Future of Flexible Electronics in Mobility

Listen to this Article

mins | This voice is AI generated.

mins | This voice is AI generated.

A technology that for a long time seemed restricted to the realms of science fiction is rapidly becoming a reality. Recent years have seen industry-leading companies releasing products that incorporate flexible electronics that bend and fold to expand capabilities vis-à-vis exploring diverse applications that were not possible earlier.

Flexible electronics hold significant promise for the mobility industry. A substantial rise in the use of thin electronics on flexible substrates will be triggered by the need to reduce the weight of electric vehicles, a primary concern for the production of EVs. The conformality of flexible electronics is also well-suited to emerging tastes in automotive interior design that prefer organic curves over flat surfaces.

Three main technological transitions that are accelerating increased adoption of Flexible Electronics today are –

With the designing benefits, the possibilities of flexible electronic devices are endless. Quite fascinating to Imagine having tiny smartphones that wrap around our wrists and flexible displays that fold out as large as a television.

In addition to their flexibility, flexible electronics might cost less to manufacture. Researchers have gone on record to claim that over the years, it will be possible to print flexible electronics on a plastic film in the same way as we print ink on newspapers today.

“If flexible electronics become cheap enough, we could have thrown away electronic products. An individual might wear the phone on clothing, or run a bio-assay to assess health simply by wiping nose with a tissue.” says an assistant professor of chemical engineering at Penn State, Enrique Gomez.

The advantages of Flexible Electronics are many, which have resulted in numerous exciting applications. Some of the notable applications of flexible electronics have been, of which, many have been developed –

