Product-as-a-Service, the Shifting Model in Industrial Machinery

Industrial Equipment

Industrial Equipment

What triggered the migration from transactional to contractual selling?

Industrial ‘Machinery & Equipment’ manufacturers are shifting their focus from selling physical equipment to value-added services based on their equipment’s core capabilities. This trend has given rise to a new type of business model called Product-as-a-Service (PaaS), also known as Servitization. In this model, manufacturers are compensated for providing output- or outcome-based service packages to their customers.

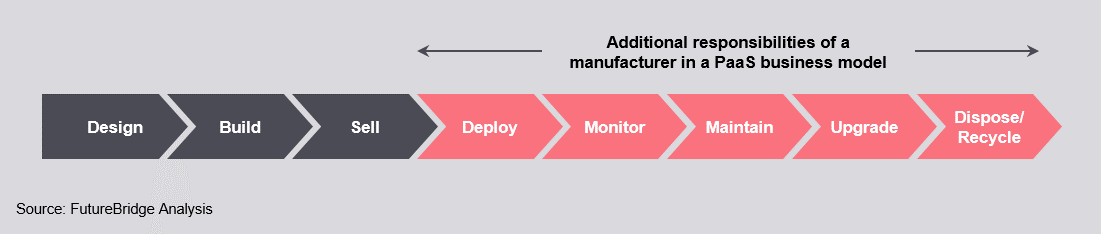

The figure below indicates how PaaS provides higher profit margin and stable income, as it enables the industrial machinery manufacturer to be a part of an entire product’s lifecycle

According to findings in 2018, 75%1 of companies expect that delivering services would become a more significant part of their business in the next three to five years. With the growing adoption and innovation in the PaaS business model, there are changes expected in the way manufacturers strategize to generate new revenue streams.

Note: 1Survey based on interviews with more than 70 industrial engineering companies.

What are manufacturers strategizing on?

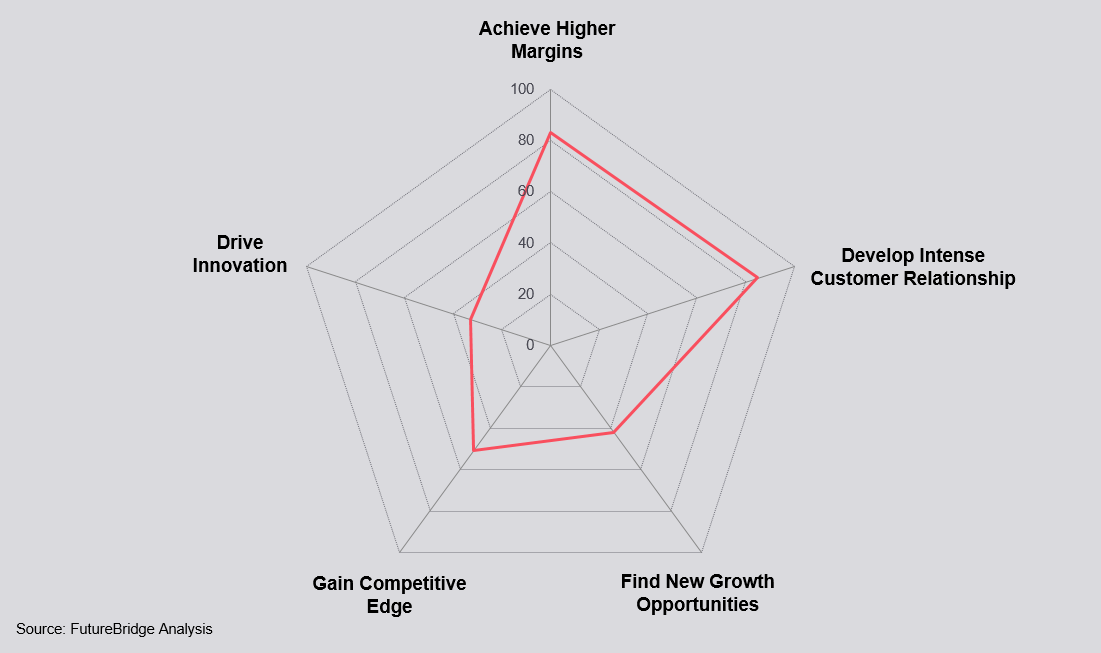

Industrial machinery manufacturers are expected to adopt PaaS, mainly due to the following five reasons:

- Achieve Higher Margins and a Constant Source of Revenue: Shrinking product-based profit margins is anticipated to spur the need for launching service-based PaaS business models. EBIT margin generated by service-based models is 3-7 times higher as compared to new equipment sales. Moreover, unlike new equipment sales, PaaS generates constant revenue for the manufacturer, even during an economic crisis or down-sizing.

