FutureBridge Drives Recycling Innovation and Scope 3 Emissions Reduction for our Global Client

Quick Overview

Thermoset polymers, comprising 11% of global plastic production (estimated 42 million metric tonnes), are difficult to recycle because their covalent cross-linked structures prevent melting and reprocessing. Unlike thermoplastics, thermosets cannot revert to a fluid state upon heating, complicating traditional recycling methods. Hence, despite their advantages in structural applications, such as having higher dimensional stability and being lighter weight, limited recyclability results in most thermosets being landfilled or incinerated today.

Our client, a multinational polymer manufacturer with a diverse thermosetting polymer portfolio, wishes to tackle this recycling challenge via the development of circular strategies which would concurrently meet regulatory requirements and reduce Scope 3 emissions. Hence, they commissioned FutureBridge to conduct a technology horizon scan before selecting the most attractive innovations and developing the necessary strategies to implement them into their supply chains.

Client success details

The cross-linked networks of thermosets make them attractive for structural applications due to their high dimensional stability and lightweight nature, but this also limits their recyclability. FutureBridge guided our client by identifying closed-loop recycling solutions for these hard-to-recycle thermosetting polymer waste streams with the objective of integrating the recycled materials back into the virgin production line. Polymers evaluated included PUs, epoxy resins, silicon polymers and thermoset polymer composites with critical questions being asked such as:

Our goal is to align with regulatory requirements by creating an efficient waste collection system, utilizing advanced sorting methods, and adopting innovative recycling technologies to ensure that recycled thermoset polymers are seamlessly reintegrated into our production line. Our goal is to align with regulatory requirements by creating an efficient waste collection system, utilizing advanced sorting methods, and adopting innovative recycling technologies to ensure that recycled thermoset polymers are seamlessly reintegrated into our production line. |

|

With the support and advisory services provided by FutureBridge, our client identified the recycling innovations most suited to their needs and developed the strategies necessary to implement these recycling solutions into their existing supply chains.

The study addressed aspects like:

