Artificial Intelligence in Industrial Machinery

Industrial Manufacturing

Industrial Manufacturing

Adoption of Artificial Intelligence in Industrial Machinery

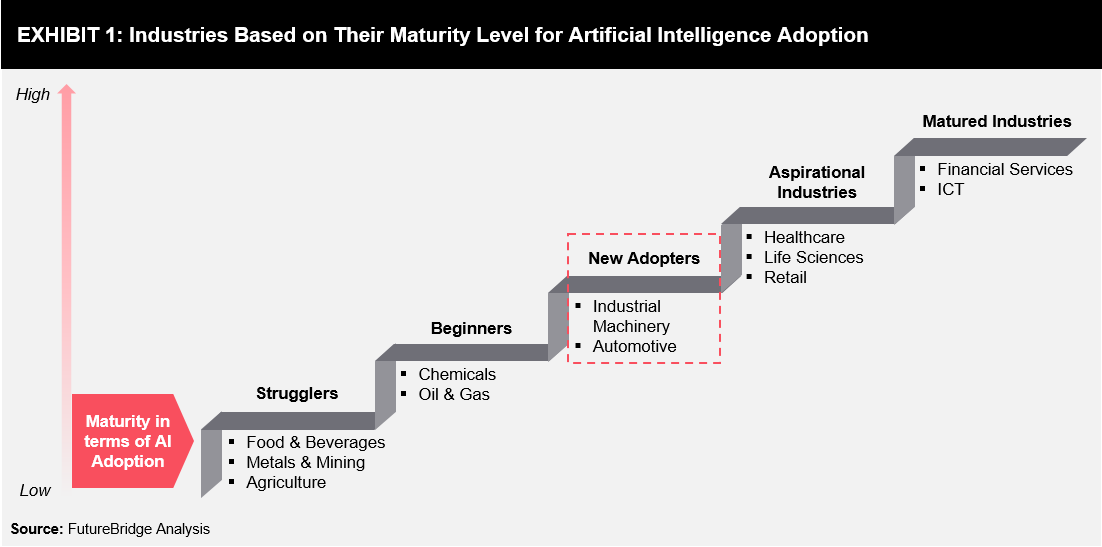

Over the last 10 years, the adoption of artificial intelligence has grown significantly in most of the industries; however, in the Industrial Machinery (IM) industry, it is still in the early stages and can be considered as new adopters (refer Exhibit 1).

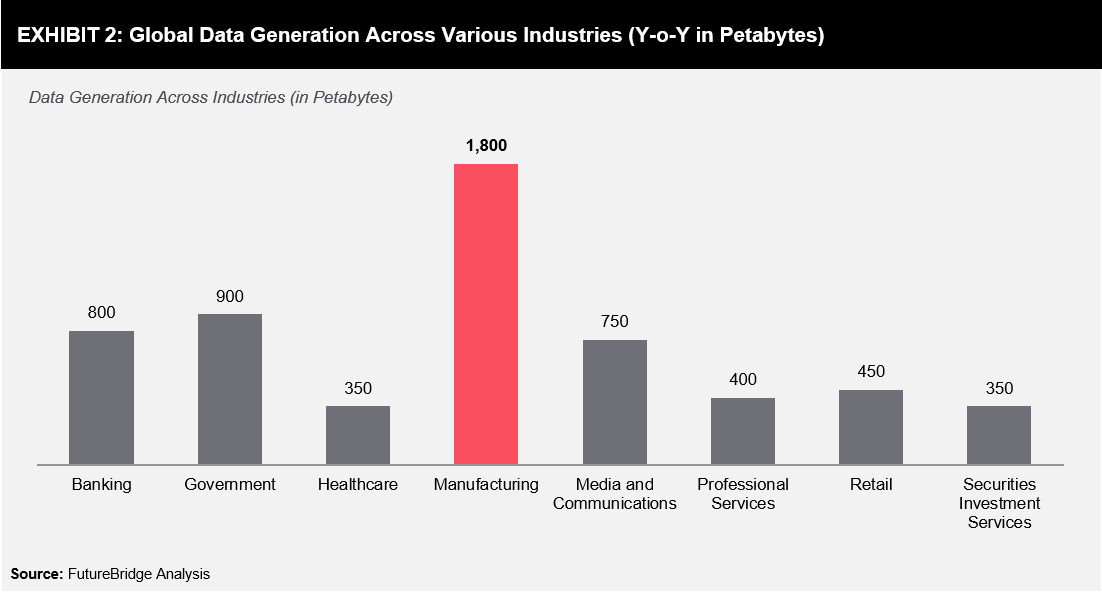

Data is the key element in artificial intelligence. Manufacturing shop floors, where a majority of the industrial machinery is utilized, is one of the most data-rich environments, creating 1.8k petabytes of data annually (refer Exhibit 2). Traditionally, extraction and effective utilization of this data have remained a challenge for the IM industry.