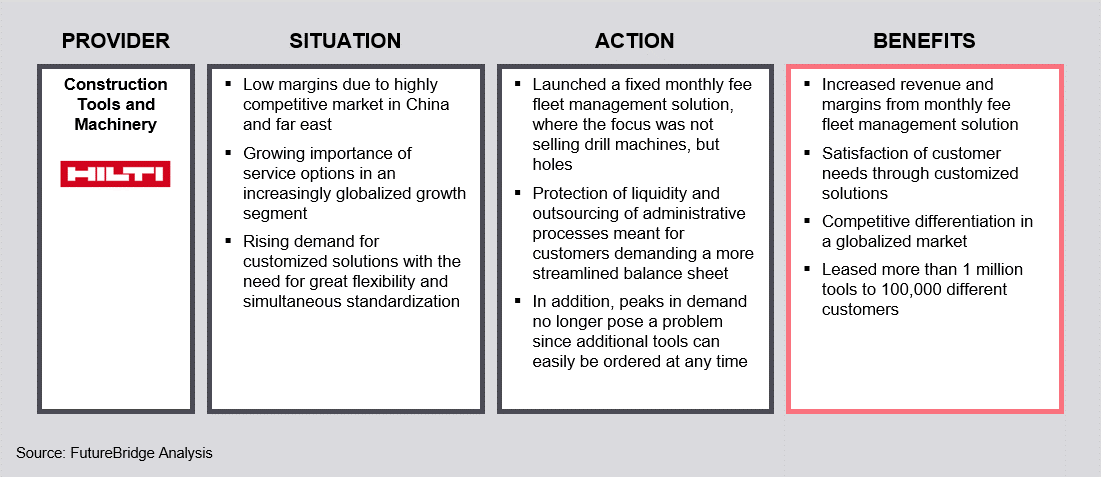

The figure below indicates how Hilti increased its profit margin and developed a continuous source of revenue by introducing a monthly chargeable PaaS model.

- Develop Intense Customer Relationship: Services have become an integral part of the proposition, playing an important role in the customers’ purchase decision. PaaS models offer an opportunity for the manufacturer to establish long-term leasing contracts (generally 5 years or more) and enable sustainable and stable customer relationships.

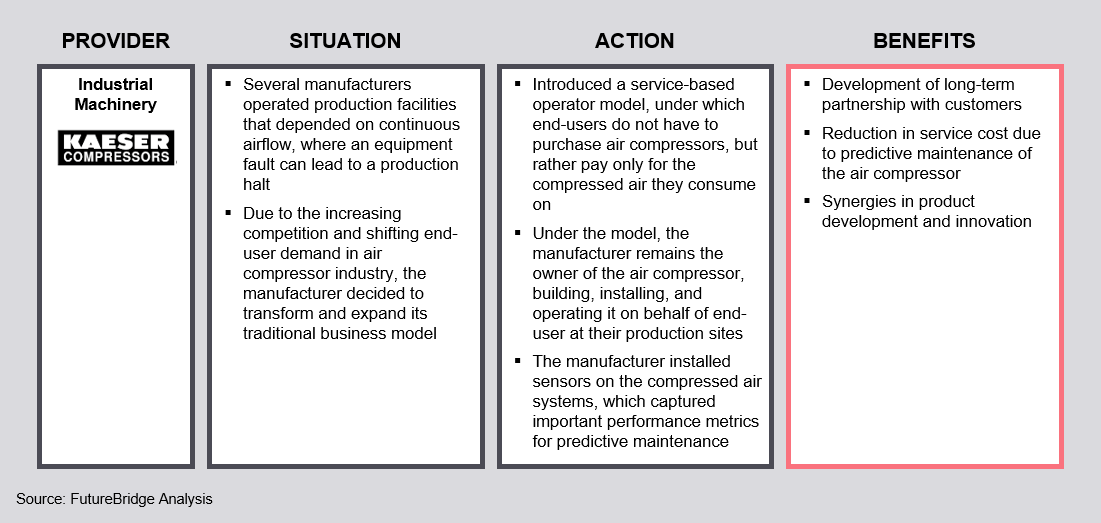

The figure below indicates how KAESER developed a long-term partnership with its customers by launching a service-based operator model which charges customers based on their compressed air usage.