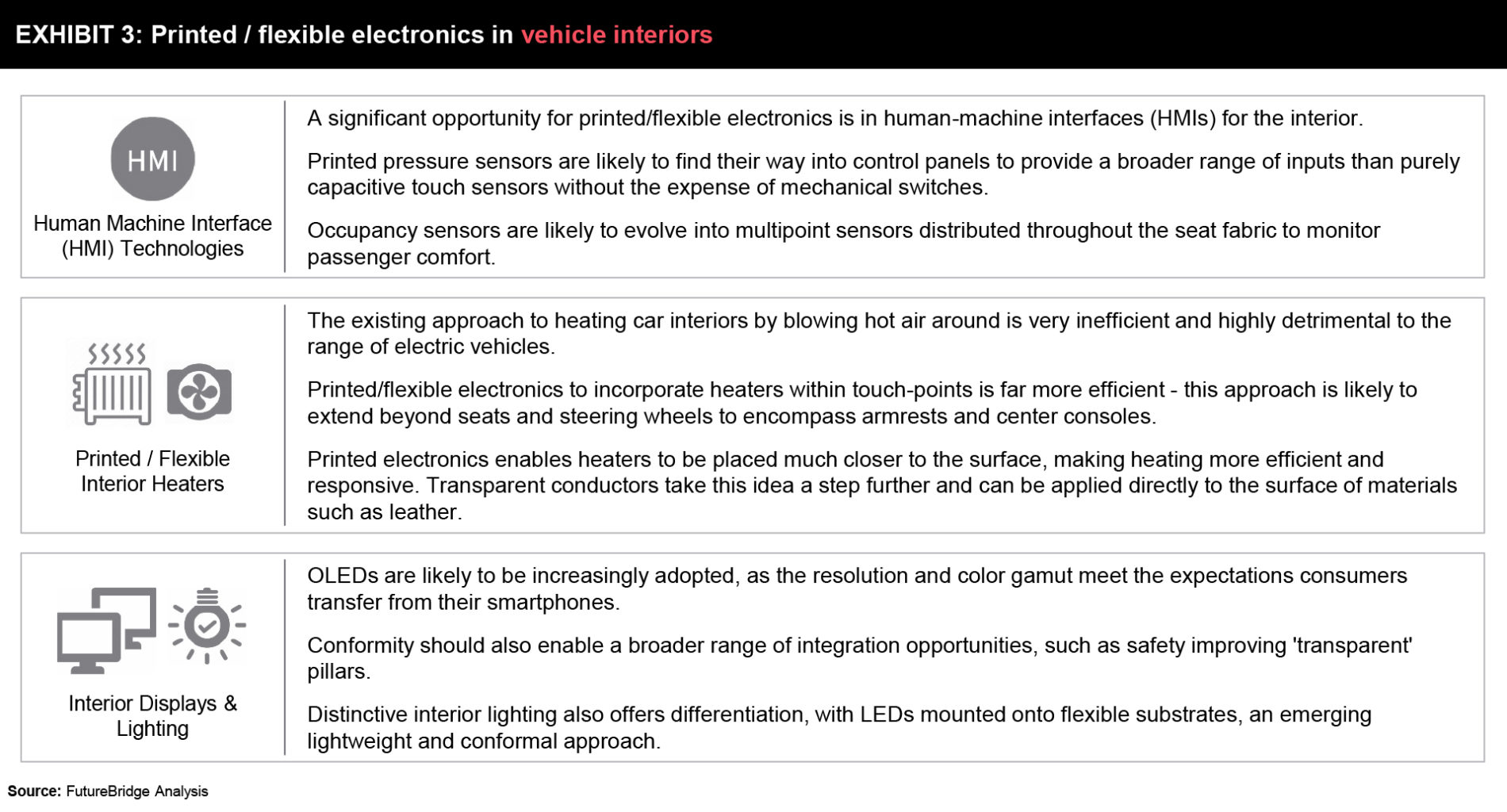

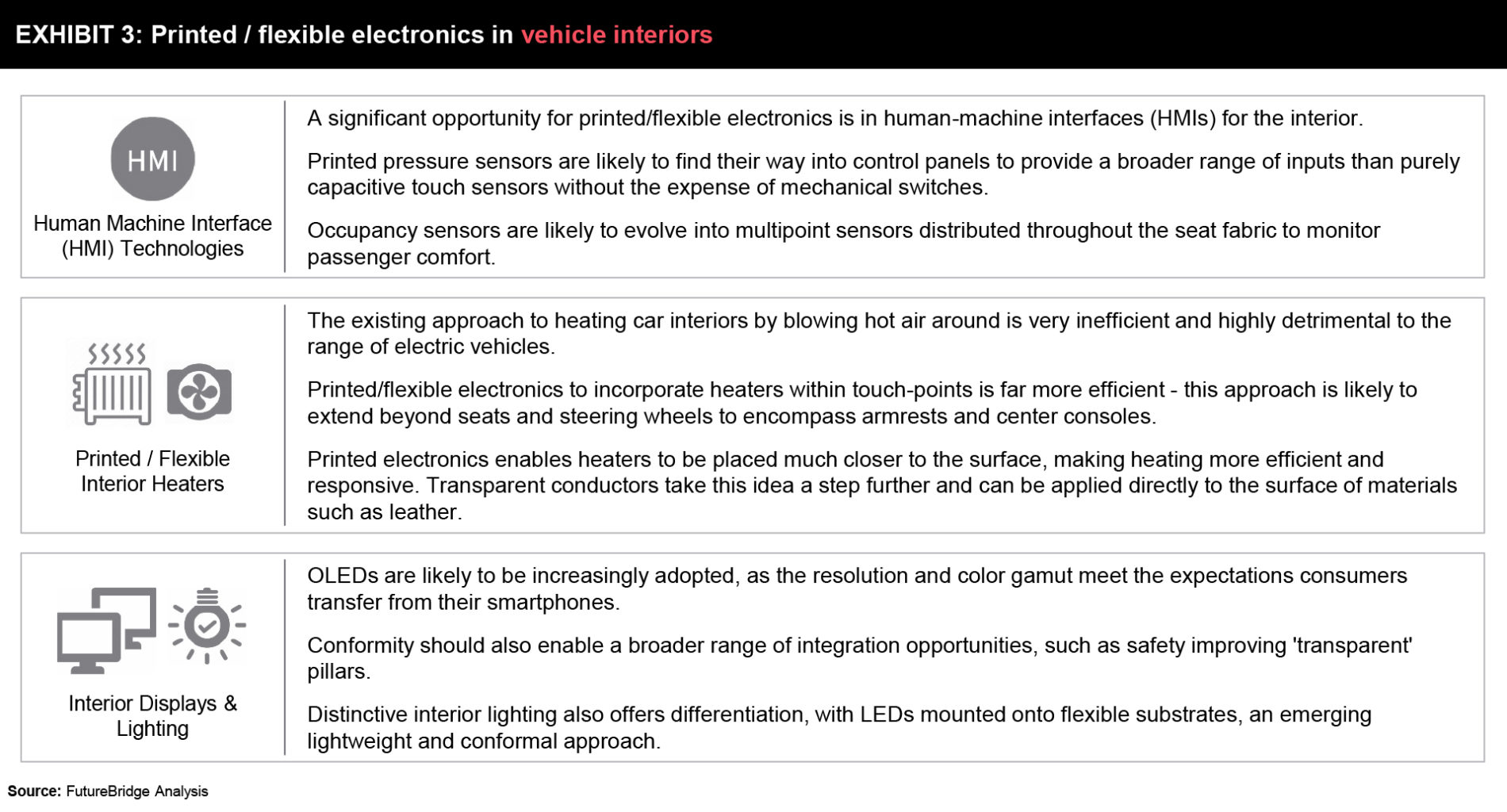

The automotive OEMs and suppliers are exploring diverse applications of Flexible Electronics. Mainly from a mobility industry’s perspective, the applications are electric vehicle powertrains, vehicle interiors, and vehicle exteriors. Below presented are a set of exhibits that showcases some of these promising use-cases.