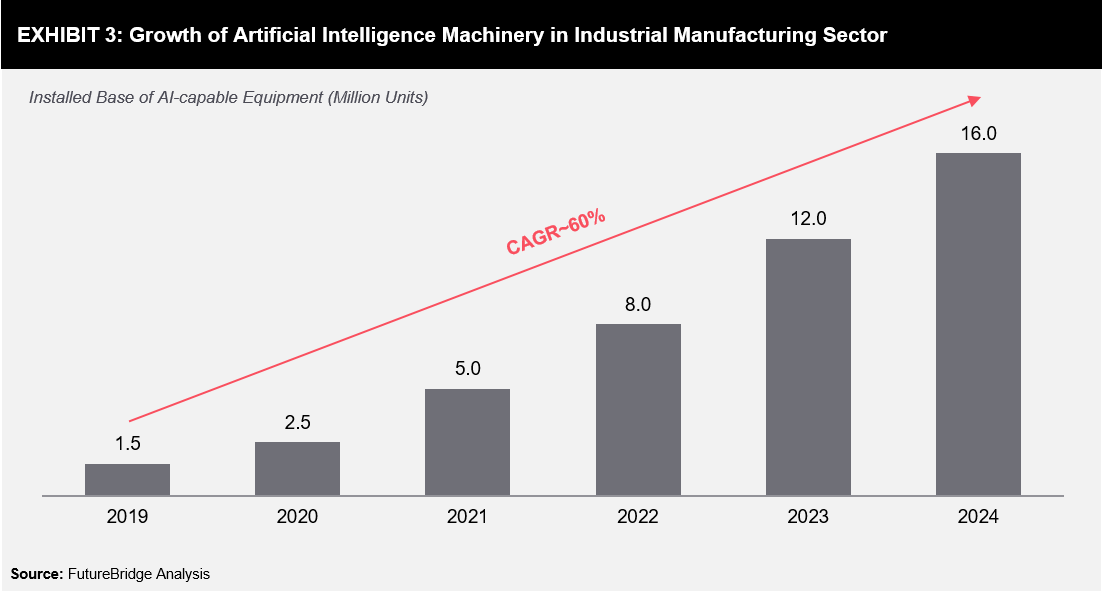

However, with the widespread deployment of sensors and IoT devices, this trend is expected to change at a rapid pace. The installation base of artificial intelligence-capable machinery in the industrial manufacturing sector is expected to reach 16 million units by 2024, growing at a CAGR of 60% (refer Exhibit 3).

Applications of Artificial Intelligence in the Industrial Machinery Industry

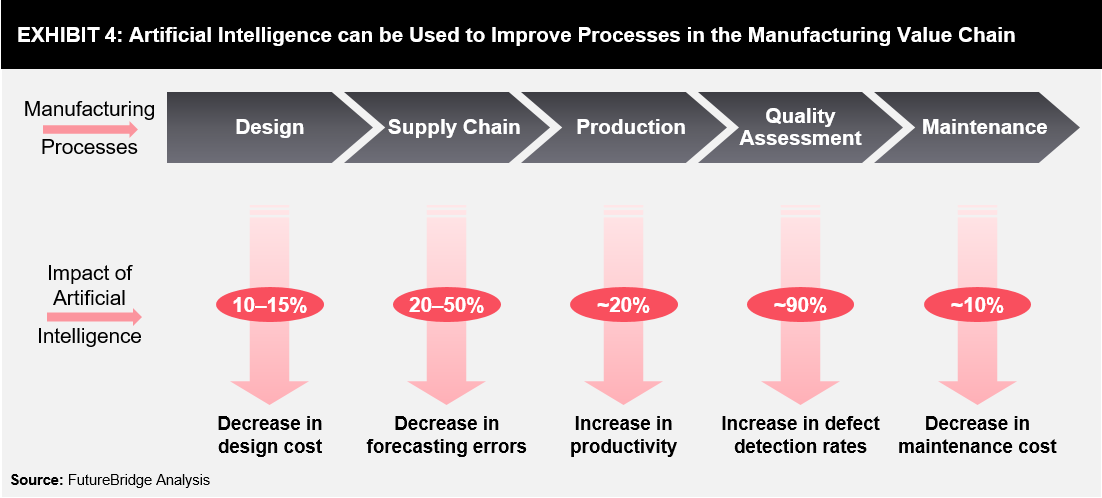

While artificial intelligence is poised to transform several industries, the technology is well-suited for industrial machinery. Artificial intelligence can assist the entire manufacturing value chain (refer Exhibit 4).