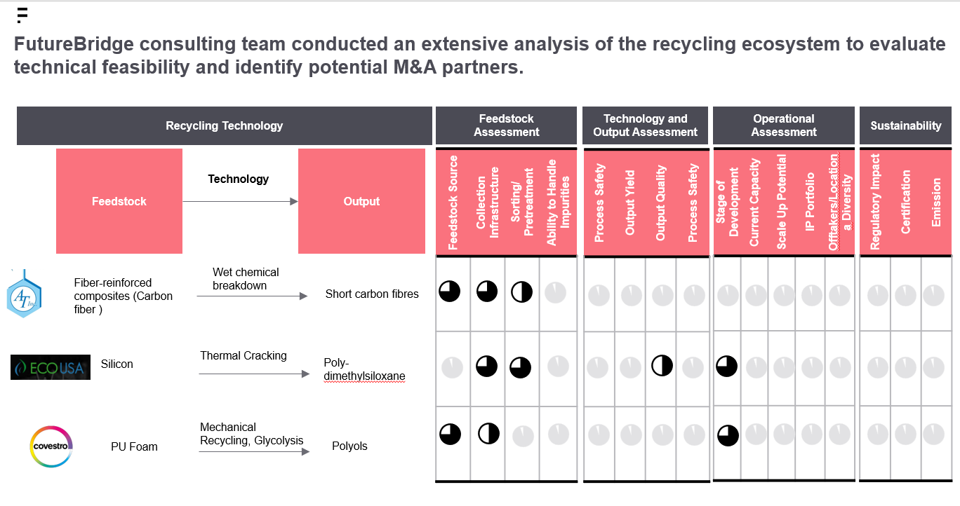

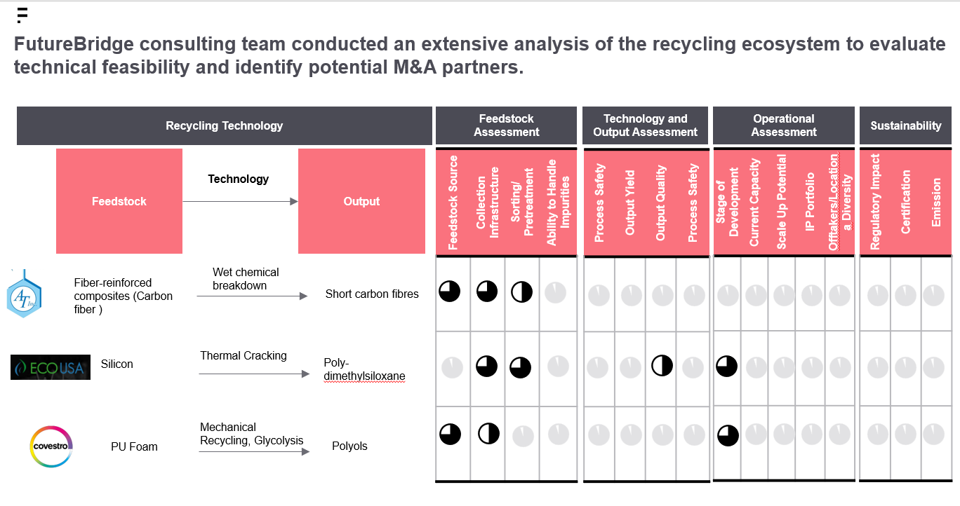

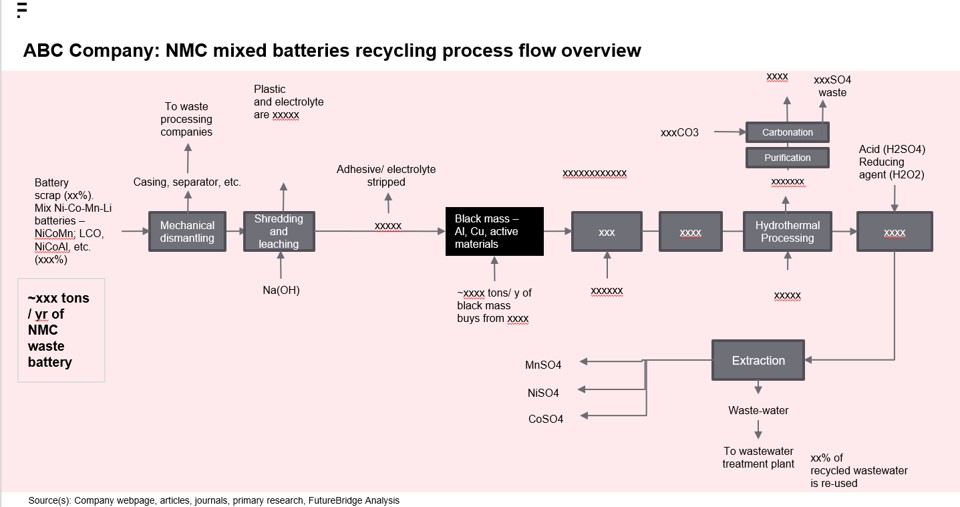

- Technological Feasibility: Assessed and recommended suitable recycling technologies for specific polymer waste streams.

- Regulatory Compliance: Provided insights and solutions to meet recycling content and environmental regulations.