Gain Competitive Edge: PaaS models can be used by manufacturers to differentiate their equipment and achieve high customer satisfaction. Offering a PaaS package enables manufacturers to complement their core asset with services, thereby protecting their businesses from being disrupted by new aggressive competitors.

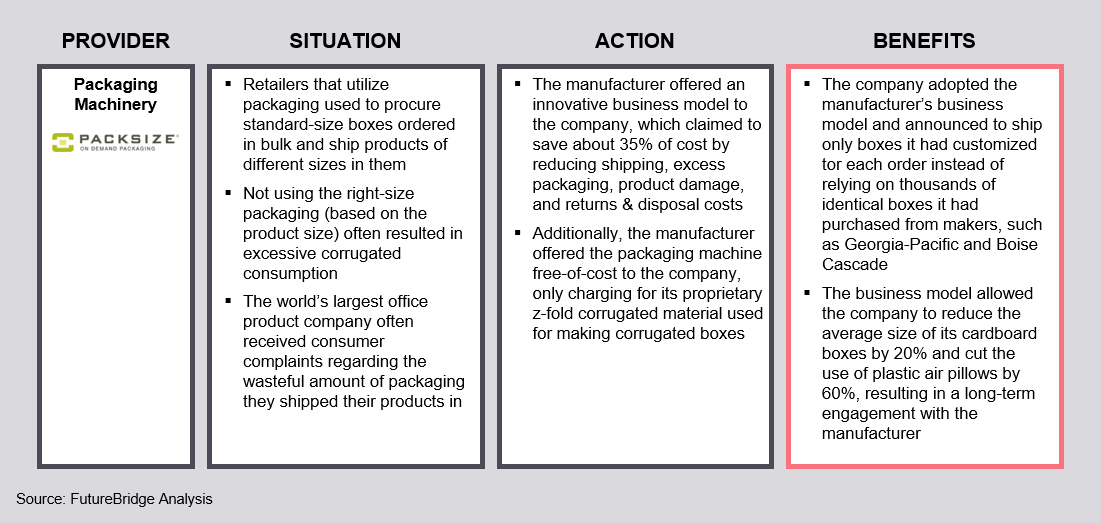

The figure below indicates how Packsize offers an on-demand packaging solution to the world’s largest office product company to gain a competitive edge among traditional box providers

- Drive Innovation: Some PaaS models allow manufacturers to outfit the equipment with sensors and monitor its performance. This will enable them to gather performance metrics and alter designs of upcoming models to address the changing requirements of customers.

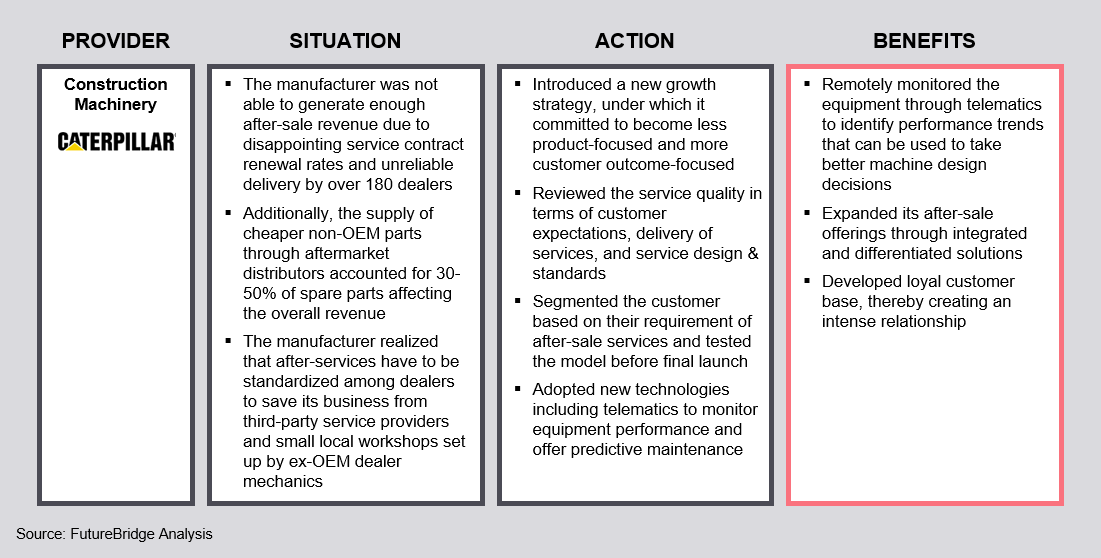

The figure below indicates how Caterpillar servitized its business by offering a remote tracking and monitoring service to analyze its equipment performance trends for using them for future innovation.