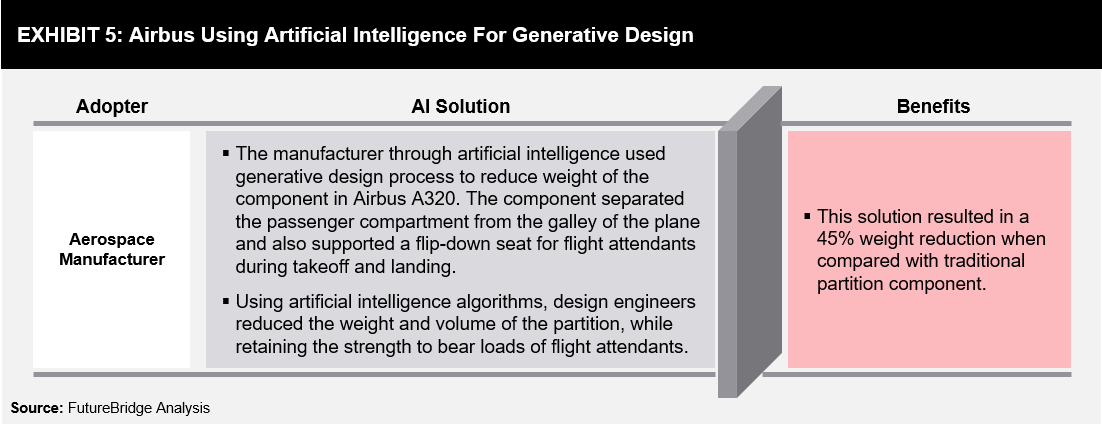

Design: Through artificial intelligence, designers can define a problem via objectives and constraints (using generative design), and later allow the system to come up with different solutions.

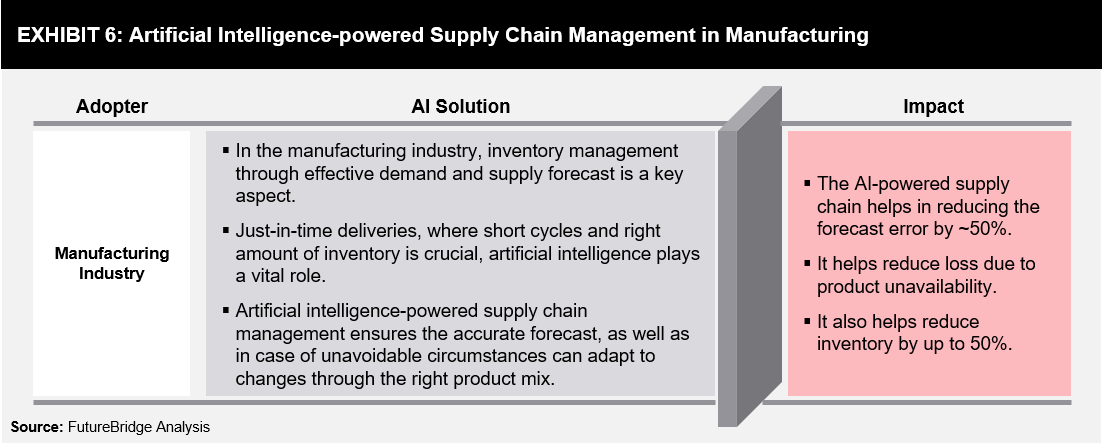

Supply Chain: Machinery manufacturers have complex supply chains, accounting for multiple components from various tier 1 manufacturers. Delay in the delivery of these components can result in ceasing the production. Artificial intelligence can be used by manufacturers to better predict the complex interactions between each production unit and automate order requests for components.