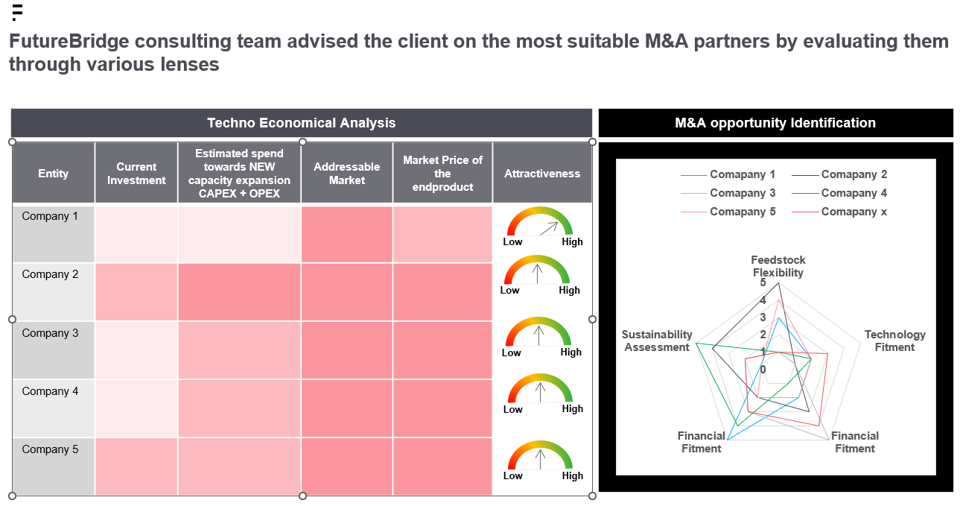

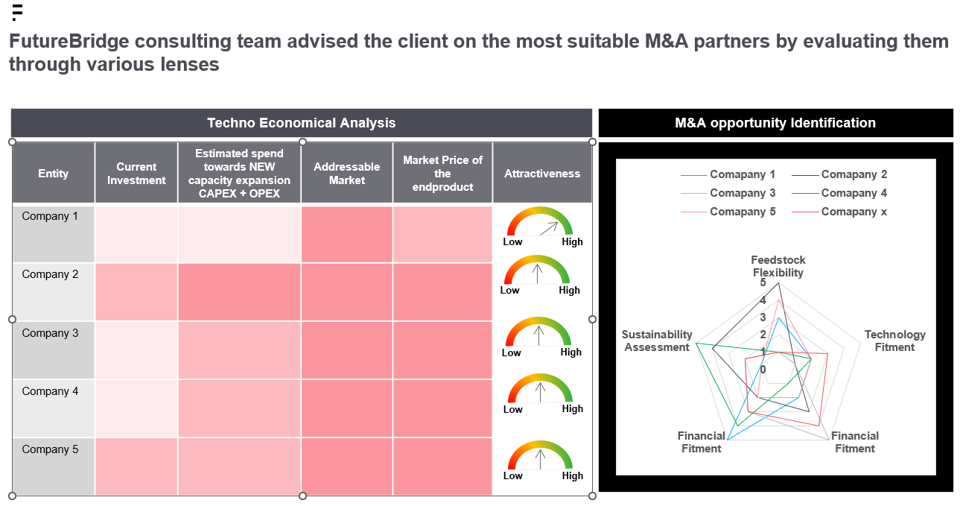

- M&A Opportunity Identification: Identified ideal recycling partners based on technical fit, sustainability, location, and business alignment.

- Techno-Economic Assessment: Evaluated the economic viability of shortlisted options, comparing CAPEX, OPEX, technology complexity, yield ratio, credibility, output product slate, and market size amongst other factors.

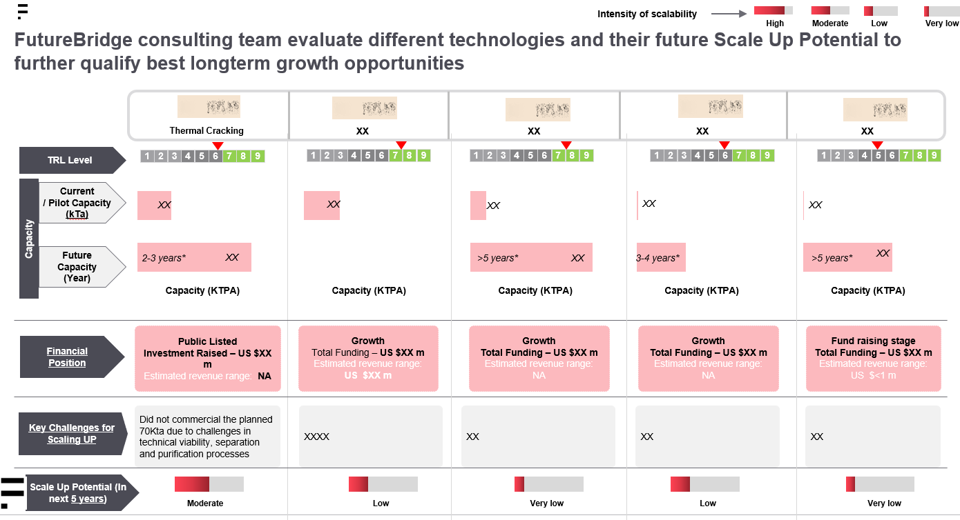

- Supply Chain Integration: Developed strategies for seamless incorporation of recycled materials into the existing supply chain, optimizing the ecosystem for various locations after considering waste stream properties and volumes.

FutureBridge services enabled the client to develop comprehensive recycling strategies, including securing feedstock, identifying optimal technology pathways, and finding collaboration partners across the value chain. Our techno-commercial assessment of the thermosetting polymer recycling value chain empowered the client to make strategic short and long-term decisions by providing them with comprehensive foresight into recycling solutions.

Contact us today to leverage our expertise and experience in thermosetting polymer recycling innovations and accelerate your future sustainable, circular supply-chain.