New Growth Opportunities: By offering services, companies can acquire insights into customer needs, which can further be used to design and market appropriate equipment in the industry.

The figure below represents motivating factors for manufacturers to offer PaaS models; among these, achieving higher margins and developing intense relationship with the customer have been the leading motivating factors.

What is expected in the next three years?

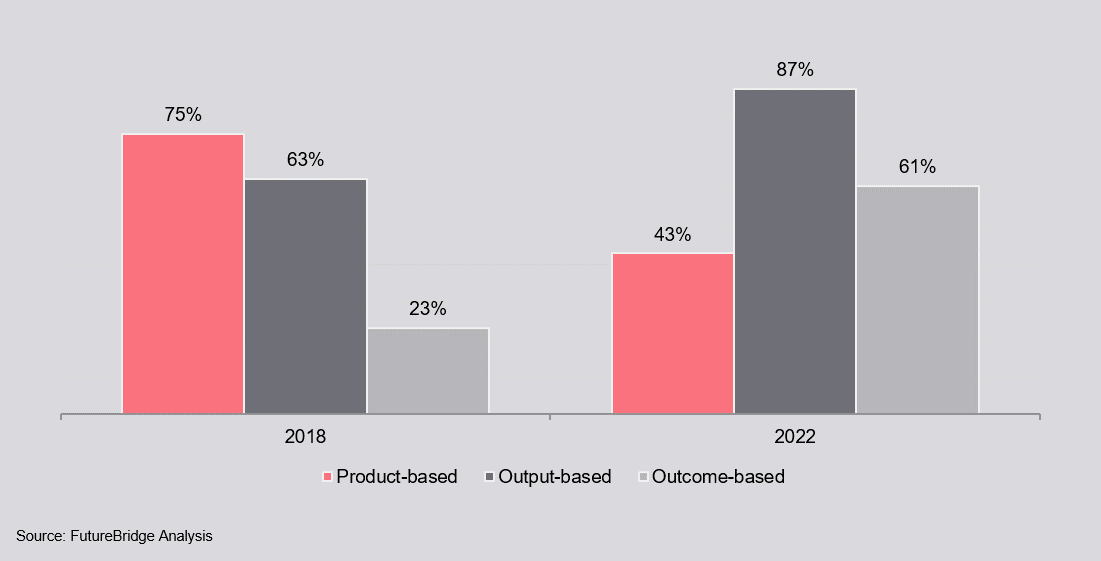

Service models can be mainly of three types, namely, product-based, output-based (price per output), and outcome-based (price per result achieved). Among these, outcome-based and output-based services fall under a PaaS model.

Output-based model is expected to be used by most of the manufacturers to offer PaaS offerings2 by 2022, as indicated in the figure below.

Note: 2Survey based on interviews with more than 70 industrial engineering companies.

Based on findings, most manufacturers expect to increase the share of their output and outcome-based PaaS offerings in the next three years. At present, very few industrial machinery manufacturers are providing outcome-based PaaS models to avoid taking full responsibility for a client’s production facility.

What should manufacturers focus on?

- It is advisable for manufacturers to be aware of customers’ demand and transform when the opportunity is right.

- Manufacturers planning to offer PaaS models must pay attention to their corporate image prior to pitching PaaS services to customers.

- An ideal customer organization for a PaaS offering should have a high appetite for outsourcing; hence, manufacturers may not target customers who already have a large set-up for in-house maintenance.

- Pitching PaaS offering to a customer is not only about selling the equipment but also enabling them to buy the proposed services that are compelling and hard to refuse. Selling PaaS models that are mostly customized, based on the individual need of different customers, often require additional consultative selling skills.

- Industrial manufacturers may employ any of the three types of mechanisms to form pricing for PaaS models. These mechanisms are usage-based mechanism (how the customer utilizes the equipment), performance-based mechanism (how well the manufacturer performs), and output-based mechanism (how much business value the equipment creates for the customer).

5 min read

5 min read