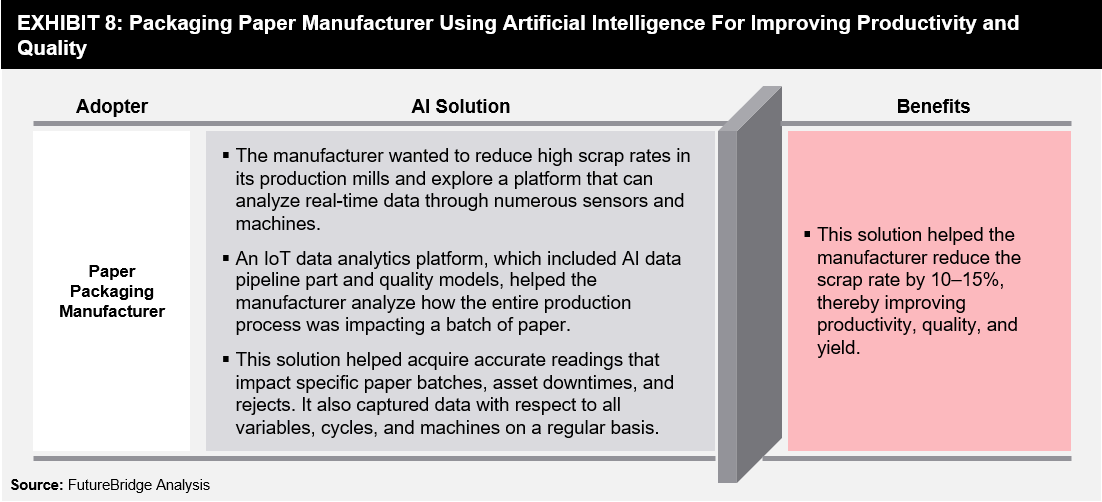

Production: Artificial intelligence can enable manufacturers to improve productivity. In addition, it can introduce collaborative and context‑aware robots across the manufacturing floor. These robots utilize computer vision and artificial intelligence to operate alongside humans in shared environments.

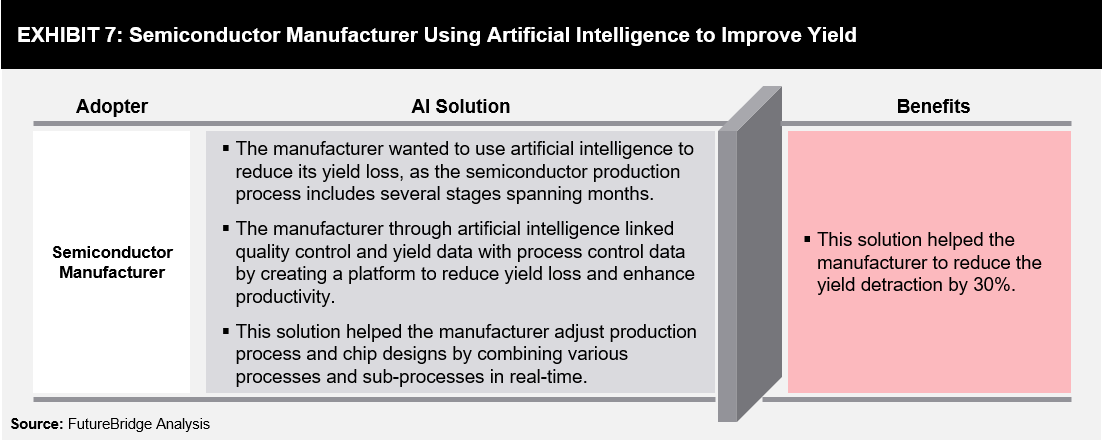

Quality Assessment: Artificial intelligence has opened the door for new quality procedures in manufacturing. Manufacturers can utilize machine learning and advanced image recognition systems to automate the visual inspection and fault detection of small components of the equipment. Faulty components are rejected from the production line yielding significant savings for the manufacturer.

