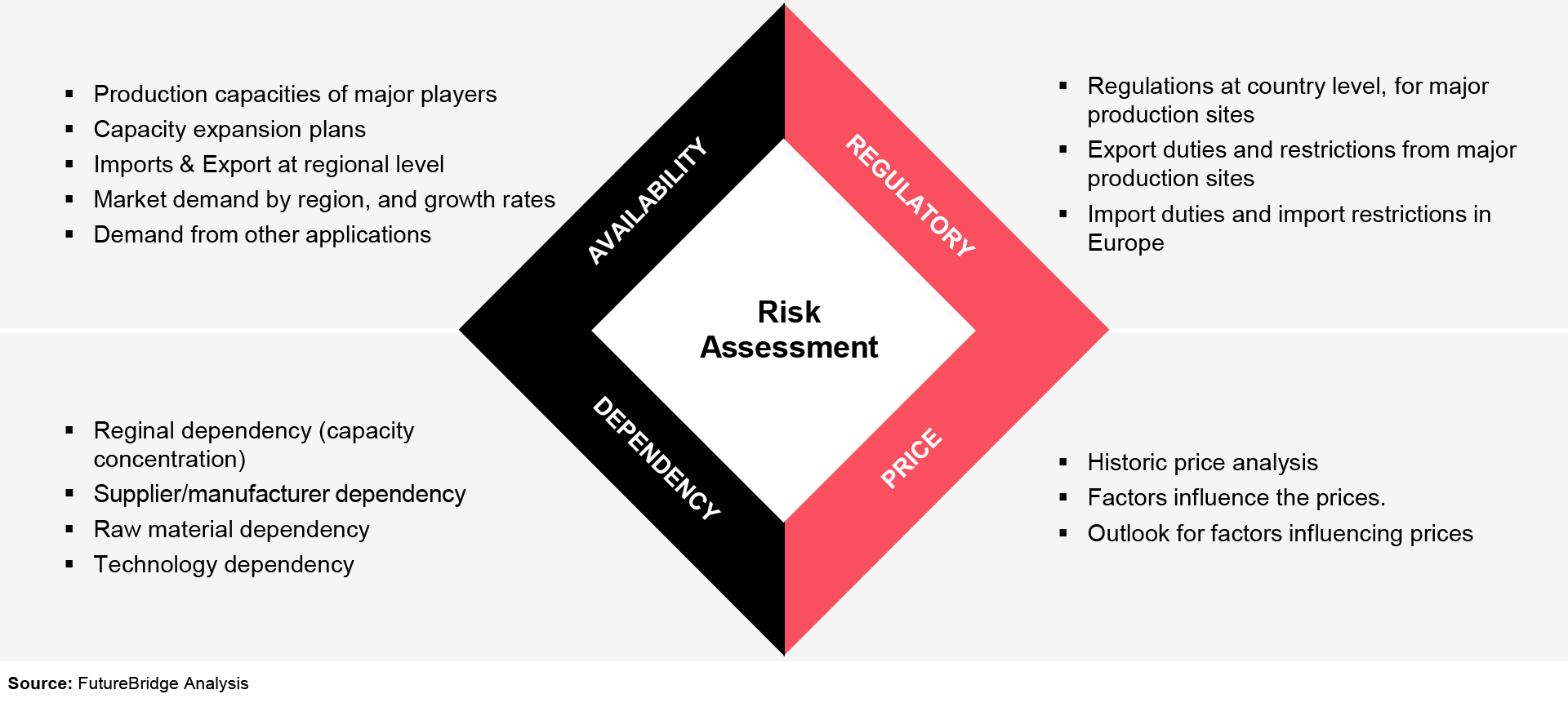

Subsequently, we performed a detailed risk assessment for each identified raw material along the supply chains. This involved evaluating various parameters across four categories to ensure:

We assigned quantified values and weightage to all parameters, providing risk scores for each raw material and the entire supply chain. The following outcomes of this engagement were significant for our client:

- Regional Dependency Confirmation: Our analysis validated concerns about regional dependency for specific raw materials.

- Nuanced Risk Understanding: A precise grasp of varying risk levels across different raw materials challenged and evolved their initial knowledge.

- Strategic Calibration: FutureBridge recommendations allowed our client to calibrate and enhance their internal supply chain strategy effectively.

The study’s findings, coupled with FutureBridge recommendations, empowered our client to calibrate and enhance their internal supply chain strategy significantly.

Connect with us to unlock transformative insights into supply chain resilience, offering quantified risk assessments and strategic calibration opportunities for enhanced sustainability.