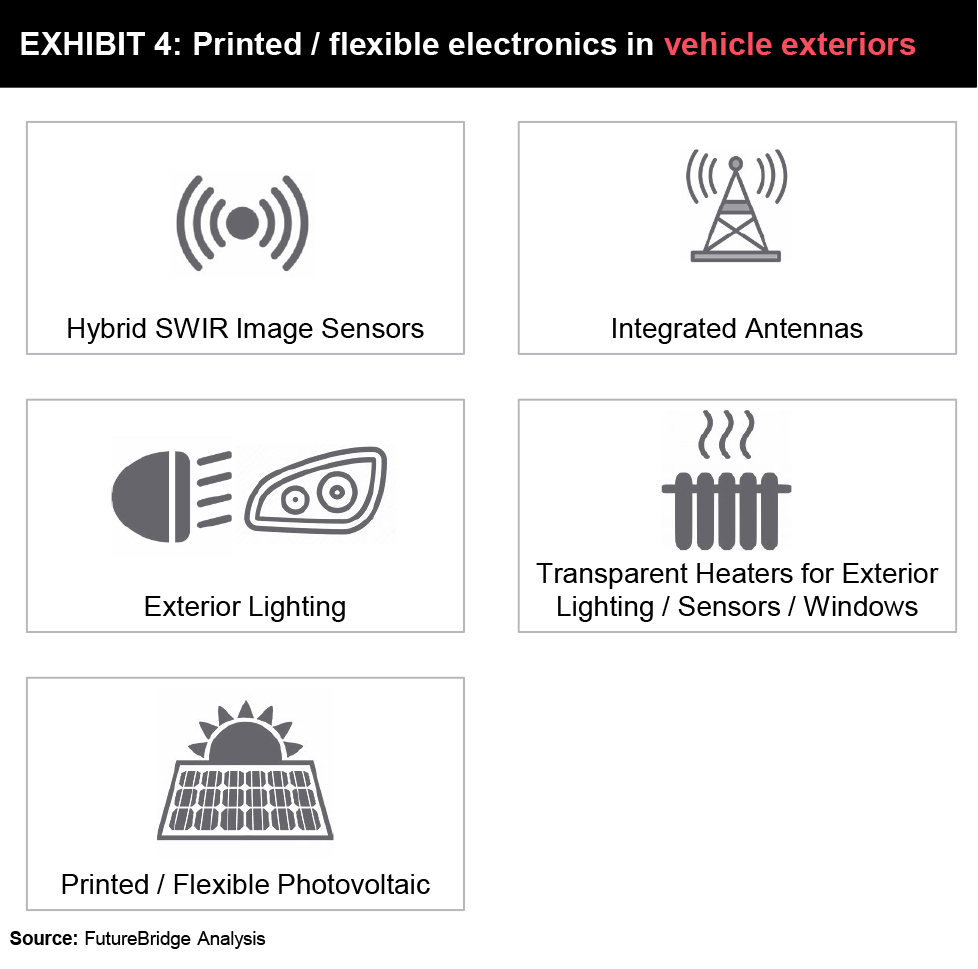

In the last few years, automotive companies have experimented with flexible electronics to develop some exciting vehicle exterior applications. An exhibit shown below presents a glimpse of few such applications –

Hybrid SWIR (Short-wave Infrared) Image Sensors – ADAS systems and future autonomous vehicles will require a lot of input information (from the surrounding environment) to ensure safety.

Imaging in the SWIR spectral region is particularly promising since light scatters less at longer wavelengths, which enables objects to be identified in fog or dust at longer distances. As of today, the incumbent technology for SWIR image sensors is prohibitively expensive. Coating silicon read-out circuits with either quantum dots or organic semiconductors can be a highly promising approach.

Integrated Antennas – Every year, vehicles are becoming more and more connected, necessitating the use of several antennas to cover diverse frequencies. These antennas need to be integrated into body panels made of plastics, hence creating opportunities for in-mold electronics, and printing them onto 3D surfaces/substrates. In the future, we may start seeing transparent antennas installed on windows.

Exterior Lighting – With advancements in vehicle autonomy, they will need to interact with the pedestrians. Low-cost flexible/printed displays are perfectly suited for this purpose. As durability, low weight, and conformality (including in an accident) will be more important than simply resolution. Possible approaches may include mounting LEDs on flexible substrates and printed LEDs.

Transparent Heaters for Exterior Lighting / Sensors / Windows – Cameras and LIDAR in ADAS systems or autonomous vehicles will always need a clear view of the road ahead. Ensuring that the transparent cover over a sensor is free of mist/frost will become extremely important.

Furthermore, thin metal lines could obscure the view of these safety-critical systems. Developing transparent heaters that use transparent conductors such as CNTs or silver nanowires will be needed. Over time, the cost of these technologies is likely to fall, enabling them to be applied to windows.

Printed / Flexible Photovoltaics – While photovoltaics may never be able to power a car continuously over long distances, they can surely enable around 30 km of distance to be added each day. EVs with solar panels use silicon photovoltaics, but thin-film photovoltaics are a promising alternative due to their lightweight and conformality.

Future ahead for flexible electronics’ roleplay in the mobility industry

At various trade shows, flexible technologies are demonstrated, but manufacturers tend to show off a single function – a stretchable circuit here, a rollable screen there. In the real world, gadgets need to bundle such features into a neat package, which is a sticking point for the designers.

Researchers are also looking to develop flexible electronic devices by experimenting with a variety of materials for the capacitors; a few of these are mentioned here:

Flexible plastic sheets – smaller capacitors could be deposited directly onto flexible plastic sheets and sandwich in the flexible circuit boards. This way, the capacitors do not hog valuable surface area.

Ceramics – while thick ceramics tend to crack, researchers can apply them as zigzags, so they deform more easily. Ceramics is the crucial ingredient in capacitors that can be used to regulate voltage in electronic circuits.

Organic molecules – organic molecules can be the ultimate flexible materials. While most organics are insulators, a few are conductive. The endeavor is to turn these molecules into transistors and photovoltaic cells so they can conduct electricity.

Despite these obstacles, we can expect flexible electronics to improve over the coming years gradually. Electronic components will become more flexible, circuits will demand less power, and materials will make flexible devices more pleasant to interact with.

Share your focus area or question to engage with our Analysts through the Business Objectives service.

Submit My Business ObjectiveOur long-standing clients include some of the worlds leading brands and forward-thinking corporations.