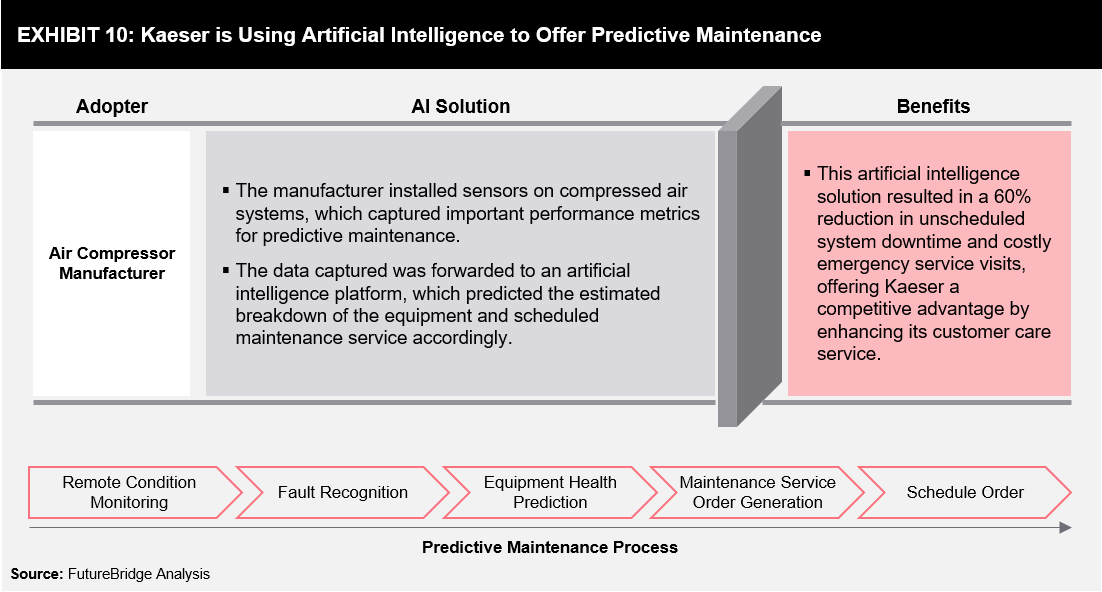

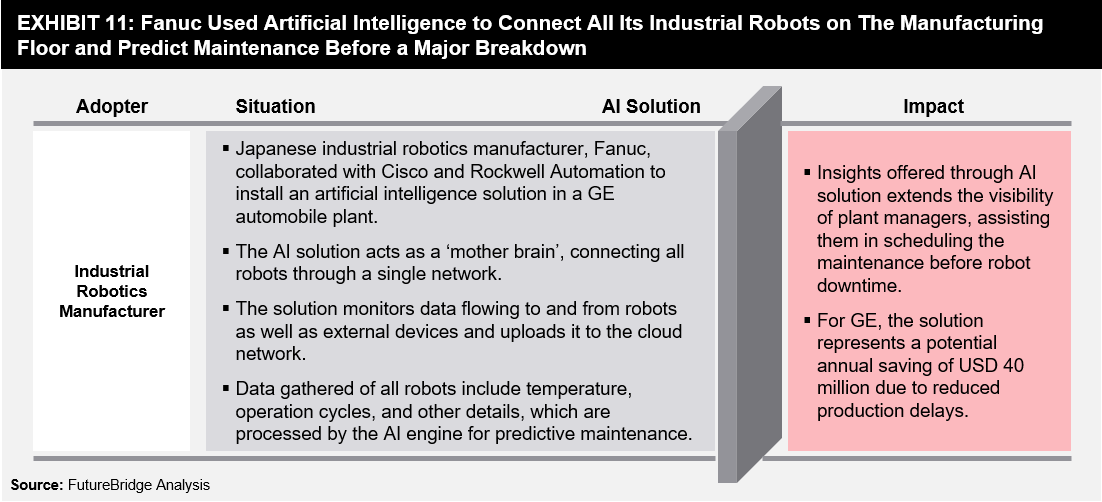

Maintenance: Industrial machinery manufacturers can use artificial intelligence in conjunction with IoT data to predict and avoid machine failure. Sensors installed in the equipment gather data regarding its operation and send it to the artificial intelligence, which utilizes condition-based indicators to predict the estimated breakdown of the equipment.

Road Ahead

Going ahead, applications of artificial intelligence would increase in other processes as well. One of the main applications of artificial intelligence that is expected to gain traction during the forecast period would be quality assessment. The total installed base of artificial intelligence-capable equipment used for quality assessment is expected to witness a CAGR of > 60% during the forecast period. Some key pointers that manufacturers should focus on are:

- Execute pilot projects to gain experience, build a team, and work on a defined strategy: Manufacturers can start a pilot project if it can meet the following targets:

- Can be executed by a new artificial intelligence team and start achieving results within the first 6-12 months

- Conducting thorough due diligence; the project should be technically feasible

- Should have defined objective with a business value

- Offer in-house artificial intelligence training: Manufacturers can offer artificial intelligence training based on the level of designation of an employee. For instance:

- Executives and business leaders can be offered a 5–8 hours training on basic understanding of artificial intelligence, its impact on corporate strategy, and its applications

- Division heads can be offered a 10–15 hours training encompassing basic understanding, major classes of algorithms, artificial intelligence workflow and processes, roles and responsibilities in artificial intelligence teams, and team management

- Artificial intelligence engineer trainees should be offered a 50–80 hours training on deep technical understanding and available tools for building artificial intelligence as well as implementing workflows

4 min read

4 min read